Ion exchange resin and preparation method thereof

The technology of ion exchange resin and tetrafluoroethylene is applied in the field of ion exchange resin and its preparation, and can solve the problems of low reactivity rate of sulfonyl fluoride-based vinyl ether monomer, low polymer yield, high requirement of reaction conditions and the like, To achieve the effect of increasing hydrophilic properties, simple preparation method and improving moisturizing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

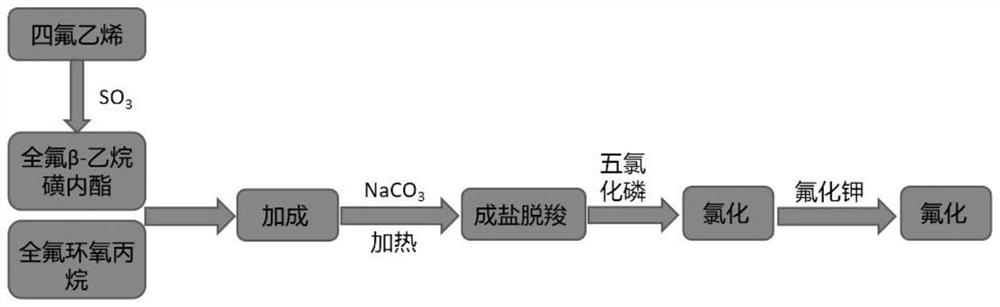

[0045] The embodiment of the present invention also provides a kind of preparation method of ion exchange resin, comprises the following steps:

[0046] a. Addition reaction of perfluoro β-ethane sultone or sulfonyl fluoride acetyl fluoride with perfluoropropylene oxide to obtain the addition product, whose molecular formula is FOC(CF(CF 3 )OCF 2 ) X CF 2 SO 2 F, where x is 1, 2 or 3;

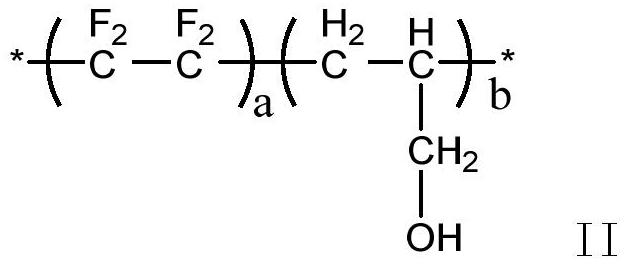

[0047] B, carry out copolymerization reaction with allyl alcohol monomer and tetrafluoroethylene monomer, make tetrafluoroethylene-allyl alcohol copolymer;

[0048] c. Carry out graft reaction between the tetrafluoroethylene-allyl alcohol copolymer prepared in step b and the addition product obtained in step a, and transform to obtain an ion exchange resin.

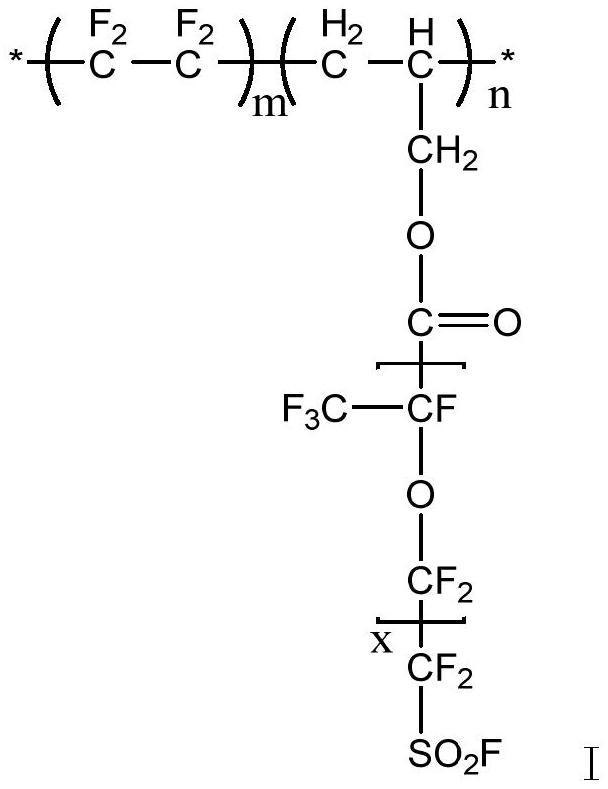

[0049] The reaction formula of the embodiment of the present invention is as follows, taking X=1 as an example:

[0050]

[0051] The preparation method of the ion exchange resin of the embodiment of the present invention is to po...

Embodiment 1

[0062] Dehumidify and deoxygenate the reactor, the oxygen content does not exceed 10ppm, the water content does not exceed 10ppm, quickly add dry diethylene glycol dimethyl ether, KF, perfluoro β-ethane sultone, stir evenly, and heat up to 30°C , slowly feed metered dry perfluoropropylene oxide, wherein the molar ratio of perfluoropropylene oxide to perfluoro β-ethane sultone is 1.2:1, keep the pressure at 0.2Mpa, react for 8 hours, and refine the product Distillation to obtain adduct product A.

[0063] Add 58g of allyl alcohol, 9g of azobisisobutyronitrile, 90g of butyl acetate, and 90g of methyl isobutyl ketone into the reaction kettle, stir evenly, vacuumize, and inject N 2 , then evacuate, feed tetrafluoroethylene to the reactor pressure of 2.0MPa, raise the temperature to 68°C, react for 14 hours, stop the reaction when the reactor pressure is between 0.8-1.0MPa, collect unreacted tetrafluoroethylene gas and olefin The propanol monomer is purified to obtain a tetrafluor...

Embodiment 2

[0068] Dehumidify and deoxygenate the reactor, the oxygen content does not exceed 10ppm, the water content does not exceed 10ppm, quickly add dry diethylene glycol dimethyl ether, KF, perfluoro β-ethane sultone, stir well, and heat up to 40°C , slowly feed metered dry hexafluoropropylene oxide, wherein the molar ratio of perfluoropropylene oxide to perfluoro β-ethane sultone is 1.3:1, keep the pressure at 0.3Mpa, react for 7 hours, and carry out rectification of the product , to obtain the one-time addition product A.

[0069] Add 87g of allyl alcohol, 9g of azobisisobutyronitrile, 90g of butyl acetate, and 90g of methyl isobutyl ketone into the reaction kettle, stir evenly, vacuumize, and introduce N 2 , then evacuate, feed tetrafluoroethylene to the reactor pressure of 2.0MPa, raise the temperature to 75°C, react for 16 hours, stop the reaction when the reactor pressure is between 0.9-1.0MPa, collect unreacted tetrafluoroethylene gas and alkene The propanol monomer is purif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com