Method and device for testing laser absorptivity of powdery material

A technology of powder materials and testing methods, which is used in the testing of the laser absorption rate of micron or nano-scale powder materials, and the detection of laser absorption characteristics of powder materials, which can solve the problems that restrict the wide application of powder laser cladding technology and are difficult to effectively characterize powder materials. Absorption rate and other issues, to avoid poor contact, the method is simple and easy, and the versatility is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

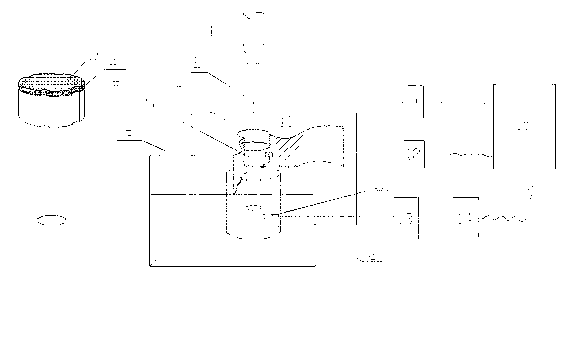

[0035] Such as figure 1 shown.

[0036] A kind of concrete steps of the testing method of powder material laser absorptivity are as follows:

[0037] First, dry the powder to be tested in a drying oven at a temperature of 110-130°C and a drying time of not less than 6 hours; then, place the heat transfer body 5 on the surface of the powder and wash it with acetone to remove dust and other adherents on it , evenly coat a layer of heat-conducting silicone grease 4 on the powder surface of the heat transfer body 5 after cleaning, and the thickness of the heat-conducting silicone grease 4 is not more than 0.5 mm; The powder surface of the heat transfer body 5 covered with thermal grease is uniformly covered with a layer of dried powder to be tested until the thermal grease on the powder surface of the heat transfer body 5 is completely covered by the powder to be tested to form a uniform and dense test powder. Powder layer 3; if the effect of one-time powder feeding or powder s...

Embodiment 2

[0047] Such as figure 1 shown.

[0048] A test device for the laser absorption rate of powder materials, which mainly consists of a laser 1, a beam splitter 2, a heat transfer body 5, an adiabatic box 6, a water storage box 8, a laser power meter 9, a heat transfer body temperature sensor 10, a water body Temperature sensor 11, heat transfer body A / D converter 12, water body A / D converter 13, single-chip microcomputer 14 and computer 15 form; figure 1 As shown, the heat transfer body 5 is in the shape of a pedestal, and the upper end is used for applying heat-conducting silicone grease 4 and bonding the powder layer 3 to be tested. The diameter of one end of the hole, such as figure 1 As shown on the left side of the middle, the diameter of the upper end of the heat transfer body 5 matches the diameter of the countersunk through hole 7 opened at the center of the heat insulating box 6, and the diameter of the lower end matches the diameter of the countersunk through hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com