Instant emusifying burner using fuel oil/light oil

A combustion device and fuel oil technology, applied in the direction of burners, lighting and heating equipment, etc., can solve the problems of blackened exhaust smoke, failure to achieve fuel saving, and inability to achieve fuel saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

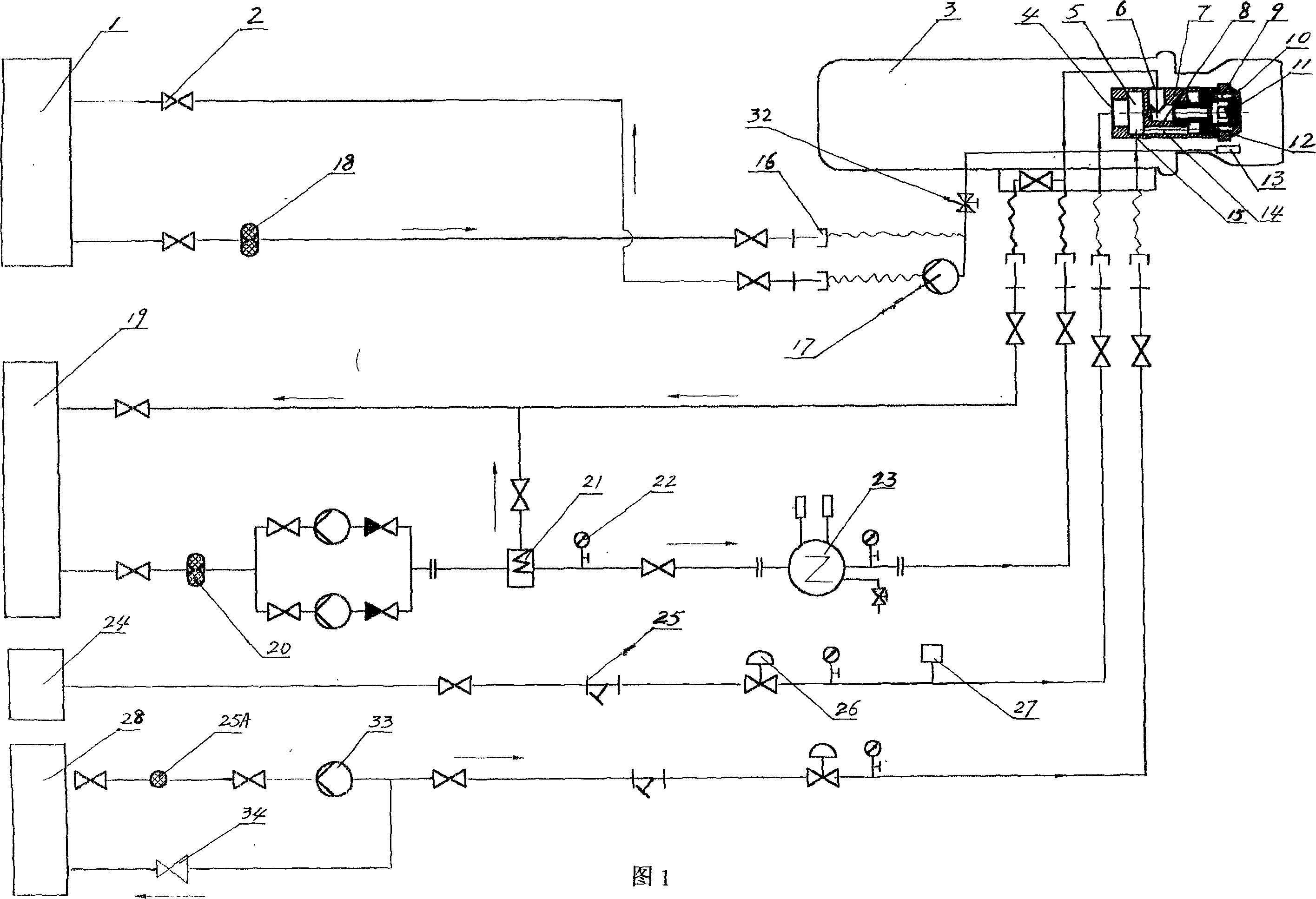

[0016] As shown in FIG. 1 , the instant fuel oil / light oil emulsification combustion device of the present invention includes a burner 3 , a light oil tank 1 , a heavy oil storage tank 19 , a steam source 24 and a water tank 28 . There are emulsification nozzles and light oil ignition nozzles 13 in the burner 3, and these two nozzles are arranged side by side, and their fuel injection ports face the same direction.

