LED (Light Emitting Diode) performance test box, calibrating method and performance test method

A test box and performance technology, applied in the direction of testing optical performance, single semiconductor device testing, etc., can solve the problems of affecting test results, increasing manpower and time costs, and changing the performance of test samples, etc., to achieve simple operation, simple structure, and applicability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

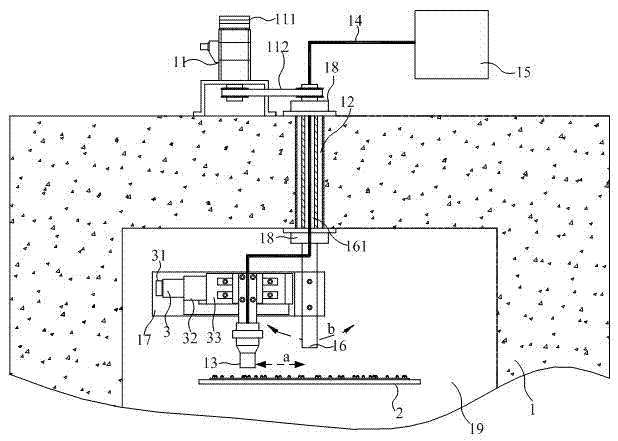

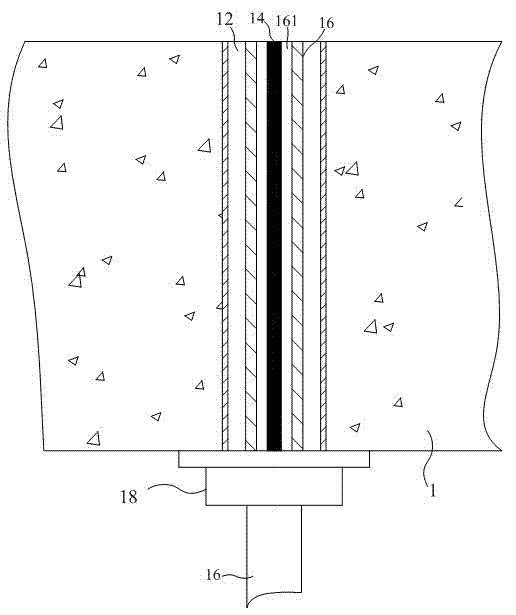

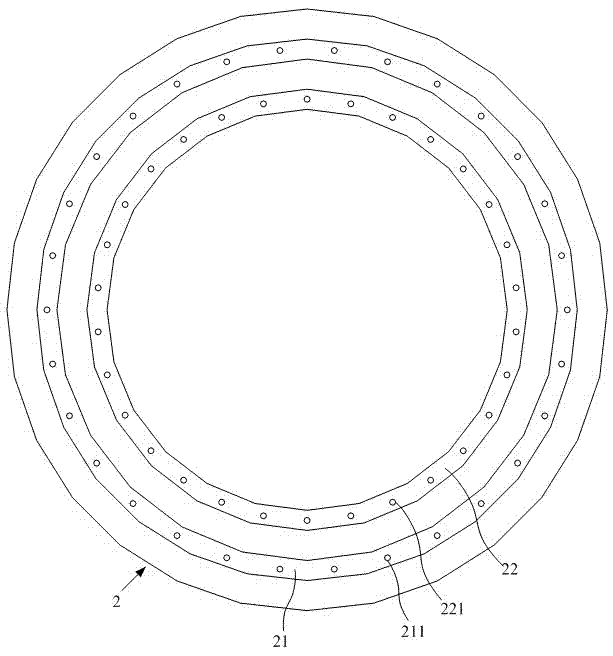

[0031] Such as figure 1 and 2 As shown, a LED performance test box of an embodiment includes a box body 1, a first motor 11, a second motor 3, a light-taking device 13, a rotating shaft 16, a connector 17 and an optical fiber 14, and the box body 1 is provided with a communication The through hole 12 outside the box and the inner cavity 19 of the box body, the rotating shaft 16 and the optical fiber 14 pass through the through hole 12, the light-taking device 13 and the second motor 3 are arranged in the inner cavity 19 of the box body 1, and the first motor 11 is set Outside the box body 1, the first motor 11 drives the rotating shaft 16 to rotate, and one end of the rotating shaft 16 extending into the inner chamber 19 is fixed with the connecting piece 17, so that the first motor 11 can drive the connecting piece 17 for circular motion, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com