Trifluoromethanesulfonic acid preparation method

A kind of technology of trifluoromethanesulfonic acid and sodium trifluoromethanesulfonate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

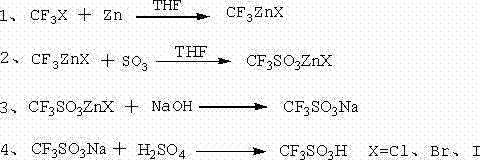

[0025] The preparation method of trifluoromethanesulfonic acid of the present invention comprises the following steps:

[0026] 1. Preparation of trifluoromethyl zinc halide: under the protection of nitrogen, mix zinc powder with tetrahydrofuran solvent at room temperature, and after obtaining the suspension, feed part of trifluorohalomethane gas, add a catalytic amount of elemental iodine as a catalyst, and heat slowly When the temperature rises to 40°C, after the reaction starts, slowly feed the remaining halotrifluoromethane gas, control the temperature below 50°C and stir for 5 hours to obtain the trifluoromethylzinc halide reaction solution.

[0027] 2. Preparation of zinc halide trifluoromethanesulfonate: adding solid sulfur trioxide to the prepared zinc trifluoromethanesulfonate halide reaction liquid, stirring and reacting for 2.0 h to obtain zinc halide trifluoromethanesulfonate reaction liquid.

[0028] 3. Preparation of sodium trifluoromethanesulfonate: In the prepa...

Embodiment 1

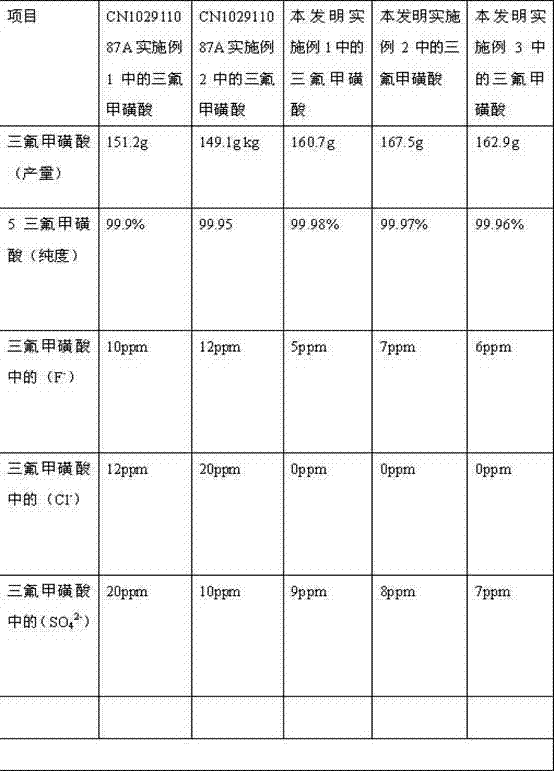

[0031] Under the protection of nitrogen, 66g of trifluorochloromethane liquid was passed into 1L tetrahydrofuran suspension of 212g of zinc powder, and then a catalytic amount of elemental iodine was added, and slowly heated to 40°C. After the reaction should occur, slowly passed into 198g of trifluoromethane Fluorochloromethane, control the temperature not to exceed 50°C. After stirring and reacting for 5 hours, slowly add 260 g of solid sulfur trioxide, and stir and react for 2 hours after feeding is completed. The reaction solution was neutralized with 30% aqueous sodium hydroxide solution, and when no precipitation occurred, the solid was filtered off, and the filtrate was evaporated and dried to obtain sodium trifluoromethanesulfonate as a solid. Mix and stir the sodium salt and 240g of concentrated sulfuric acid, react at 100°C for 5h, and rectify to obtain 160.7g of trifluoromethanesulfonic acid. (Content: 99.98%; F - :5ppm; Cl - : 0ppm; SO 4 2- :9ppm)

Embodiment 2

[0033] Under the protection of nitrogen, 100 g of bromotrifluoromethane liquid was passed into 1 L of tetrahydrofuran suspension of 212 g of zinc powder, and then a catalytic amount of elemental iodine was added, and slowly heated to 40 ° C. After the reaction should start, 300 g of trifluoromethane was slowly passed into For methyl bromide, the temperature should not exceed 50°C. After stirring and reacting for 5 hours, slowly add 260 g of solid sulfur trioxide, and stir and react for 2 hours after feeding is completed. The reaction solution was neutralized with 30% aqueous sodium hydroxide solution, and when no precipitation occurred, the solid was filtered off, and the filtrate was evaporated and dried to obtain sodium trifluoromethanesulfonate as a solid. Mix and stir the sodium salt and 240g of concentrated sulfuric acid, react at 100°C for 5h, and rectify to obtain 167.5g of trifluoromethanesulfonic acid. (Content: 99.97%; F - : 7ppm; Cl - : 0ppm; SO 4 2- :8ppm)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com