Preparation method of superhydrophobic dielectric material and dielectric material prepared by method

A technology of dielectric materials and dielectric materials, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve problems such as not considering the influence of surface roughness, so as to avoid excessive etching rate, Avoid excessive changes and reduce the effect of process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

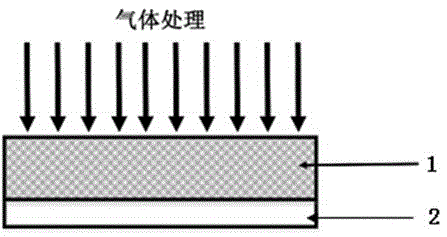

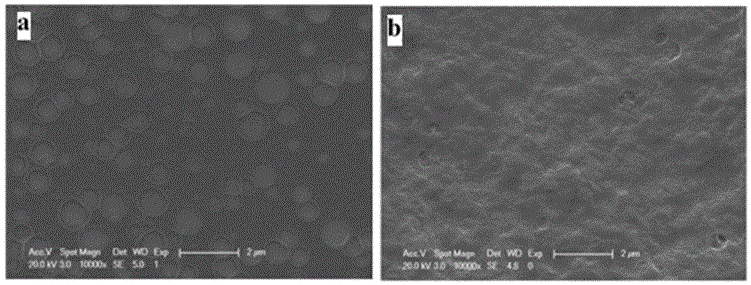

[0027] like figure 1 As shown, the present invention provides a treatment method applied to the superhydrophobic medium material of the dielectric electrowetting digital microfluidic chip. %; Lactic acid-glycolic acid copolymer is dissolved in dimethylformamide, the mass ratio of the two is 10%, and the two solutions are mixed at a volume ratio of 4:1. The mixed solution 1 of cellulose triacetate and lactic acid-glycolic acid copolymer can form a film on the surface of the substrate 2 (such as ITO glass, silicon wafer) by the method of spin coating, and then pass through two kinds of gas sources (CF 4 with CHF 3 ) reactive ion etching, carbon tetrafluoride (CF 4 ) during the treatment of the reaction gas source, the power is 100W~50W, the gas flow rate is 30sccm~10sccm; trifluoromethane (CHF 3 ) During the processing of the reaction gas source, the power is 50W, and the gas flow rate is 20 sccm (standard-state cubic centimeter per minute, standard-state milliliters per minu...

Embodiment 2

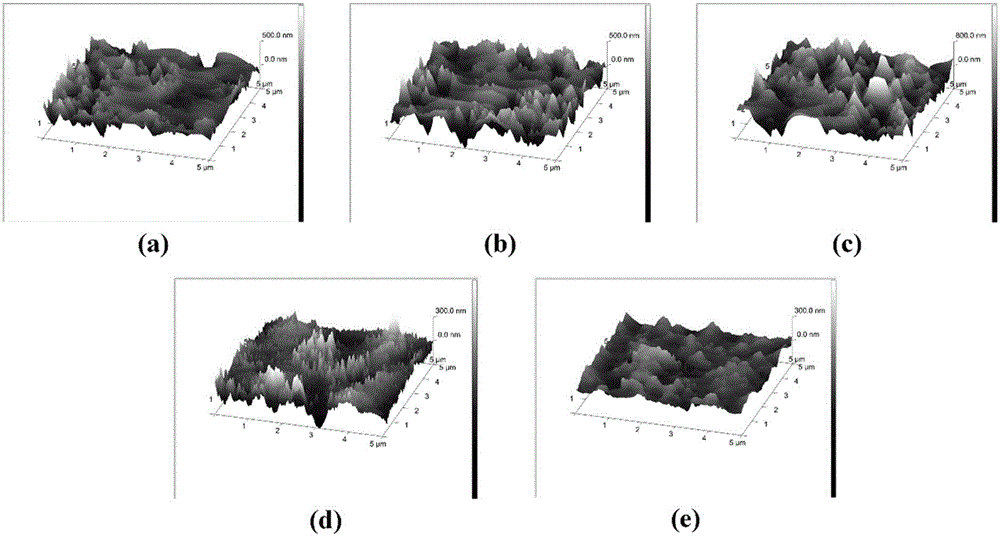

[0032] In this example, carbon tetrafluoride (CF 4 ) gradually reduce the power and reaction gas volume during the treatment of the reaction gas source. The specific performance is: firstly, the power is 100W, the flow rate is 30sccm, the time is 3min30s, and the surface roughness increases by 1.24 times. image 3 As shown in (a); Then, the power is 50W, the flow rate is 30sccm, and the time is 3min30s, the surface roughness increases by 0.27 times, as image 3As shown in (b); the power is 50W, the flow rate is 10sccm, the time is 7min30s, and the surface roughness increases by 0.68 times, such as image 3 (c) in; finally, trifluoromethane (CHF 3 ) Reaction gas source treatment (keep the power and reaction gas volume unchanged): power is 50W, flow rate is 20sccm, time is 7min30s, surface roughness is reduced by 0.68 times, such as image 3 In (d) shown.

[0033] In the present invention, the increase or decrease of surface roughness is represented by the ratio relative to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com