Mixed working medium for organic working medium rankine cycle system of screw expander

A technology of screw expander and mixed working medium, which is applied in the field of heat pump circulating working medium and refrigeration, which can solve the problems of high risk, flammability and explosion, etc., and achieve improved heat transfer, high cycle heat utilization rate and excellent cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

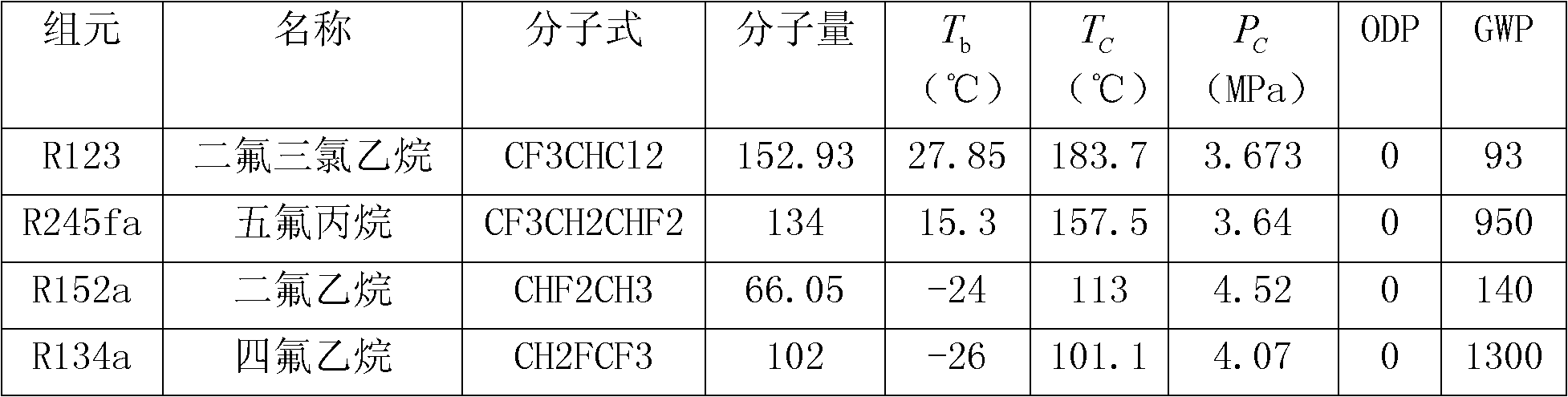

[0039] The preparation method of the above-mentioned mixed working medium is to physically mix the component substances according to the set mass ratio at normal temperature.

