Cigarette smoke aerosol real-time testing system

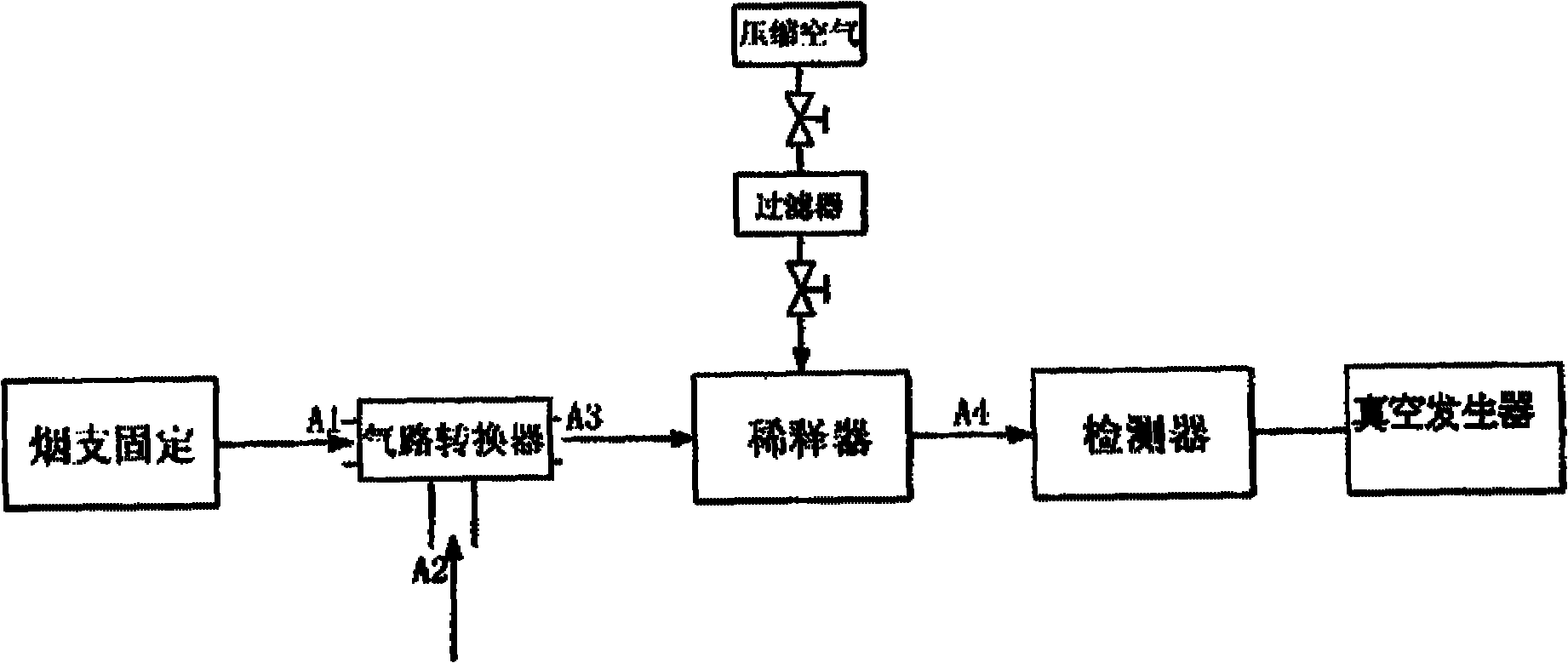

A real-time test, cigarette smoke technology, applied in the preparation of test samples, instruments, analysis materials, etc., can solve the problem of inability to correctly evaluate the real characteristics of fresh aerosol samples, sample concentration, particle size characteristics and other key indicators distortion, mutual Problems such as collision, condensation, side wall adsorption concentration, particle size distribution characteristics, etc., to achieve the effect of highlighting substantive features, compact structure, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

