Simulation tester for self healing of asphalt concrete cracks

A kind of asphalt concrete and simulation test technology, applied in the direction of material inspection products, etc., can solve problems such as self-healing behavior of cracks that have not yet been developed, and achieve the effect of simple structure, reasonable design, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

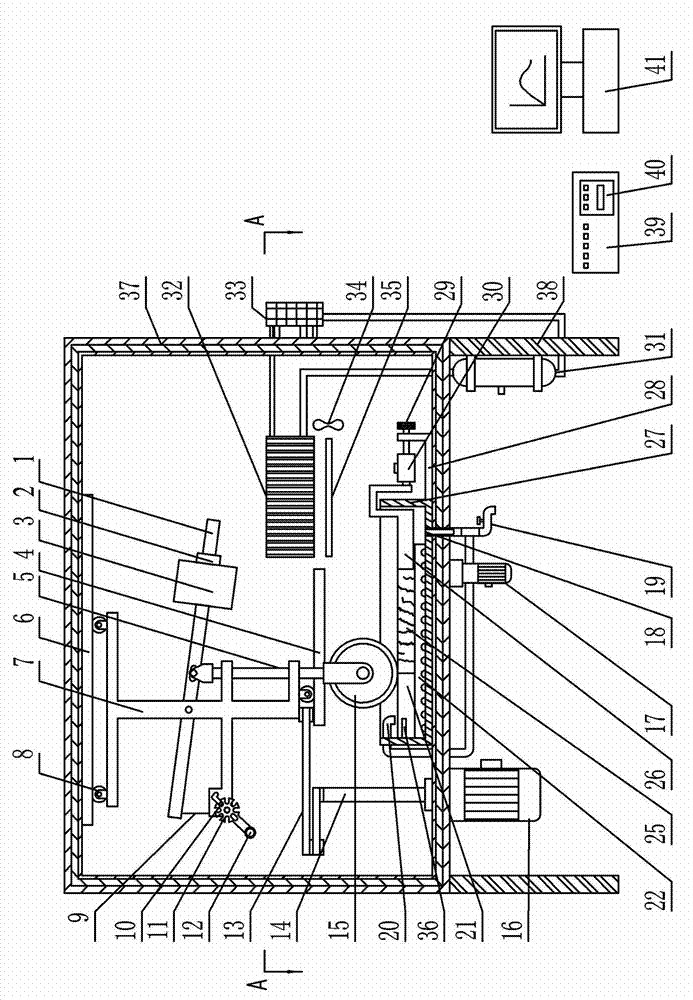

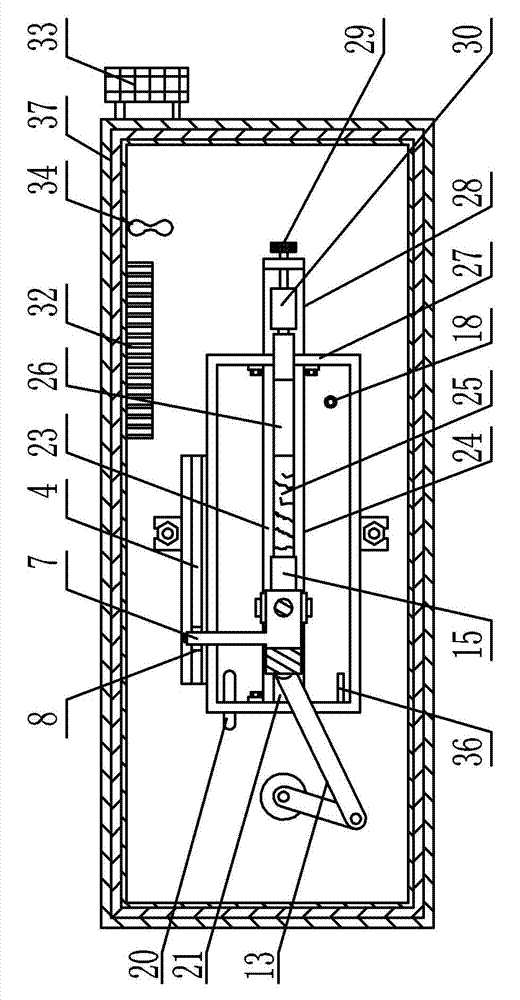

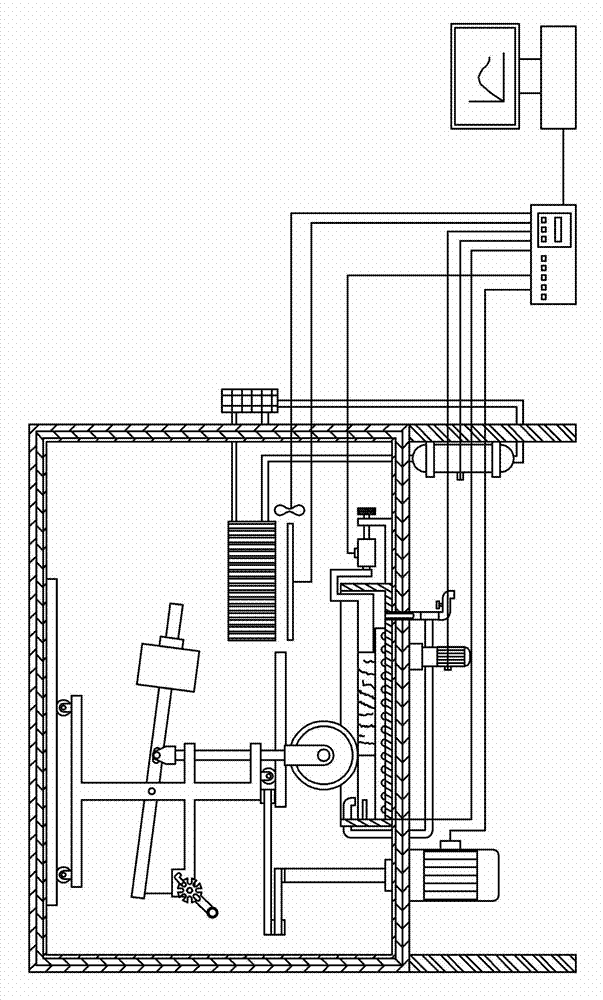

[0029] Lever 1, counterweight fastening nut 2, counterweight 3, lower rail 4, pressure sliding rod 5, upper rail 6, loading frame 7, pulley 8, pull rope 9, locking pin 10, shaking wheel 11 , crank handle 12, crank connecting rod 13, coupling shaft 14, test wheel 15 etc. have formed the wheel load simulation device of the present invention. The upper slide rail 6, the lower slide rail 4 and the rigid water tank 27 are parallel to each other and ensure rigid connection in a vertical plane. The parallelism ensures that the loading frame 7 can reciprocate horizontally along the upper and lower rails, and the rigid connection ensures that the test wheel can apply sufficient load to the specimen; the contact surfaces of the upper rail 6 and the lower rail 4 and the pulley 8 are uniform. It is a groove type design, which ensures that the loading frame 7 will not escape from the slide rail. A "T"-shaped horizontal strut protrudes from the upper end of the loading frame, and its horiz...

Embodiment 2

[0047] The above descriptions are only illustrative specific implementations of the present invention, and are not intended to limit the scope of the present invention. Any equivalent changes and modifications made by those skilled in the art without departing from the concept and principles of the present invention, such as Change the size or quantity of the test wheel 15 and change the size or quantity of the specimen holders 21, 22, 23 and 24, so as to test a plurality of specimens 25 at the same time, or change the specific structure of the loading device, or change the test wheel 15 loading methods, such as the test wheel 15 does not do horizontal reciprocating movement and the test piece 25 does reciprocating movement, or a group of evaporators 32 and heating pipes 35 are set in the rigid water tank 27, which can constitute a specific embodiment of the present invention. All should belong to the protection scope of the present invention, and will not be described in detai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com