Multi-element mixed working substance adapted to double temperature preparation of single-unit vapor compression type refrigerator

A technology for vapor compression and refrigeration equipment, which is applied in the fields of heat exchange materials, chemical instruments and methods, and can solve problems such as patent reports that have not yet been found.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

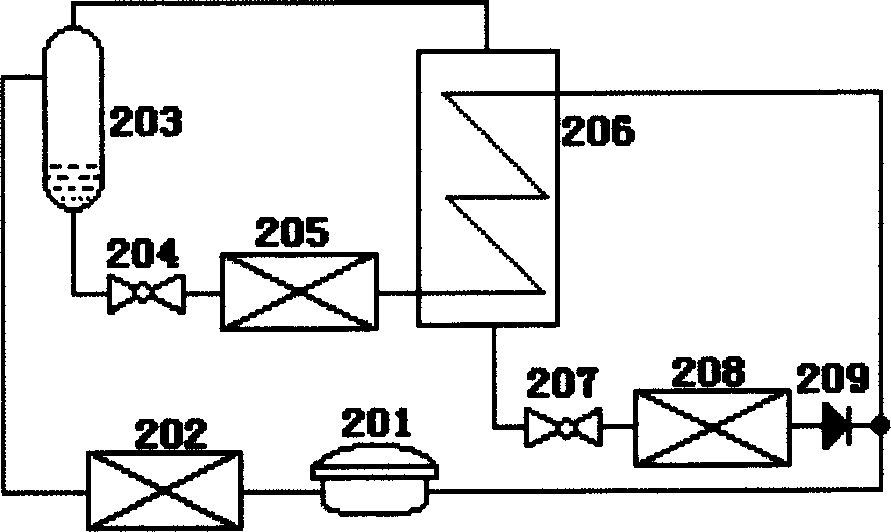

[0033] The ambient temperature is 25°C, the temperature of the low-temperature compartment of the dual-temperature refrigerator is -60°C to -50°C, and the temperature of the high-temperature compartment is -25°C to -15°C, and the cooling capacity of the low-temperature compartment and the high-temperature compartment are the same. Mixed working fluid; its refrigeration cycle is shown in Figure 201. The mass concentration and performance of the mixed working fluid are shown in Table 1, where w represents the compression work consumed per unit mass of the mixed working fluid, and q indicates that the unit mass of the mixed working fluid is between high and low temperature compartments Cooling capacity provided:

[0034] project

Embodiment 2

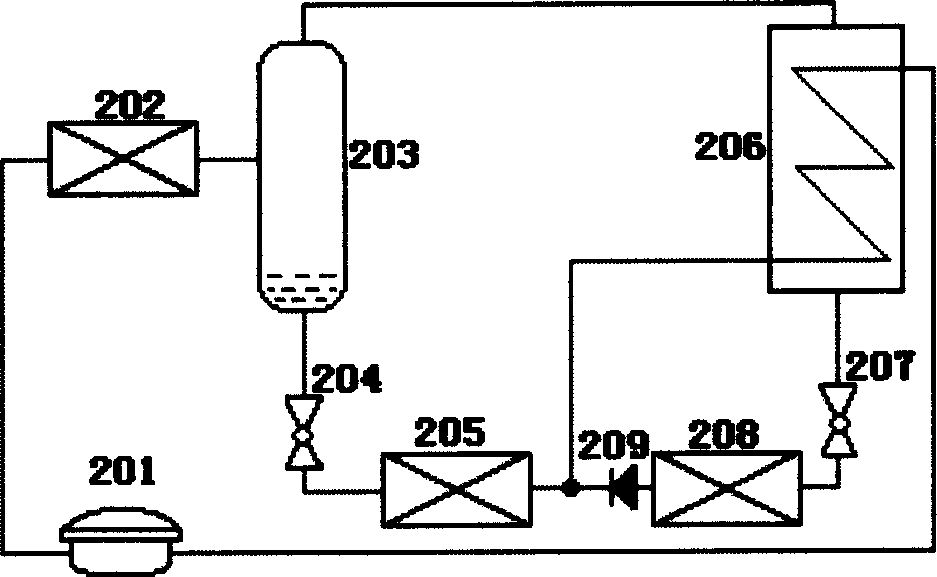

[0036]The ambient temperature is 25°C, the temperature of the low-temperature compartment of the dual-temperature refrigerator is -50°C to -40°C, and the temperature of the high-temperature compartment is -25°C to -15°C. The cooling capacity of the low-temperature compartment and the high-temperature compartment are the same. Mixed working fluid; its refrigeration cycle is shown in Figure 202. The mass concentration and performance of the mixed working fluid are shown in Table 2, where w represents the compression work consumed per unit mass of the mixed working fluid, and q indicates that the unit mass of the mixed working fluid is a high and low temperature compartment The amount of cooling provided.

[0037] project

Embodiment 3

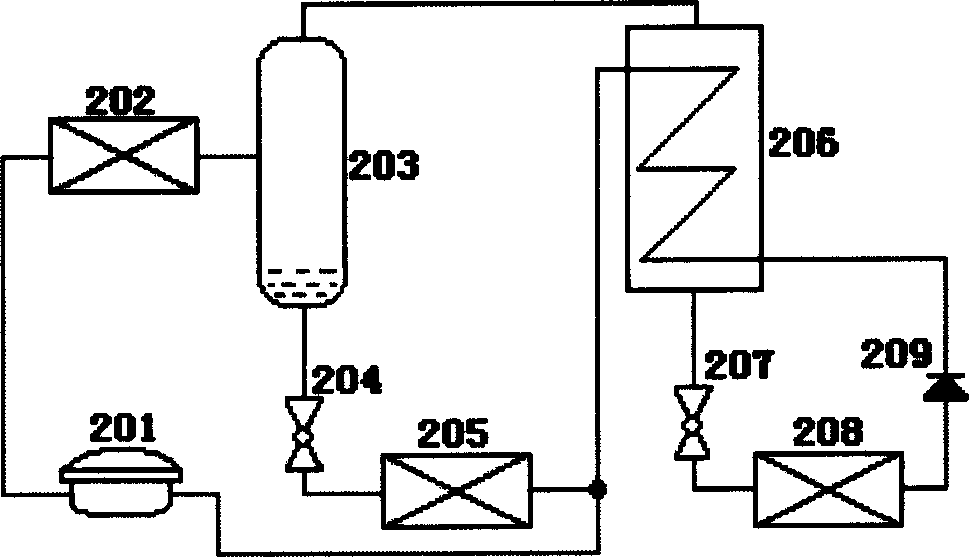

[0039] The ambient temperature is 25°C, the temperature of the low-temperature compartment of the dual-temperature refrigerator is -60°C to -50°C, and the temperature of the high-temperature compartment is -15°C to -5°C. The cooling capacity of the low-temperature compartment and the high-temperature compartment are the same. Mixed working fluid; its refrigeration cycle is shown in Figure 203. The mass concentration and performance of the mixed working fluid are shown in Table 3, where w represents the compression work consumed per unit mass of the mixed working fluid, and q indicates that the unit mass of the mixed working fluid is between high and low temperature compartments The amount of cooling provided.

[0040] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com