Catalyst for manufacturing olefin by low-carbon alkane dehydrogenation and application thereof

A technology of low-carbon alkanes and catalysts, which is applied in the production of basic organic chemical raw materials, can solve the problems of low conversion rate of raw materials, and achieve the effect of improving dispersion and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] First, SAPO-34 molecular sieve and alumina are mixed, granulated into spherical shape, the particle size ranges from 20 to 100 microns, and the mass ratio of SAPO-34 to alumina is 2.3; then the carrier is 0.16M SnCl 2 .2H 2 The catalyst was impregnated in O solution at 80°C for 10 hr, and the loading of Sn in the catalyst reached 1 wt%, and then dried at 120°C for 6 hr. The dried samples were then calcined in an air atmosphere in a muffle furnace at a temperature of 550° C. for 4 hrs. Sn / SAPO-34 / Al after firing 2 o 3 powder with 0.03M H 2 PtCl 6 ·6H 2 The O solution was impregnated at 80° C. for 4 hr, so that the mass percentage of Pt in the final catalyst was 0.5%. It was then dried at 120°C for 6hrs, and then fired in a muffle furnace at 550°C for 4hrs. Prior to reaction evaluation, all catalyst samples were dechlorinated with steam at 500°C for 8 hr; then reduced with hydrogen at 550°C for 12 hr.

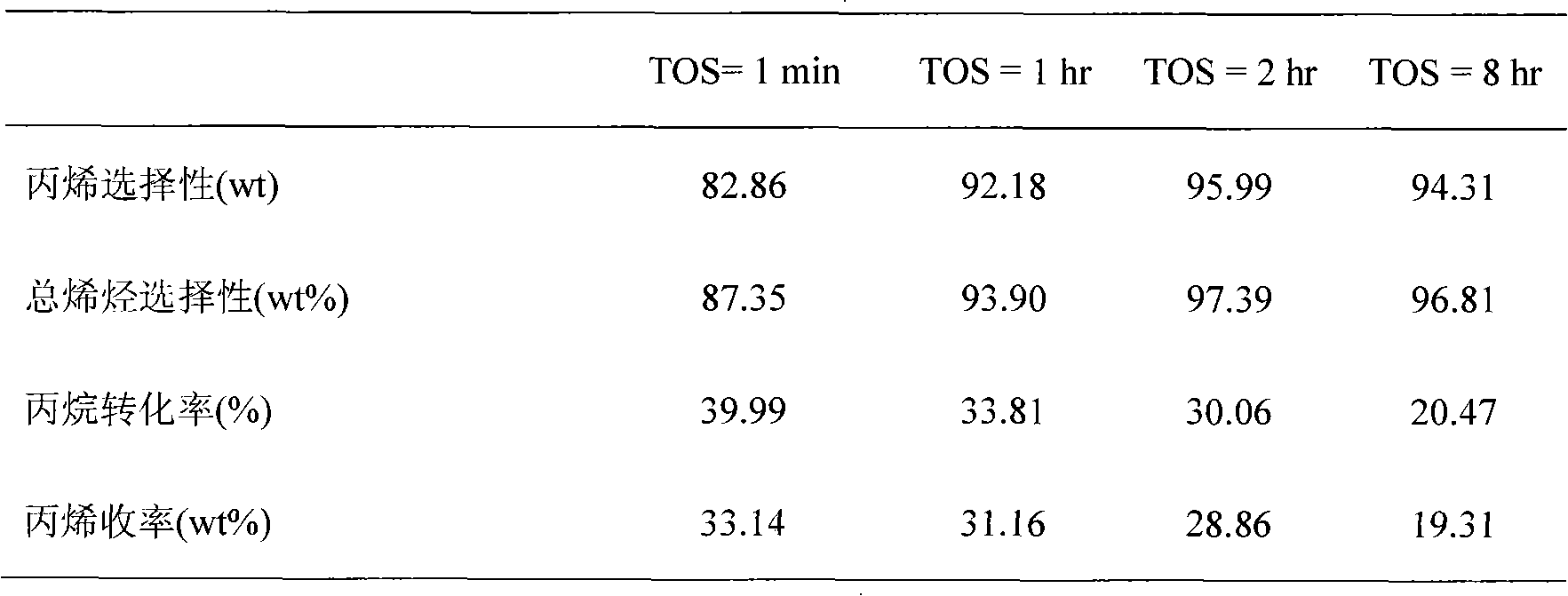

[0028] The catalyst evaluation conditions are as follows: fix...