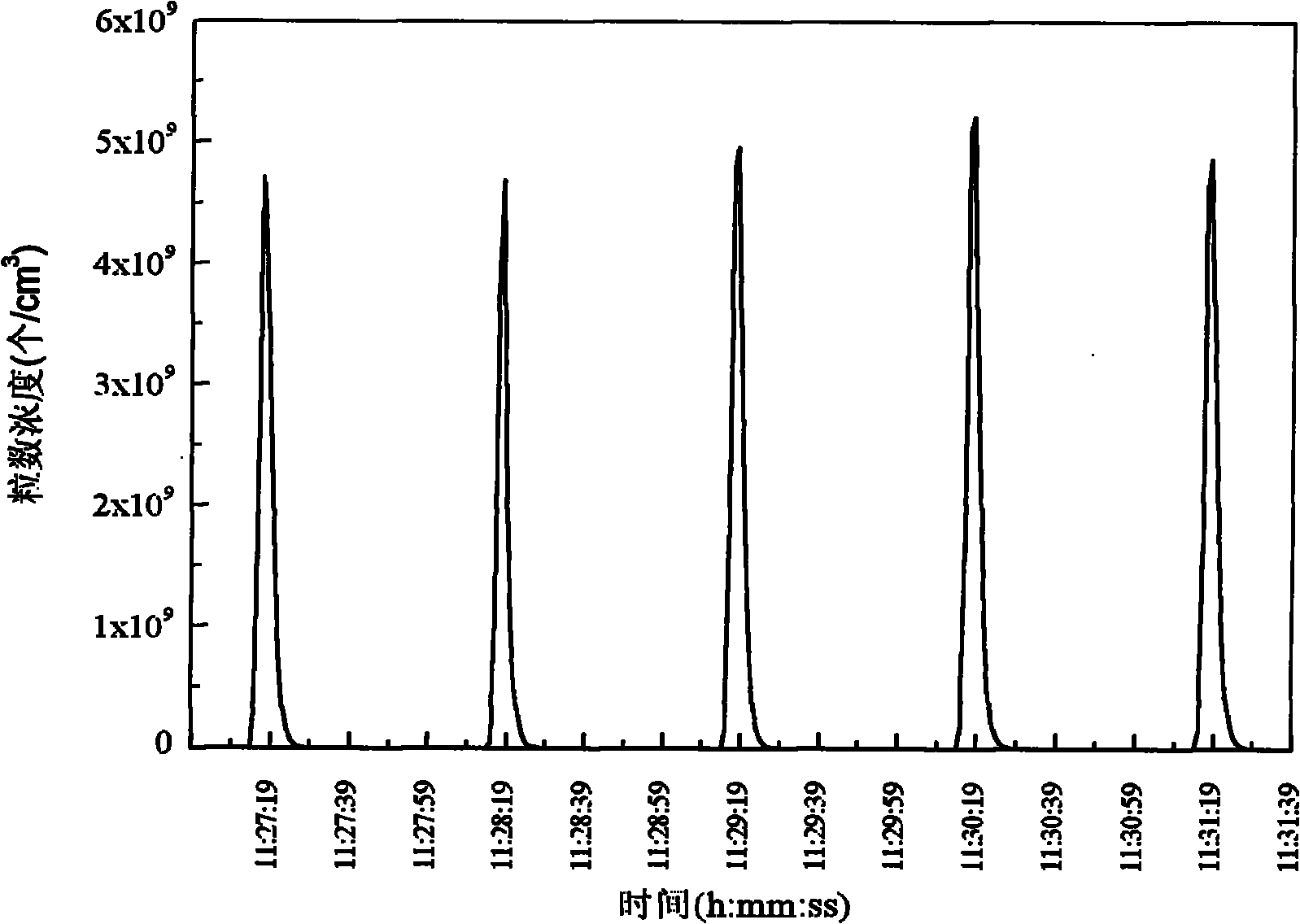

[0029] (1) Put a certain brand of cigarettes in a constant temperature and humidity room to balance for 48 hours. Cigarettes of the same specification were selected as experimental cigarettes. Set the suction duration 2s and the suction interval 58s in the air circuit converter.

