Fabric softening agent

A fabric softener and oligomer technology, applied in the field of fabric softeners, can solve the problems of oil spots, silicone oil spots, hard hand feeling, etc., achieve soft hand feeling, prevent demulsification, and increase hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

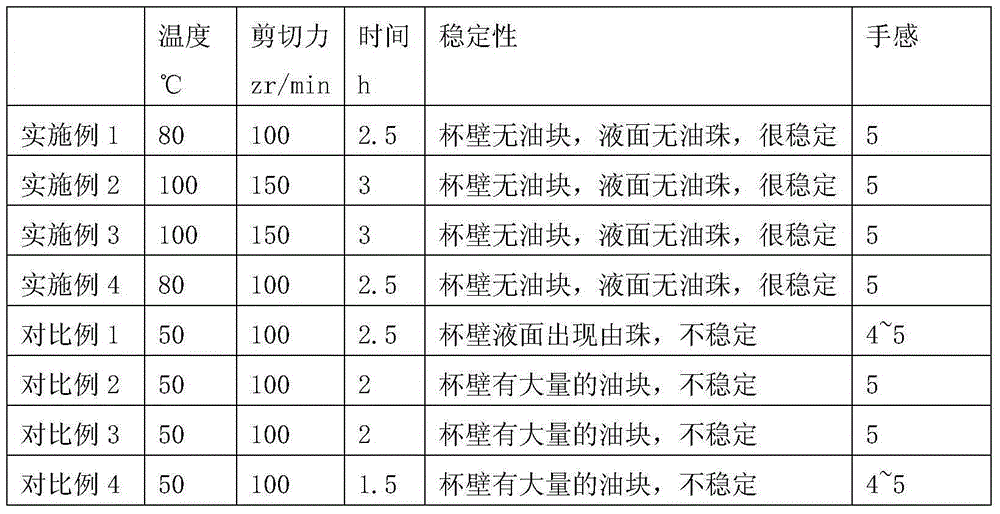

Embodiment 1

[0022] Preparation of Polydimethylsiloxane Oligomer Containing Si-H Group with a Viscosity of 4000mPa·s

[0023] 20 parts by weight of trimethoxysilane and 1 part of trifluoromethanesulfonic acid were added dropwise to 20 parts of deionized water within 20 minutes while stirring at room temperature, heated to reflux for 2 hours, cooled to room temperature, and washed with toluene and water , Distilled under reduced pressure at 60°C to obtain Si-H group-containing polydimethylsiloxane oligomers with a viscosity of 4000mPa·s.

[0024] The weight ratio of coupling agent I: coupling agent II is 5:1.

[0025] The softener is AE09 and TX-7, the weight ratio is 2:1. The HLB value is 5.

