Cleaning method of plasma processing apparatus and plasma processing method

a plasma processing apparatus and plasma technology, applied in the direction of cleaning processes and apparatus, chemistry apparatus and processes, electric discharge tubes, etc., can solve the problems of difficult radical action on the processing target substrate, process may not be performed efficiently, and the electrolytic structure of the electrodes would be largely damaged by the hydrogen plasma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Hereinafter, illustrative embodiments will be described in detail with reference to the accompanying drawings.

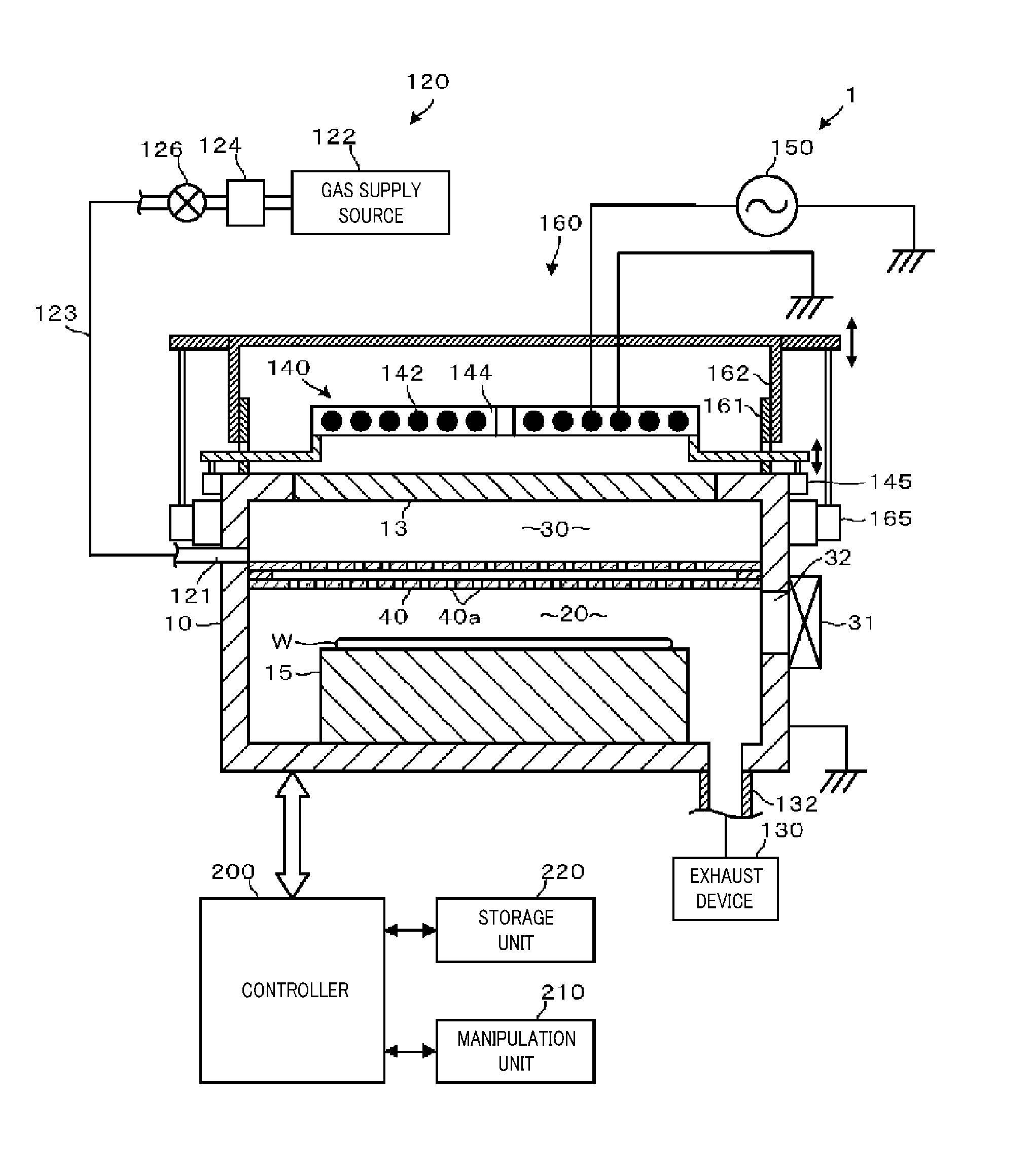

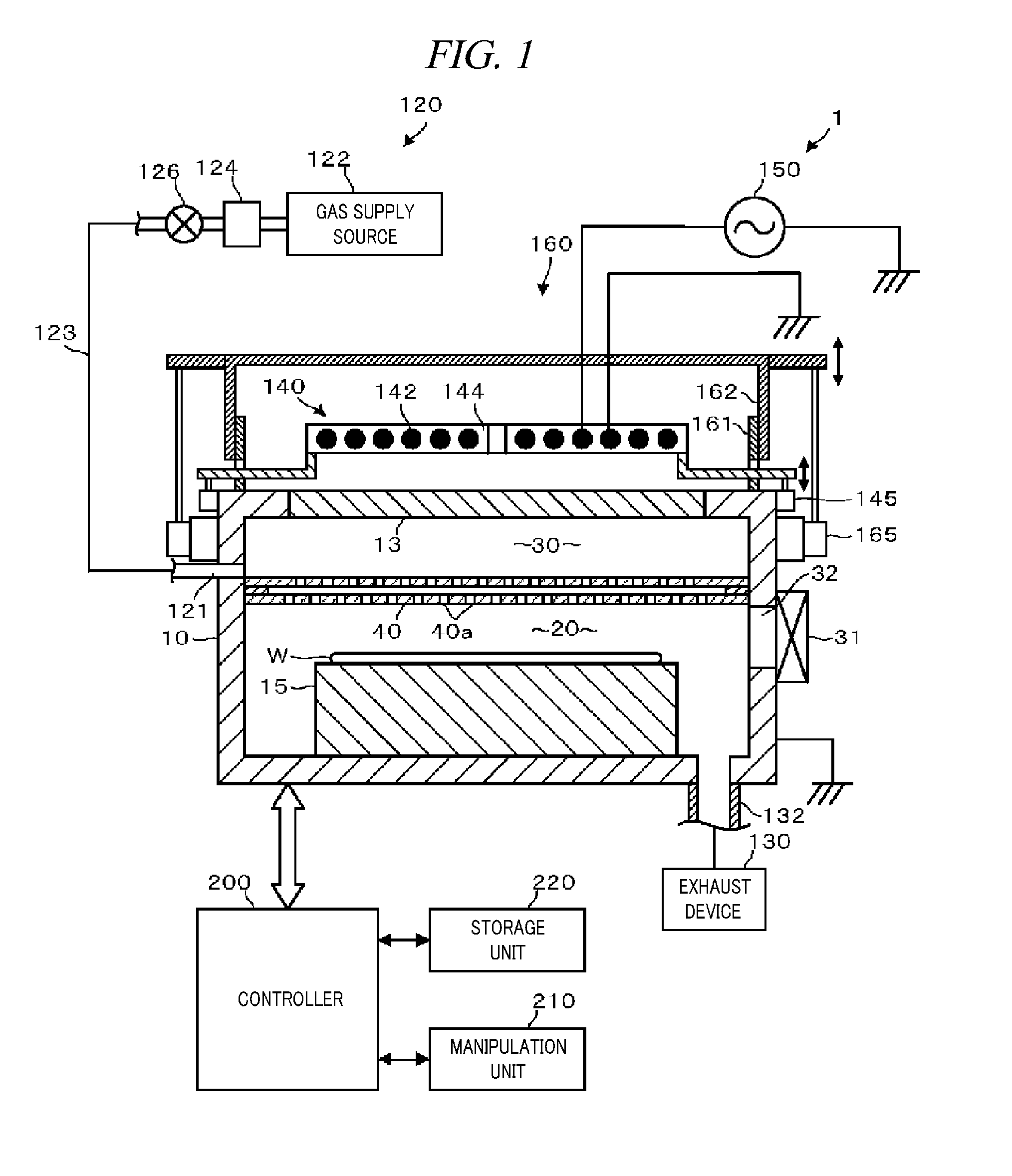

[0024]FIG. 1 schematically illustrates a configuration of a plasma processing apparatus 1 in accordance with an illustrative embodiment. The configuration of the plasma processing apparatus 1 will be first explained. The plasma processing apparatus 1 includes a processing chamber 10. The processing chamber 10 has a surface made of, but not limited to, an anodically oxidized aluminum and has a substantially cylindrical shape. A mounting table 15 for mounting thereon a processing target substrate such as a semiconductor wafer W is provided at a bottom portion within the processing chamber 10. A non-illustrated electrostatic chuck or the like for attracting and holding the processing target substrate is provided on a substrate mounting surface of the mounting table 15.

