Method for preparing energetic hollow microspheres by microwave heating method

A technology of microwave heating and microspheres, which is applied in the preparation of energetic hollow microspheres and the field of microwave heating to prepare energetic hollow microspheres, which can solve the problem of cracking, uneven heating of energetic hollow microspheres, and different particle sizes of microspheres to prevent demulsification, solve the contradiction between high power and high sensitivity, and improve storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

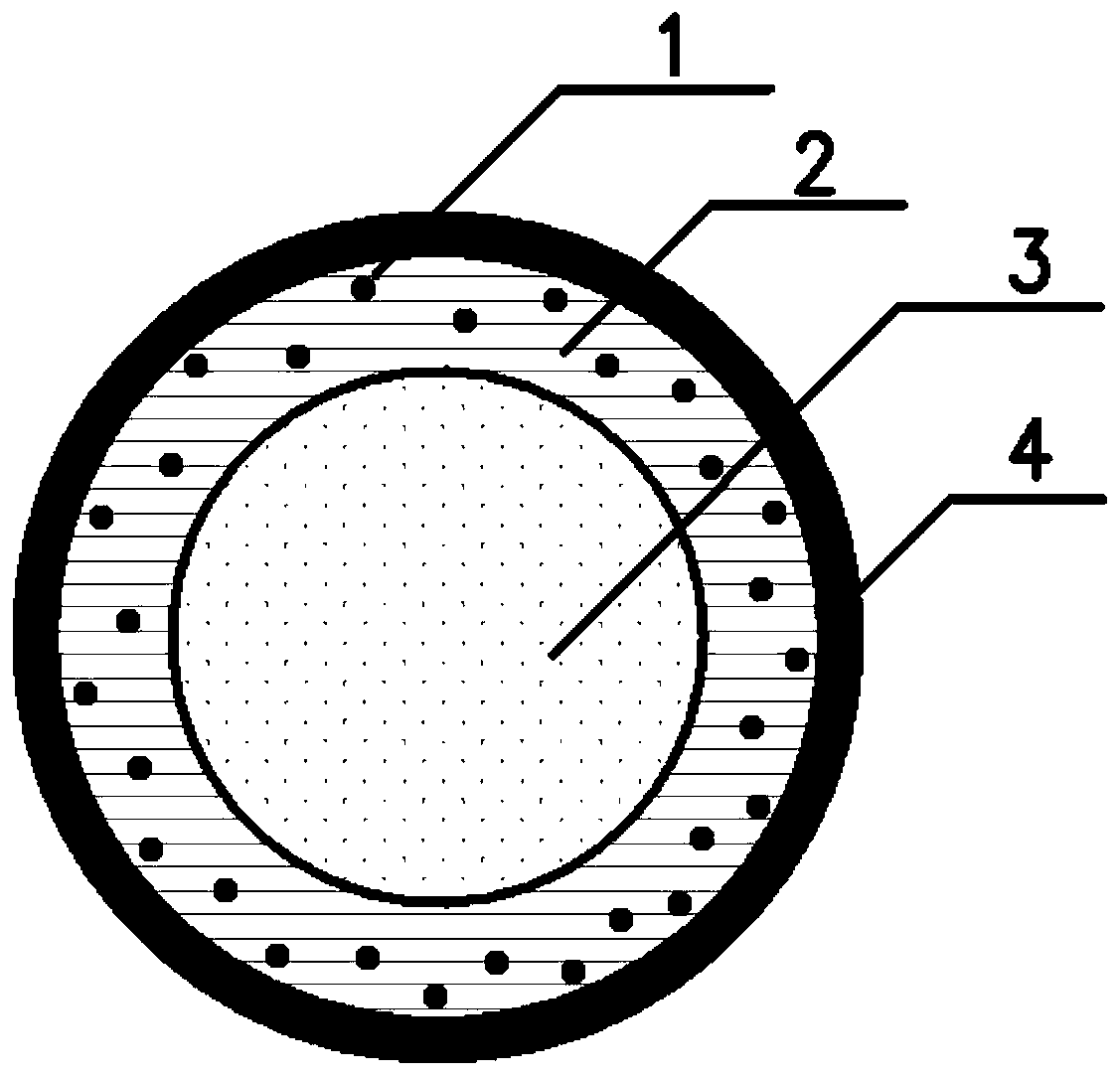

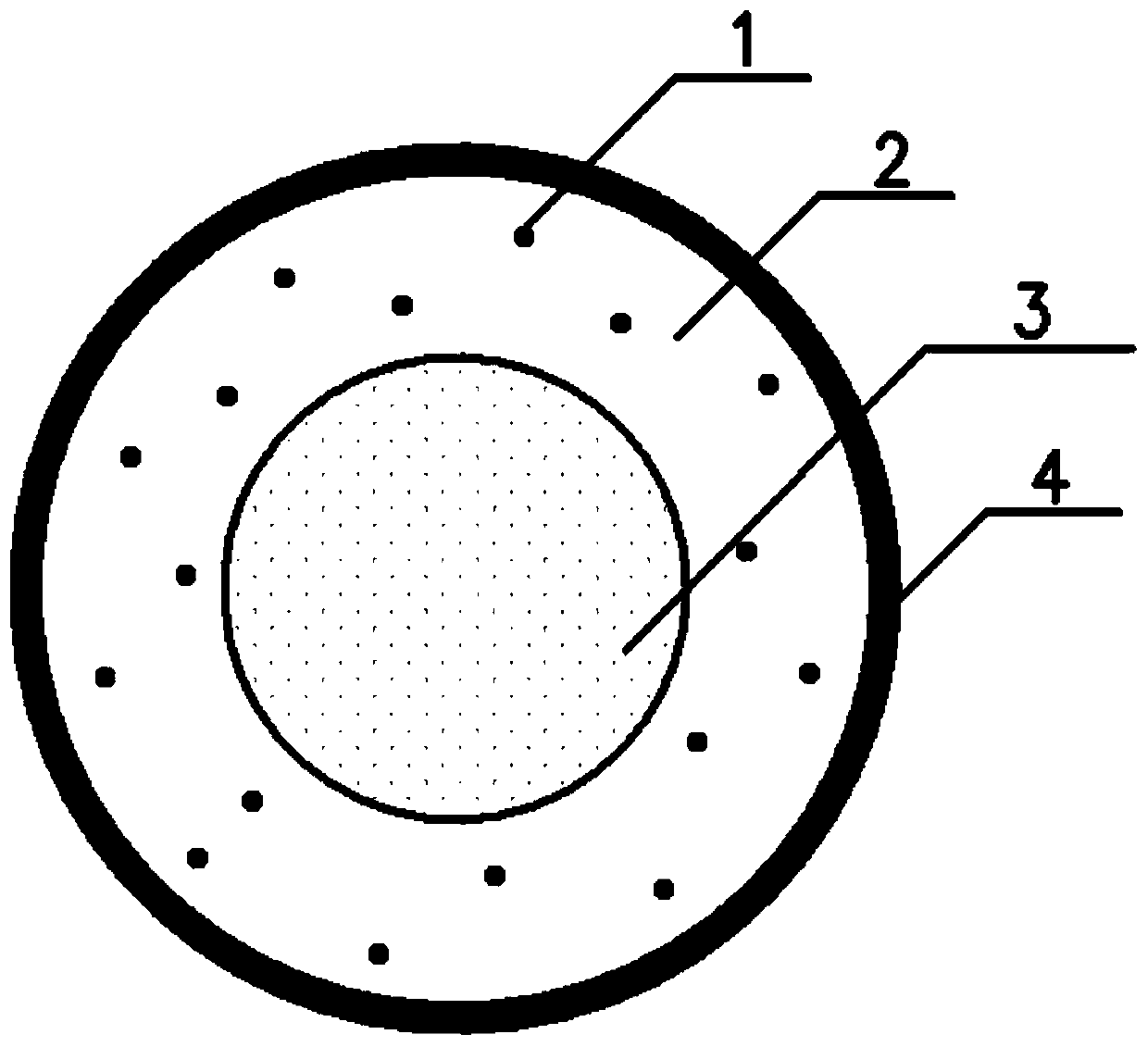

[0031] Ti H 2 The preparation method of type energetic hollow microspheres: the energetic hollow microspheres are mainly composed of the following components in parts by weight: 5 parts of wave-absorbing material polyaniline, 10 parts of expansion agent p-toluenesulfonyl hydrazide, energetic additive TiH 2 65 parts of powder, 20 parts of acrylate monomer.

[0032] The TiH 2 The preparation method of type energy-containing hollow microspheres, the specific steps are as follows:

[0033] St1: First mix and dissolve 20 parts of acrylate monomer, 1 part of initiator azobisisobutyronitrile, 0.1 part of crosslinking agent polyethylene glycol (200 / 400) dimethacrylate, 10 parts of expansion agent p-toluene Sulfonyl hydrazide forms the oil phase, and then 65 parts of energetic additive TiH with an average particle size of 15 μm are added 2 Powder and 5 parts of wave-absorbing material polyaniline and stir well to make it evenly mixed with the oil phase;

[0034] St2: In 91 parts of...

Embodiment 2

[0038] The preparation method of Al powder-type energetic hollow microspheres: the energetic hollow microspheres are mainly composed of the following components in parts by weight: 4 parts of wave-absorbing material polythiophene, 11 parts of expansion agent dichloromethane, and energetic additive Al 70 parts of powder, 15 parts of fluorine-containing acrylate monomer.