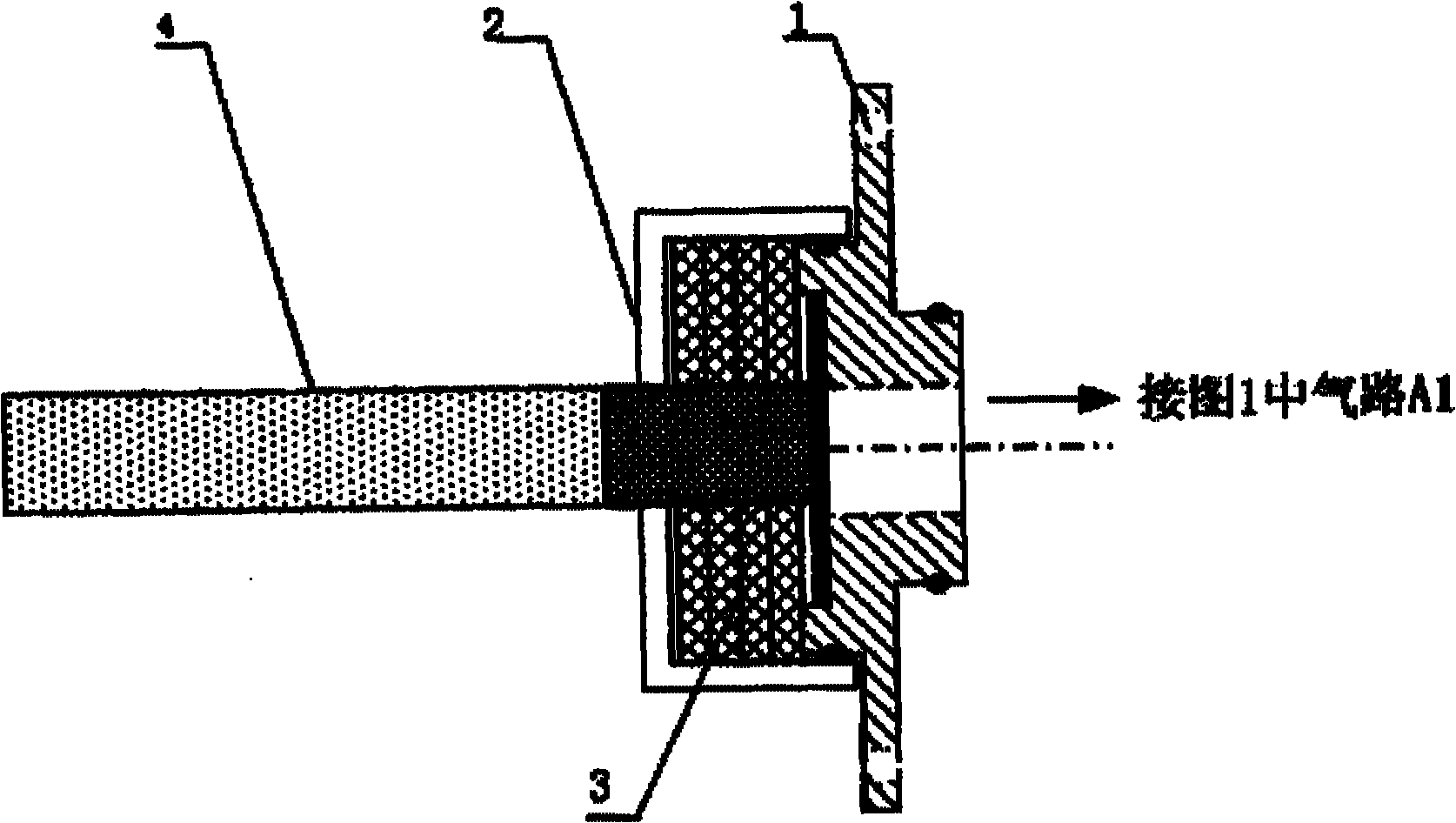

[0030] (2) Turn on the flue gas dilution system and aerosol particle detection system, then adjust the inlet pressure of the diluted gas to the set pressure, calibrate the suction capacity (35±0.5)ml with a soap film flowmeter, until the system pressure is stable. Then light the cigarette and turn on the gas circuit converter at the same time. When the suction is maintained for 2 seconds, the gas channel leads to the smoke gas circuit A1, and the pure gas gas circuit A2 is closed. At this time, the negative pressure generated by the suction source can make the cigarette be drawn. Suck. After one puff of suction, the gas circuit converter controls the gas circuit to switch instantly, the gas channel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com