Technology for separating and purifying trifluoroiodomethane

A trifluoroiodomethane and trifluoromethane technology, which is applied in the field of separation, purification and recovery of trifluoroiodomethane and trifluoroiodomethane mixed gas, can solve the problem of high saturated vapor pressure of the gas, and achieve high operating flexibility and low operating cost Low, low residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

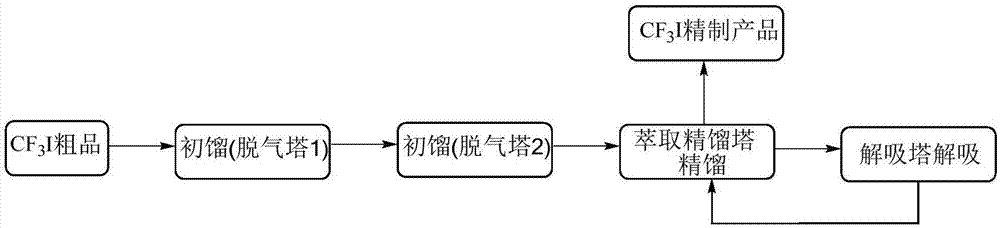

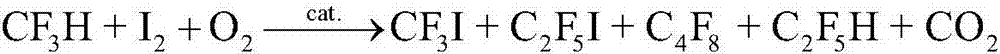

Embodiment 1

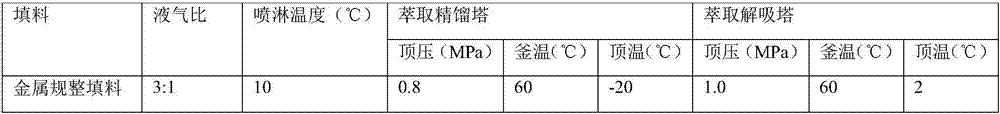

[0035] Will CF 3 I crude product is passed into degassing tower 1 (filler is wire mesh) initial distillation and removes non-condensable gas, the temperature of the tower top circulation cooling liquid of degassing tower 1 is-20 ℃, and tower still temperature is 30 ℃, and the temperature of degassing tower The pressure is 0.1MPa; the CF after removing the non-condensable gas 3 I crude product passes into degassing tower 2 to remove CF 3 H and C 2 f 5 For gases such as H, the temperature of the circulating cooling liquid at the top of the degassing tower 2 (the packing is wire mesh) is -45°C, the temperature of the tower bottom is 60°C, and the pressure of the degassing tower is 0.5MPa. CF after two degassing 3 I crude product is passed into extractive distillation column, and extractant is acetone, carries out extraction rectification according to the process parameter of table 1, and purity is 99.96% CF 3 I monomer is recovered from the top of the tower, and the bottom o...

Embodiment 2

[0039] Will CF 3 I crude product is passed into degassing tower 1 (filler is Raschig ring) initial distillation and removes non-condensable gas, the temperature of the tower top circulation cooling liquid of degassing tower 1 is-30 ℃, and tower still temperature is 40 ℃, and the temperature of degassing tower The pressure is 0.3MPa; the CF after removing the non-condensable gas3 I crude product passes into degassing tower 2 to remove CF 3 H and C 2 f 5 For gases such as H, the temperature of the circulating cooling liquid at the top of the degassing tower 2 (the packing is Raschig rings) is -40°C, the temperature of the bottom of the tower is 70°C, and the pressure of the degassing tower is 0.7MPa. CF after two degassing 3 1 crude product is passed into extractive distillation column, and extractant is methyl acetate, carries out extraction rectification according to the processing parameter of table 2, and purity is 99.99% CF 3 I monomer is recovered from the top of the t...

Embodiment 3

[0043] Will CF 3 I crude product passes into degassing tower 1 (filler is a glass spring) initial distillation removes non-condensable gas, the temperature of the tower top circulation cooling liquid of degassing tower 1 is-40 ℃, and tower still temperature is 65 ℃, and the pressure of degassing tower is 0.8MPa; the CF after removing the non-condensable gas 3 I crude product passes into degassing tower 2 to remove CF 3 H and C 2 f 5 For gases such as H, the temperature of the cooling liquid at the top of the degassing tower 2 (filler is glass spring) is -35°C, the temperature of the bottom of the tower is 55°C, and the pressure of the degassing tower is 0.5MPa. CF after two degassing 3 I crude product passes into extractive rectification column, and extractant is methyl ethyl ketone, carries out extractive rectification according to the process parameter of table 3, and purity is 99.95% CF 3 I monomer is recovered from the top of the tower, and the bottom of the tower is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com