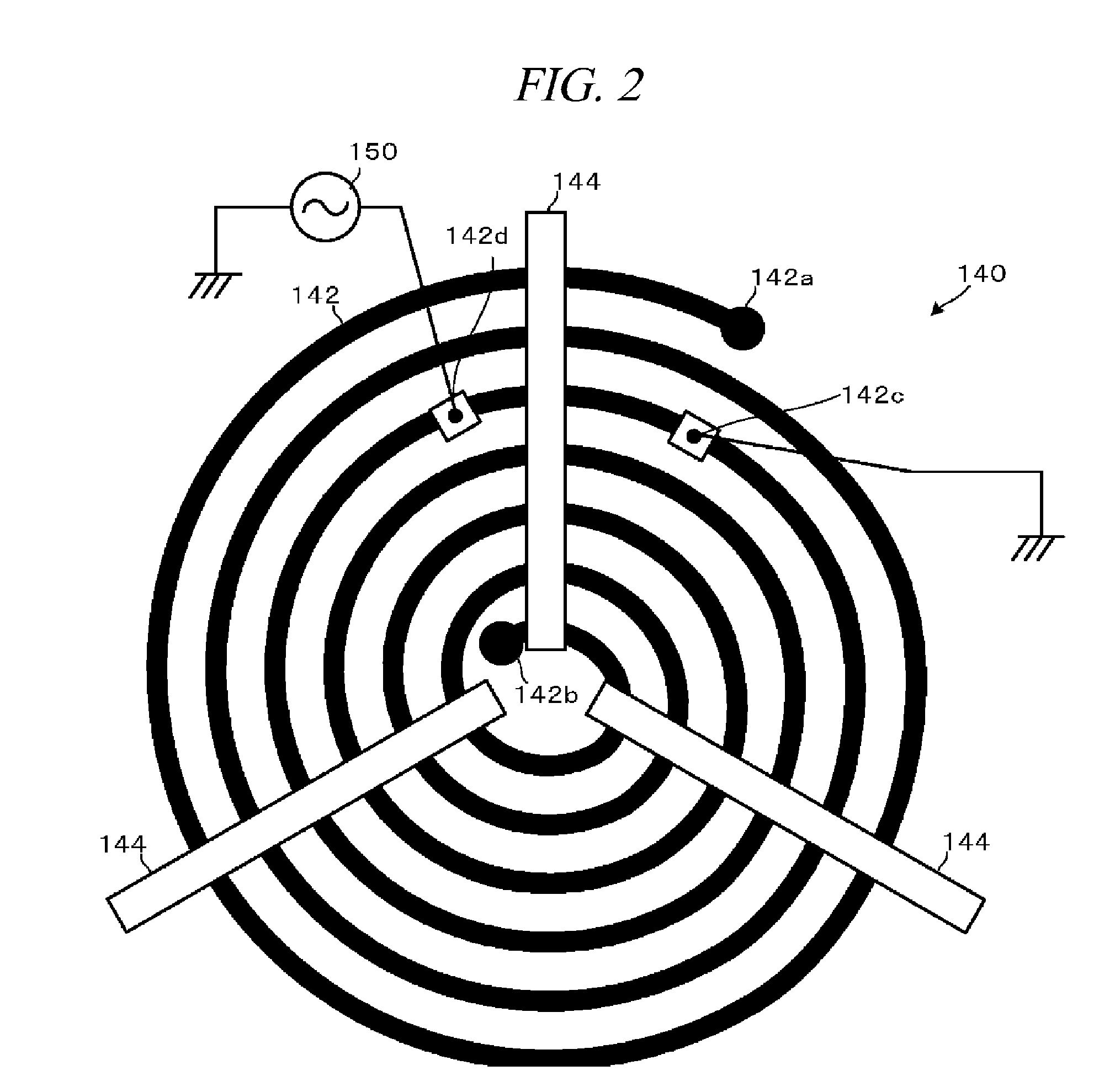

[0025]A dielectric window 13 made of quartz as a silicon-containing member is provided at a ceiling of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dielectric polarization enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com