Preparation method of vinylidene fluoride and preparation method of catalyst used by same

A vinylidene fluoride and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, preparation of halogenated hydrocarbons, etc., can solve difficult maintenance, poor product selectivity, and low conversion rate. and other problems, to achieve good economic and social benefits, improve selectivity and yield, and improve the effect of conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

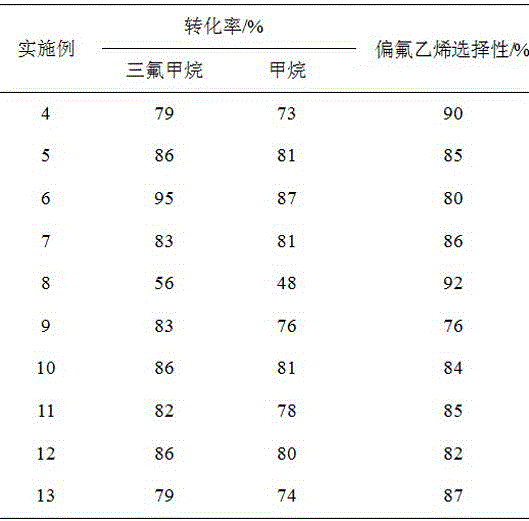

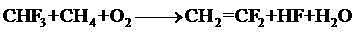

[0028] Pass trifluoromethane, methane and oxygen into the reactor without catalyst at a ratio of 1:1:0.25 (molar ratio), at a temperature of 850°C, a pressure of 2bar, and a space velocity of 5000h -1 Under the conditions of the reaction, the conversion rate of trifluoromethane is 52%, the conversion rate of methane is 48%, the selectivity of vinylidene fluoride is 67%, other main by-products are tetrafluoroethylene, and other small by-products are ethylene, ethane , difluoromethane, monofluoroethylene, trifluoroethylene and hexafluoropropylene.

Embodiment 2

[0030] Pass trifluoromethane, methane and oxygen at a ratio of 1:1:0.25 (molar ratio) into a reactor containing 50ml of lanthanum oxide catalyst, at a temperature of 850°C, a pressure of 2bar, and a space velocity of 5000h -1 react under the conditions. The conversion rate of trifluoromethane is 89%, the conversion rate of methane is 78%, the selectivity of vinylidene fluoride is 87%, other main by-products are tetrafluoroethylene, and other small by-products are ethylene, ethane, difluoromethane, a Fluoroethylene, trifluoroethylene and hexafluoropropylene.

Embodiment 3

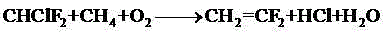

[0032] Feed nitrogen, difluorochloromethane, methane and oxygen into a reactor containing 50ml of cerium oxide catalyst at a temperature of 700°C, a pressure of 2bar, and a space velocity of 5000h at a ratio of 20:2:2:1 (molar ratio). -1 react under the conditions. The conversion rate of difluorochloromethane is 100%, the conversion rate of methane is 38%, the selectivity of vinylidene fluoride is 57%, and other main by-products are trifluoromethane, acetylene, ethylene, tetrafluoroethylene, ethane, and other small by-products The products are ethylene, ethane, difluoromethane, monofluoroethylene, trifluoroethylene and hexafluoropropylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com