Multi-element mixed refrigerant suitable for cryogenic regions of -130 to -180 DEG C

A mixed refrigerant and multi-component technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of mixed refrigerants such as poor low-temperature oil solubility, environmental protection characteristics, and increased system complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

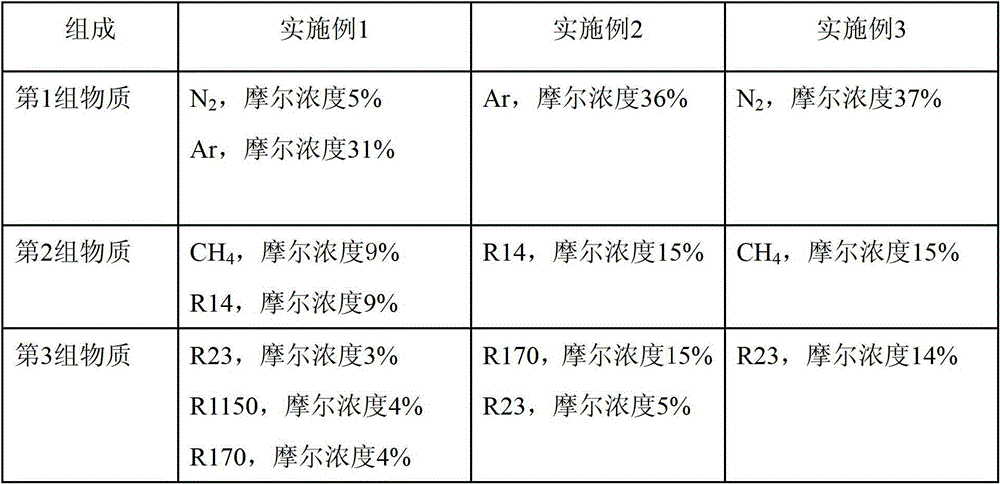

[0031] Prepare the completely non-flammable or only weakly flammable multi-component mixed refrigerant that operates in the temperature range of -130°C. The minimum heat transfer temperature difference inside the heat exchanger is 1K, the ambient temperature is 35 °C, and the working medium concentration of the multi-component mixed refrigerant is And the performance is shown in the table below:

[0032]

[0033]

Embodiment 4-6

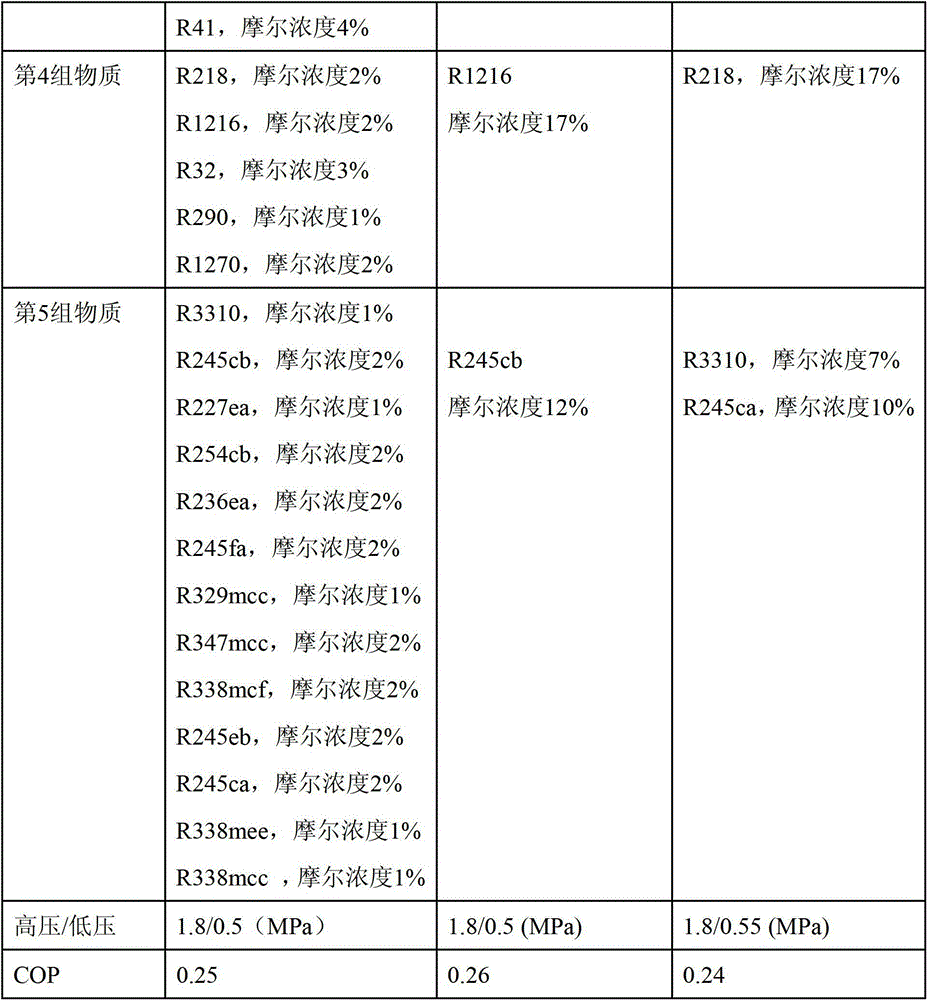

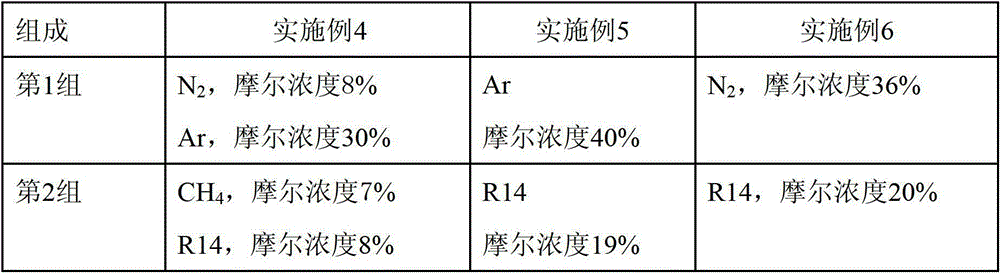

[0034] Example 4-6: Preparation of completely non-flammable or only weakly flammable multi-component mixed refrigerants operating in the temperature range of -150 ° C, the minimum heat transfer temperature difference inside the heat exchanger is 1K, and the ambient temperature is 35 ° C, and its multi-component mixed refrigeration See the following table for the working substance concentration and performance:

[0035]

[0036]

Embodiment 7-9

[0037] Example 7-9: Preparation of completely non-flammable or only weakly flammable multi-component mixed refrigerants operating in the temperature range of -180°C, the minimum heat transfer temperature difference inside the heat exchanger is 1K, and the ambient temperature is 35 °C, and its multi-component mixed refrigeration See the following table for the working substance concentration and performance:

[0038]

[0039]

[0040] In the above embodiments, the regenerative refrigeration system with completely non-flammable or only weakly flammable mixed refrigerants can safely and efficiently realize cooling in the temperature range of -130 to -180°C, which is comparable to the existing cryogenic mixed refrigerants. Compared with it, it is completely non-flammable or only weakly flammable, and has a low overall greenhouse effect and no ozone-depleting effect at all, which has significant advantages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com