Dynamic simulation test method and testing machine for plastic support bearing used for suspension

A technology of dynamic simulation test and support bearing, applied in the direction of mechanical bearing test, etc., can solve the problem of inability to simulate the actual working conditions of the bearing, and achieve the effect of real test results and enhanced flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

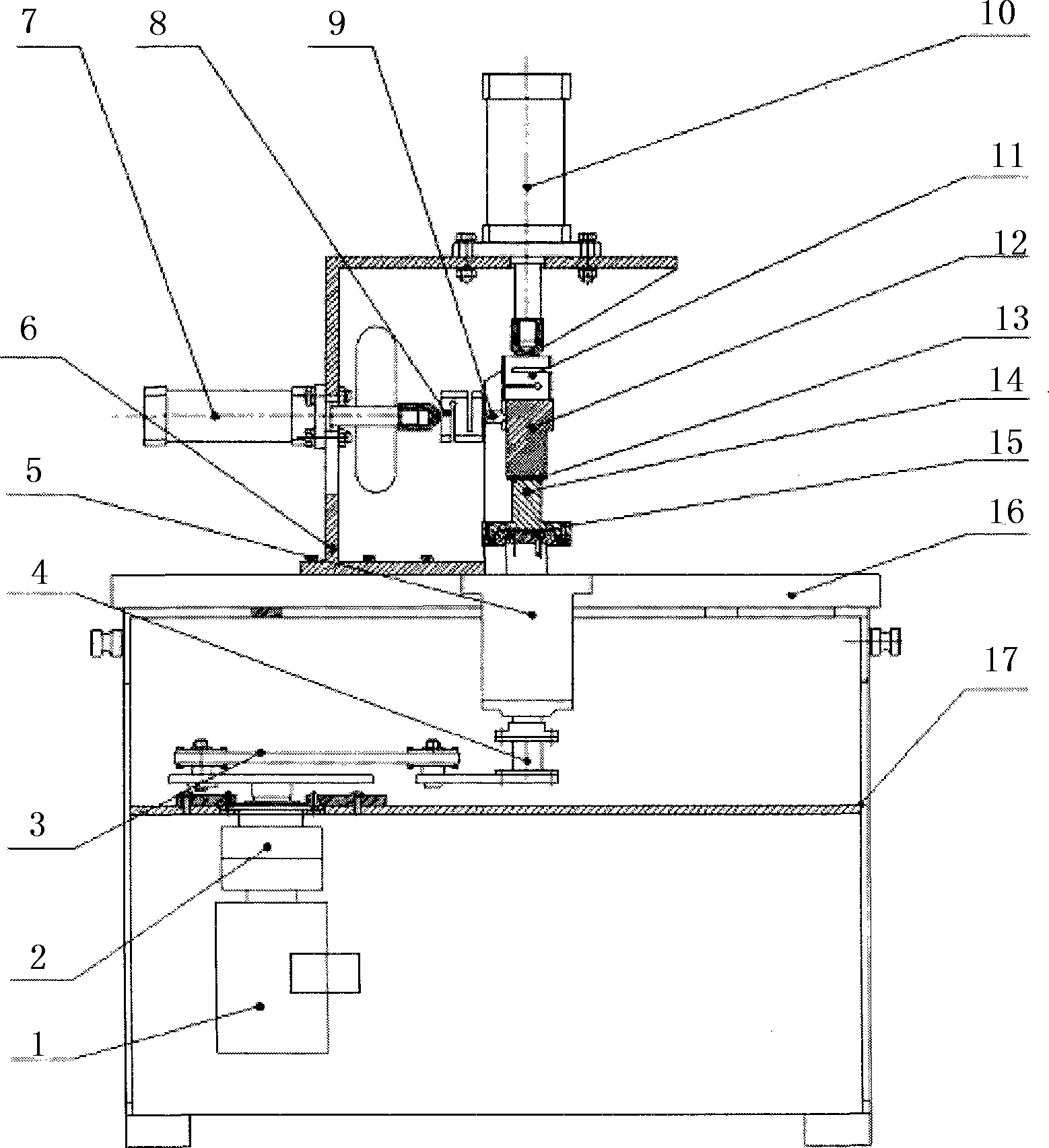

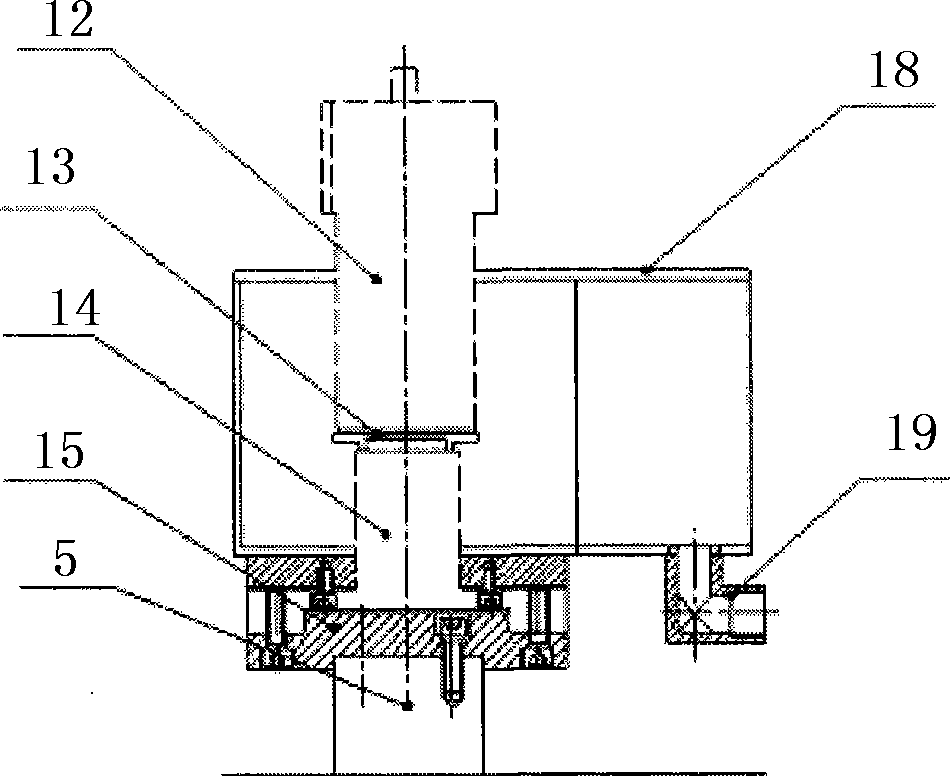

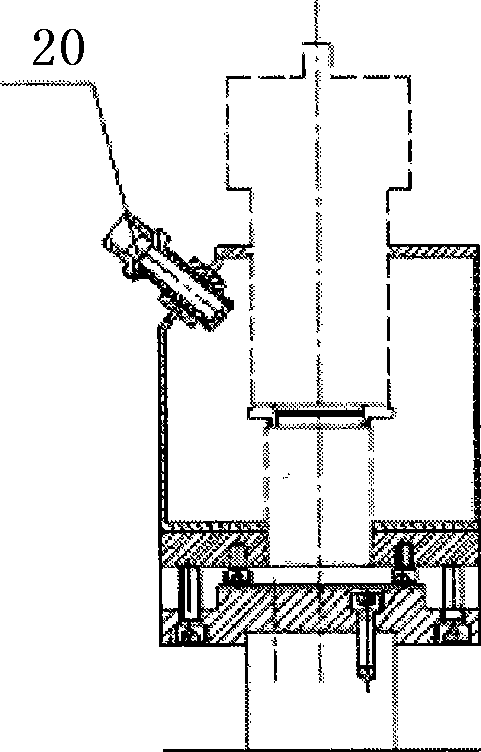

[0022] The dynamic simulation test method of the plastic support bearing for automobile suspension of the present invention is to place the bearing to be tested flat on the vertical test shaft, the test shaft can swing intermittently with the driving device, and the intermittent swing is provided by the multi-link in the driving device. The mechanism converts the rotation of the variable frequency motor into a swing within ±45° on the test shaft to simulate the actual motion state of the bearing under test. At the same time, a loading device is set on the bearing under test. The loading device includes axial loading and radial loading , Axial loading and radial loading are both implemented by a loading block placed on the bearing under test, wherein the axial loading is to set an axial force sensor on the loading block, and the axial force sensor is controlled by a fixed axial loading cylinder→ Loading block→the bearing under test implements axial loading. Radial loading is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com