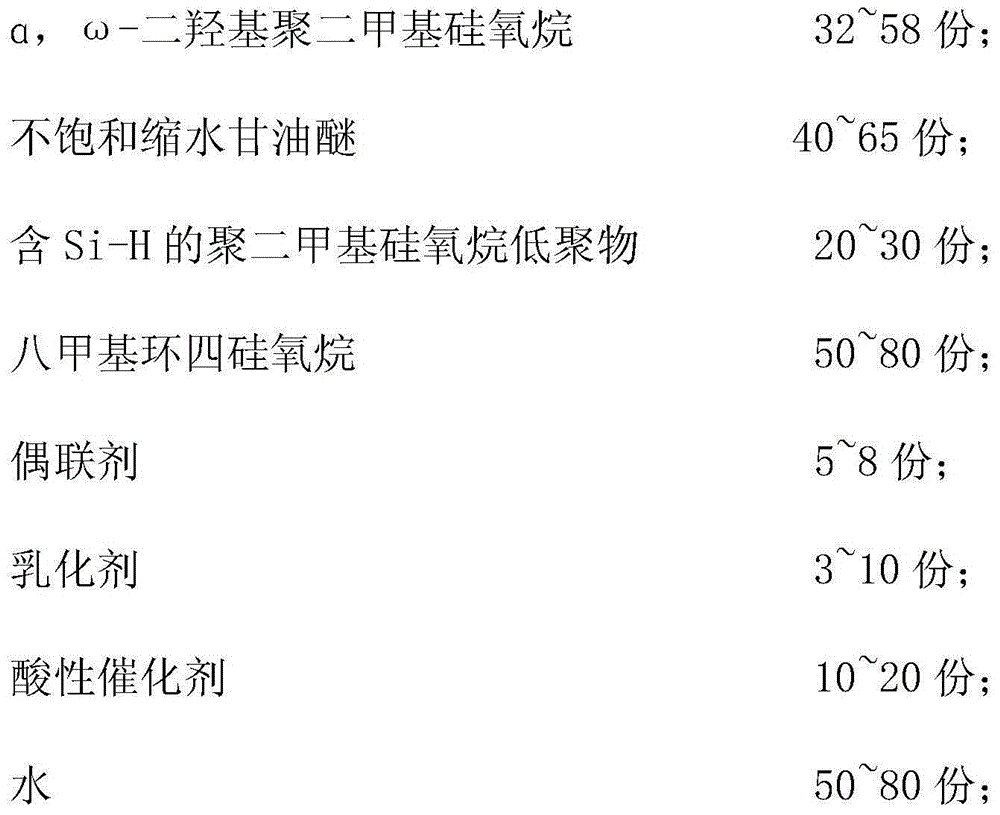

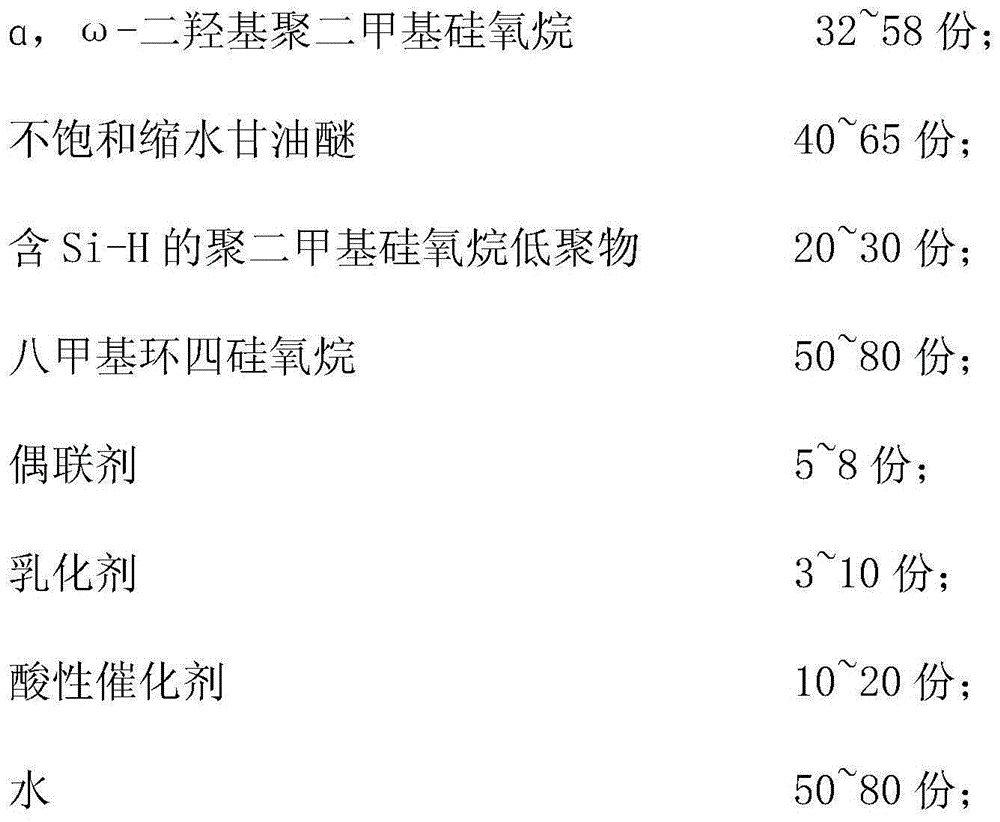

[0026] The formula of other components is: 40 parts of ɑ, ω-dihydroxy polydimethylsiloxane; 50 parts of phenyl glycidyl ether; 25 parts of polydimethylsiloxane oligomer containing Si-H; 65 parts of cyclotetrasiloxane; 6 parts of coupling agent; 6 parts of emulsifier; 15 parts of glacial acetic aci...

Embodiment 2

[0028] Preparation of Polydimethylsiloxane Oligomer Containing Si-H Group with a Viscosity of 5000mPa·s

[0029] 25 parts by weight of trimethoxysilane and 1.3 parts of trifluoromethanesulfonic acid were added dropwise to 20 parts of deionized water within 28 minutes while stirring at room temperature, heated to reflux for 2 hours, cooled to room temperature, and washed with toluene and water Distilled under reduced pressure at 75°C to obtain Si-H group-containing polydimethylsiloxane oligomers with a viscosity of 5000 mPa·s.

[0030] The weight ratio of coupling agent I: coupling agent II is 8:1.

[0031] The softener is AE09 and TX-7, the weight ratio is 1:1, and the HLB value is 10.

[0032] The formula of other components is: 58 parts of ɑ, ω-dihydroxy polydimethylsiloxane; 65 parts of phenyl glycidyl ether; 30 parts of polydimethylsiloxane oligomer containing Si-H; 80 parts of cyclotetrasiloxane; 8 parts of coupling agent; 10 parts of emulsifier; 20 parts of glacial ace...

Embodiment 3

[0034] Preparation of Polydimethylsiloxane Oligomer Containing Si-H Group with a Viscosity of 6000mPa·s

[0035] 30 parts by weight of trimethoxysilane and 1.6 parts of trifluoromethanesulfonic acid were added dropwise to 18 parts of deionized water within 28 minutes while stirring at room temperature, heated to reflux for 8 hours, cooled to room temperature, and washed with toluene and water , Distilled under reduced pressure at 76°C to obtain polydimethylsiloxane oligomers containing Si-H groups with a viscosity of 6000mPa·s.

[0036] The weight ratio of coupling agent I: coupling agent II is 5:1.

[0037] The softener is AE09 and TX-7, the weight ratio is 1:2, and the HLB value is 15.

[0038] Other component formulas are: ɑ, ω-dihydroxy polydimethylsiloxane 32 parts; phenyl glycidyl ether 40 parts; Si-H containing polydimethylsiloxane oligomer 20 parts; 50 parts of cyclotetrasiloxane; 5 parts of coupling agent; 3 parts of emulsifier; 10 parts of glacial acetic acid, 50 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com