Injecting equipment for direct connection test of novel stamping engine and environment simulation system

A technology of ramjet engine and test environment, which is applied in the direction of engine test, measuring device, machine/structural component test, etc. It can solve problems such as inability to meet the simulated air flow, lack of ejection capability requirements, and low ejection efficiency , to maximize economic benefits and cost control, high reliability, and small construction scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

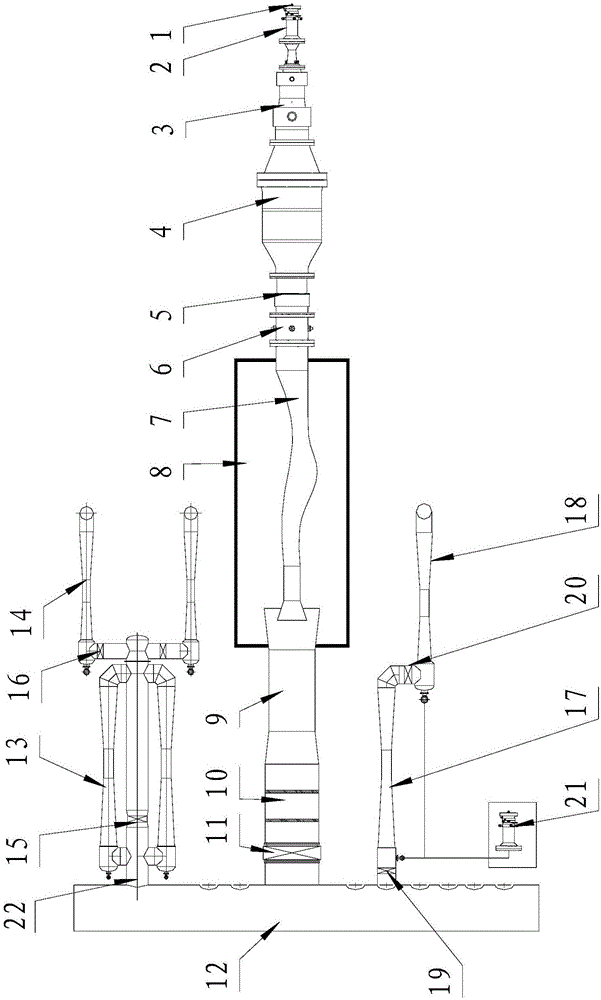

[0045] The injection device provided by the present invention is applied in the simulation system of the direct connection test environment of the new type of ramjet engine, and its structural composition is as follows: figure 1 shown.

[0046] The injection device adopts a modular design, which includes 8 steam injection units installed on the gas collection pipe 12. According to the injection requirements of different working conditions, a single or multiple steam injection units can be used to meet the requirements of the ramjet engine. Long-range heat test exhaust requirements.

[0047] Each steam injection unit includes a large-flow steam generator 21 with a working flow rate of 110kg / s and a group of two-stage steam injection pumps, wherein the two-stage steam injection pump consists of the first steam injection pump 17 and the second steam injection pump Composed of 18 series.

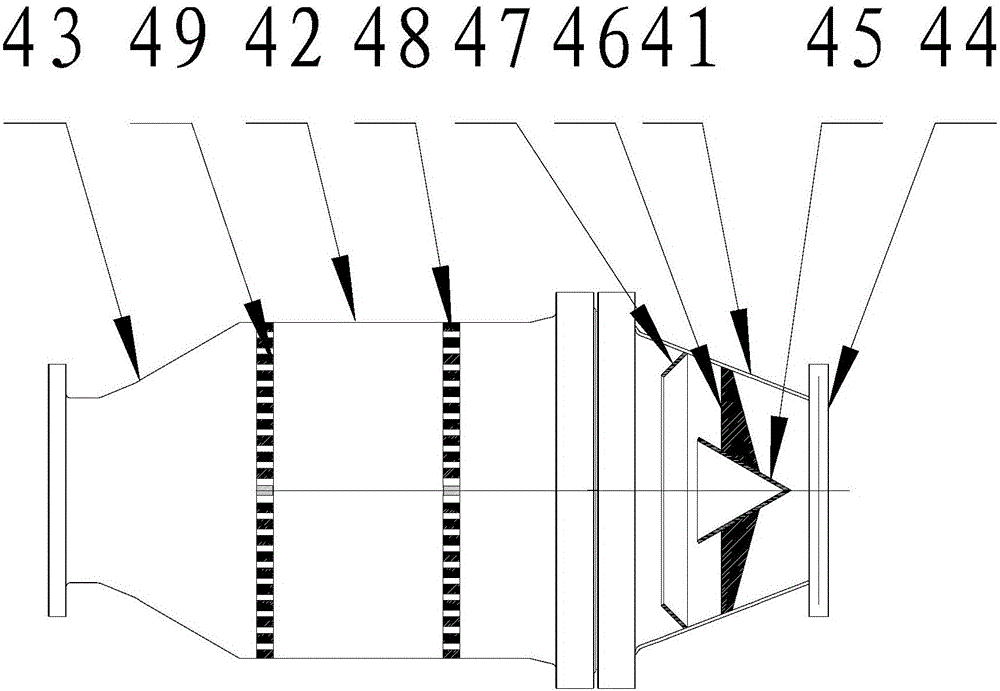

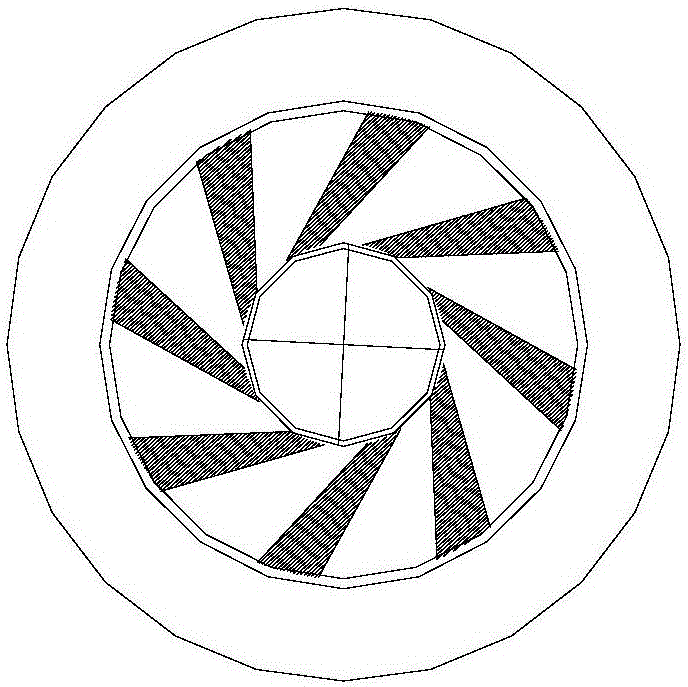

[0048] Both the first steam injection pump 17 and the second steam injection pump 18 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com