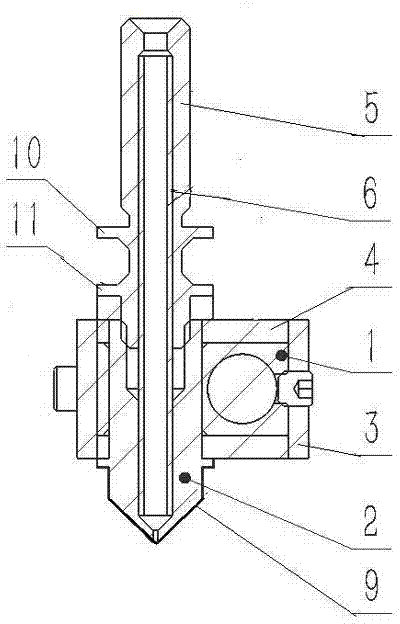

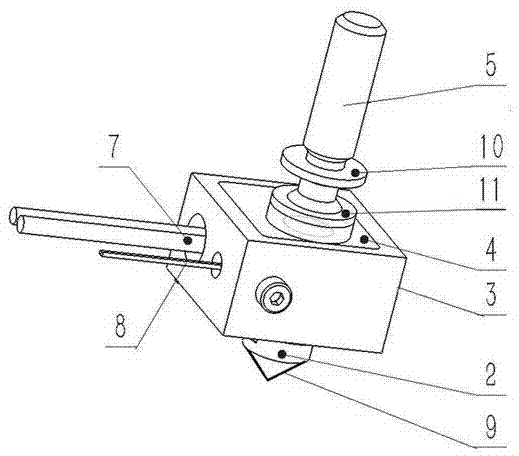

Extruding head of FDM 3D printer

An extrusion head and printer technology, applied in the field of FDM 3D printer extrusion head, can solve the problems of material leakage, easy loosening of high-temperature tape, oxidation of brass nozzles, etc., and achieve stable performance and good printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Referring to the accompanying drawings, a FDM 3D printer extrusion head of the present invention includes a heating block, a brass nozzle 2, a stainless steel throat pipe 5, a PTFE lining pipe 6, a single-head heating pipe 7, and a temperature sensor 8; it is characterized in that It also includes PTFE insulation shells 3, 4, the heating block is a brass heating block 1, and the brass heating block 1 is provided with a brass nozzle, a single-head heating tube 7, a temperature sensor 8 and a fastening bolt. Hole positions, PTFE insulation shells 3 and 4 are installed outside the brass heating block 1 and fixed with bolts; a layer of PTFE anti-sticking and anti-oxidation layer 9 is added to the outer surface of the brass nozzle 2, and a stainless steel throat pipe 5 is provided in the middle. The limit flange 10, the PTFE liner 6 extends to the inside of the brass nozzle 2, and runs through the inside of the stainless steel throat 5 of the limit flange 10 and the inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com