[0039] The preparation method of the Al powder type energetic hollow microspheres, the specific steps are as follows:

[0040] St1: First mix and dissolve 15 parts of fluorine-containing acrylate monomer, 1.5 parts of initiator tertiary amine, 0.2 parts of crosslinking agent dicumyl peroxide, 11 parts of expansion agent dichloromethane, and then add 70 parts of average particle size 32μm The energy-containing additive Al powder and 4 parts of wave-absorbing material polythiophene are fully stirred to make them evenly mixed with the oil phase;

[0041] St2: In 95 parts of deionized water, add 4 parts of disper...

Embodiment 3

[0045] The preparation method of Mg powder-type energetic hollow microspheres with different expansion ratios: the energetic hollow microspheres are mainly composed of the following components in parts by weight: 8 parts of polyacetylene as a wave-absorbing material, 12 parts of expansion agent isodecane, 65 parts of energetic additive Mg powder, 15 parts of acrylamide monomer.

[0046] The preparation method of the Mg powder type energetic hollow microspheres, the specific steps are as follows:

[0047] St1: First mix and dissolve 15 parts of acrylamide monomer, 0.8 parts of initiator mercaptan, 0.3 parts of crosslinking agent trimethylolpropane trimethacrylate, 12 parts of expansion agent isodecane, and then add 65 parts of average particle size Energetic additive Mg powder with a diameter of 28 μm and 8 parts of wave-absorbing material polyacetylene are stirred thoroughly to make them evenly mixed with the oil phase;

[0048] St2: In 92 parts of deionized water, add 7.5 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com