Embodiment 2

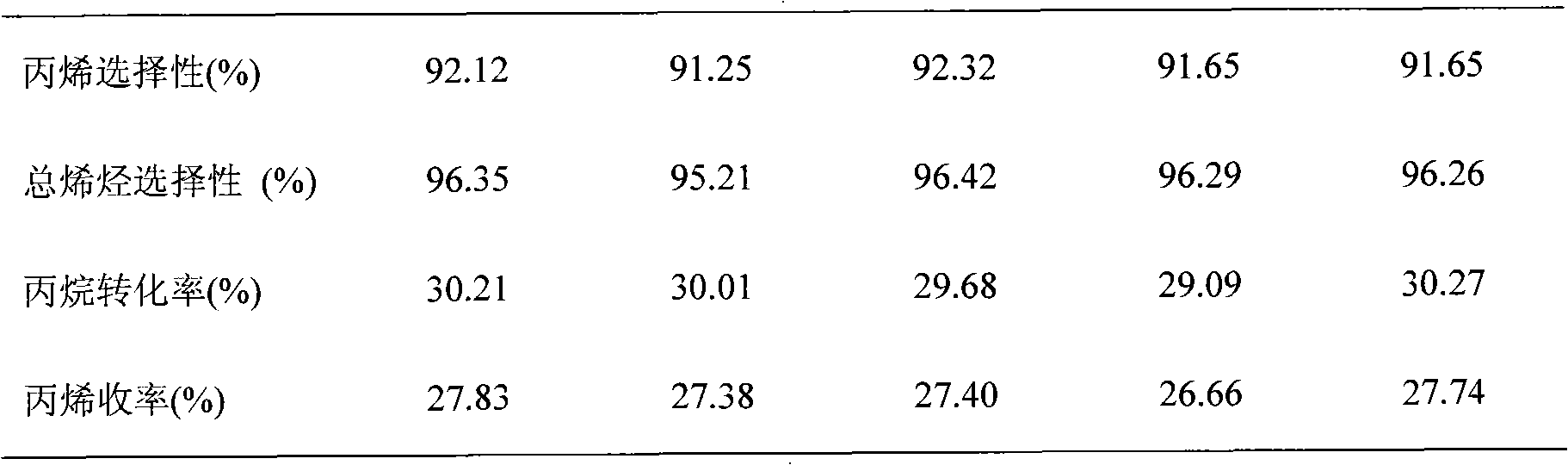

[0032] The catalyst in Example 1 was regenerated, chlorinated, refreshed and reduced after 8 hours of reaction, and then propane dehydrogenation reaction was carried out. The regeneration temperature is 650°C, the regeneration atmosphere is water vapor and nitrogen, the partial pressure of water vapor is 50%, and the regeneration time is 2hr; 2 Cl 2 h 4 , CCl 4 、C 2 Cl 4 h 2 、C 2 Cl 2 h 2 and C 3 Cl 2 h 4 , the chlorination temperature is 500°C, the chlorination space velocity is 10ml / g / hr, and the chlorination time is 2hr; the reducing agent is pure hydrogen, the reduction temperature is 500°C, and the reduction time is 4hr.

[0033] The catalyst evaluation conditions are as follows: fixed bed reactor, catalyst loading 1g, reaction temperature 620°C, weight space velocity 2.00hr -1 , the reaction pressure is 0.1MPa, the H in the raw material 2 The molar ratio to propane is 0.3. When the reaction was carried out for 2hr -1 The experimental results are shown in T...

Embodiment 3

[0038] Mix SAPO-17, SAPO-18, SAPO-44, SAPO-53 and SAPO-5 molecular sieves and alumina respectively, and granulate into a clover shape with an equivalent diameter of 3mm, wherein the content of alumina in the mixed carrier is 25wt% . Then the carrier was in 0.20M SnCl 2 .2H 2 The catalyst was impregnated in O solution at 80°C for 10 hr, and the loading of Sn in the catalyst reached 10 wt%, and then dried at 120°C for 6 hr. The dried samples were then calcined in an air atmosphere in a muffle furnace at a temperature of 550° C. for 4 hrs. Sn / SAPO-34 / Al after firing 2 o 3 powder with 0.03M H 2 PtCl 6 ·6H 2 The O solution was impregnated at 80 °C for 4 hr, so that the Pt content in the final catalyst was 2 wt%. It was then dried at 120°C for 6hrs, and then fired in a muffle furnace at 550°C for 4hrs. Prior to reaction evaluation, all catalyst samples were dechlorinated with steam at 500°C for 8 hr; then reduced with hydrogen at 550°C for 20 hr. Catalyst made of Pt / Sn / SAP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com