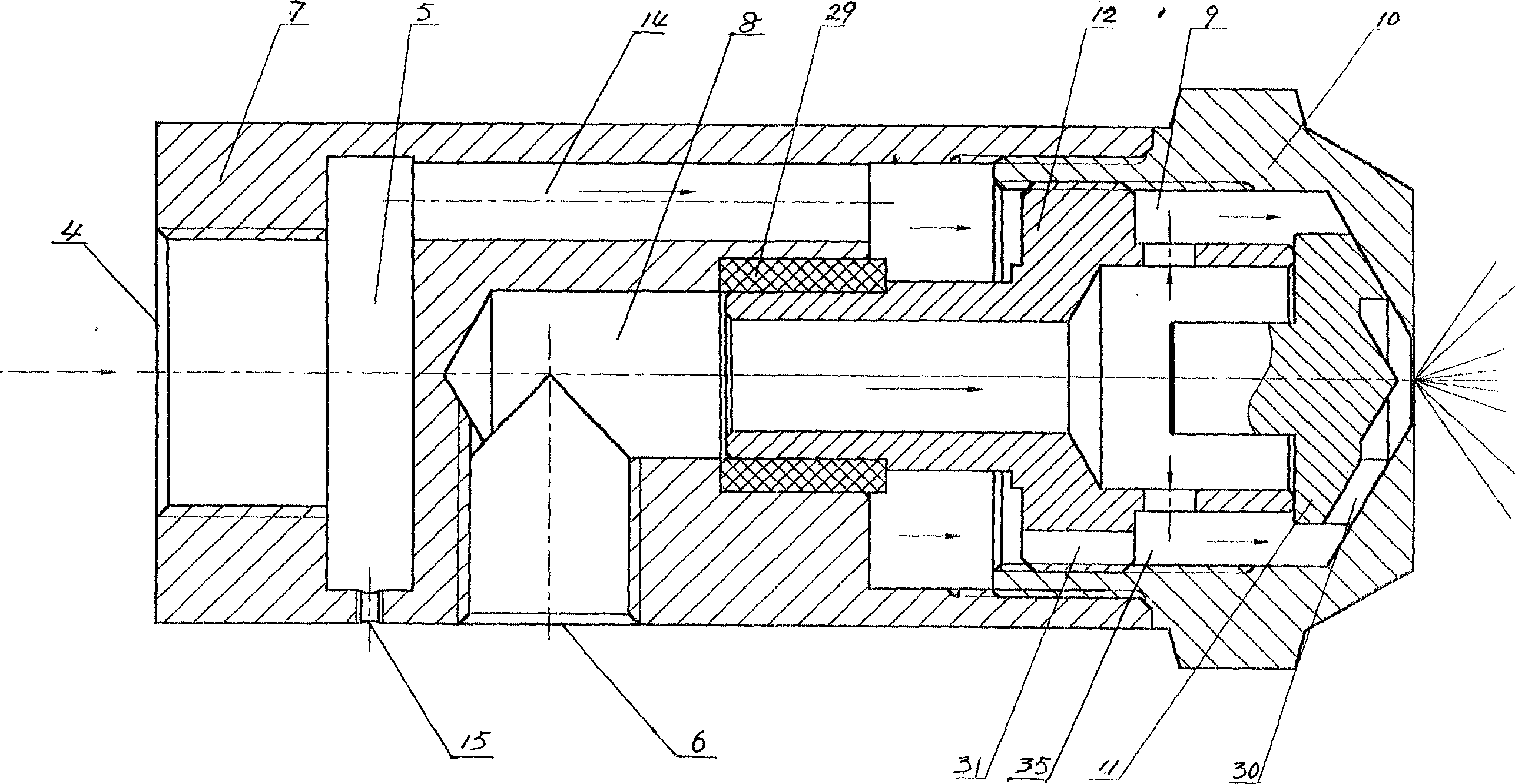

[0017] See figure 2 , said emulsifying nozzle comprises oil head body 7, and this oil head body is cylindrical, and its rear end center is processed with longitudinal big blind hole. The mouth of the longitudinal large blind hole is an atomized steam inlet 4, and its inner section has a diameter larger than its outer section, so that a steam-water mixing chamber 5 is formed in its inner section. The center of the front end of the oil head body 7 is processed with a blind hole, and the diameter of the inner section of the blind hole is smaller than that of the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com