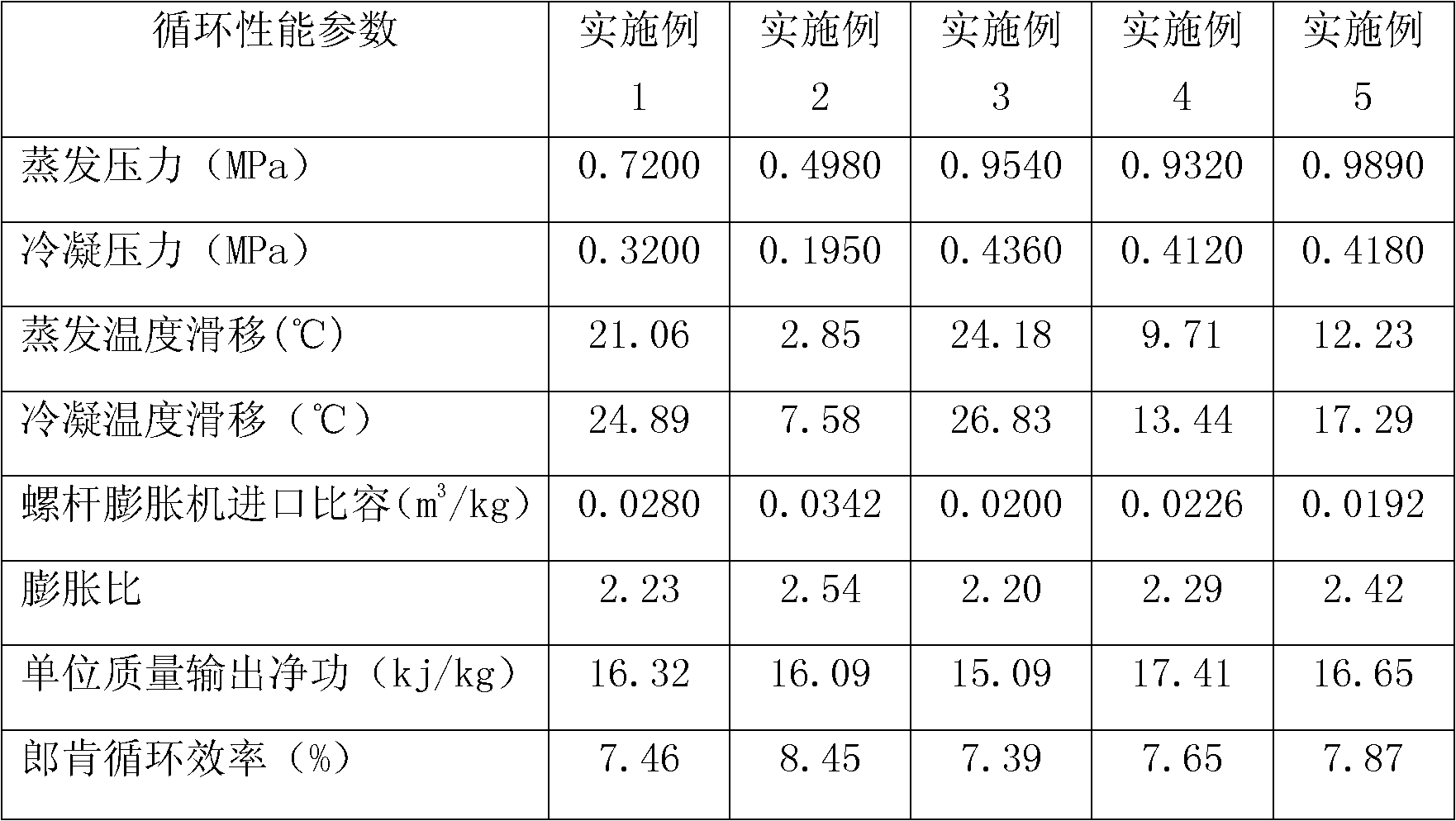

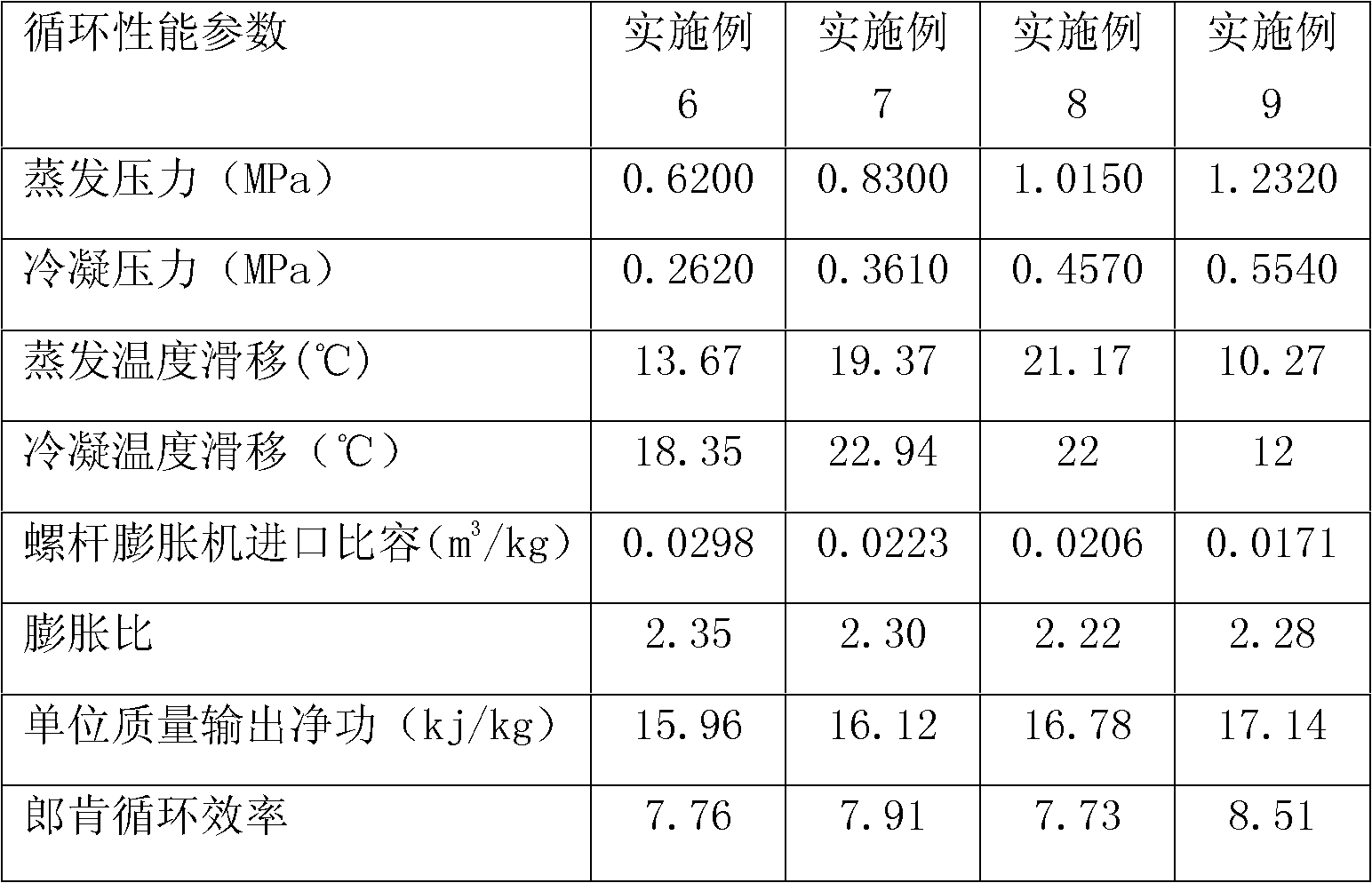

[0040] Specific examples are as follows:

example 1

[0042] Take 82.5% HCFC-123 and 17.5% HFC-152a, mix them physically at room temperature and use them as circulating working fluid.

example 2

[0044] 65.5% HCFC-123 and 34.5% HFC-245fa are used as circulating working fluid after physical mixing at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com