Calibration method and calibration apparatus for positioning error of position sensitive detector

A positioning error and detector technology, which is applied to the calibration method and calibration device field of high-precision position-sensitive detector position positioning error, which can solve the problem of high-precision position-sensitive detector positioning error, inability to test error correction, and direct measurement of coordinates Operation and other issues to achieve the effect of improving test accuracy and avoiding test errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further elaborated below by specific examples:

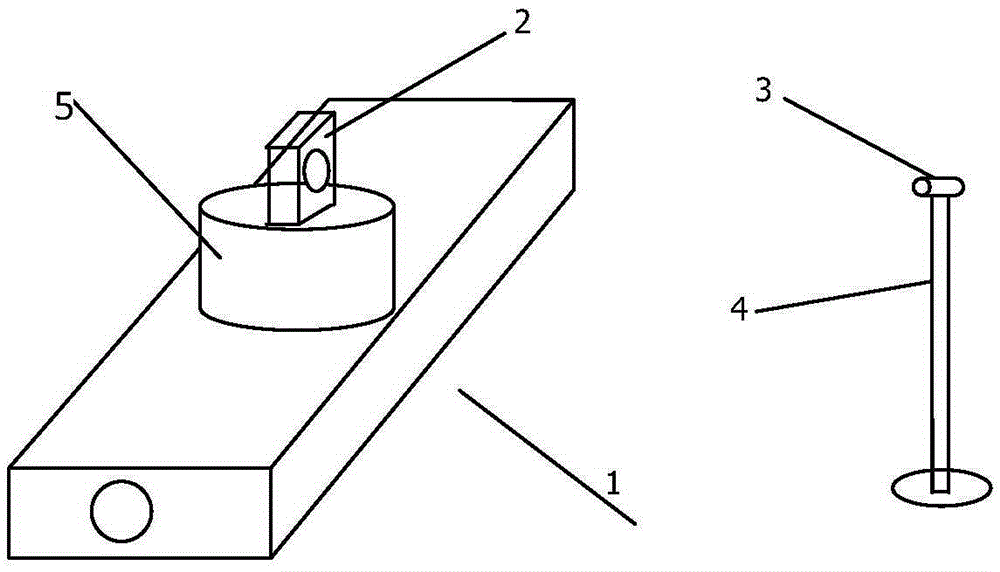

[0024] Such as figure 1 The calibration device for the positioning error of the position-sensitive detector includes an electronically controlled translation stage 1, a single-axis precision turntable 5, a semiconductor laser 3 for emitting a beam to the PSD, and a laser holder 4 for clamping the semiconductor laser; the single-axis The precision turntable 5 is fixed on the electronically controlled translation platform 1, and the PSD2 is placed on the single-axis precision turntable 5; the single-axis precision turntable 5 is fixed to the electronically controlled translation platform 1 by bolts.

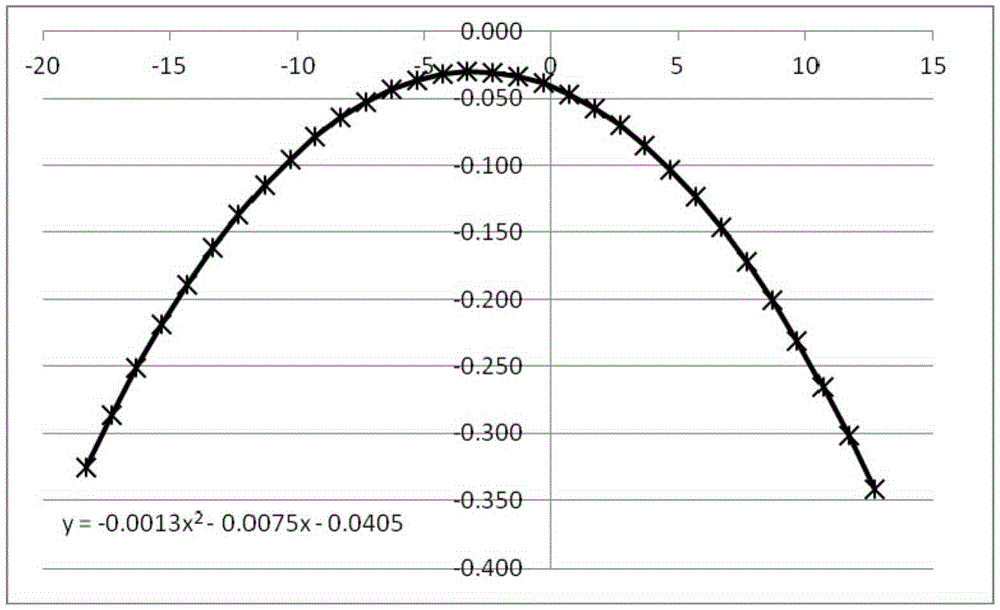

[0025] In the embodiment, in this embodiment, the nominal positioning error of the PSD is -0.03mm, so the angular rotation step of the turntable is determined to be 1°, and the test accuracy of the PSD positioning error can be guaranteed under this rotation step. During the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com