A multi-axis creep fatigue prediction method based on ABAQUS

A prediction method and creep technology, applied in the direction of using stable tension/pressure to test material strength, measurement device, knowledge expression, etc., can solve the problems of inaccurate creep fatigue analysis and prediction, poor convergence, complex programming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The ABAQUS-based multiaxial creep fatigue prediction method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

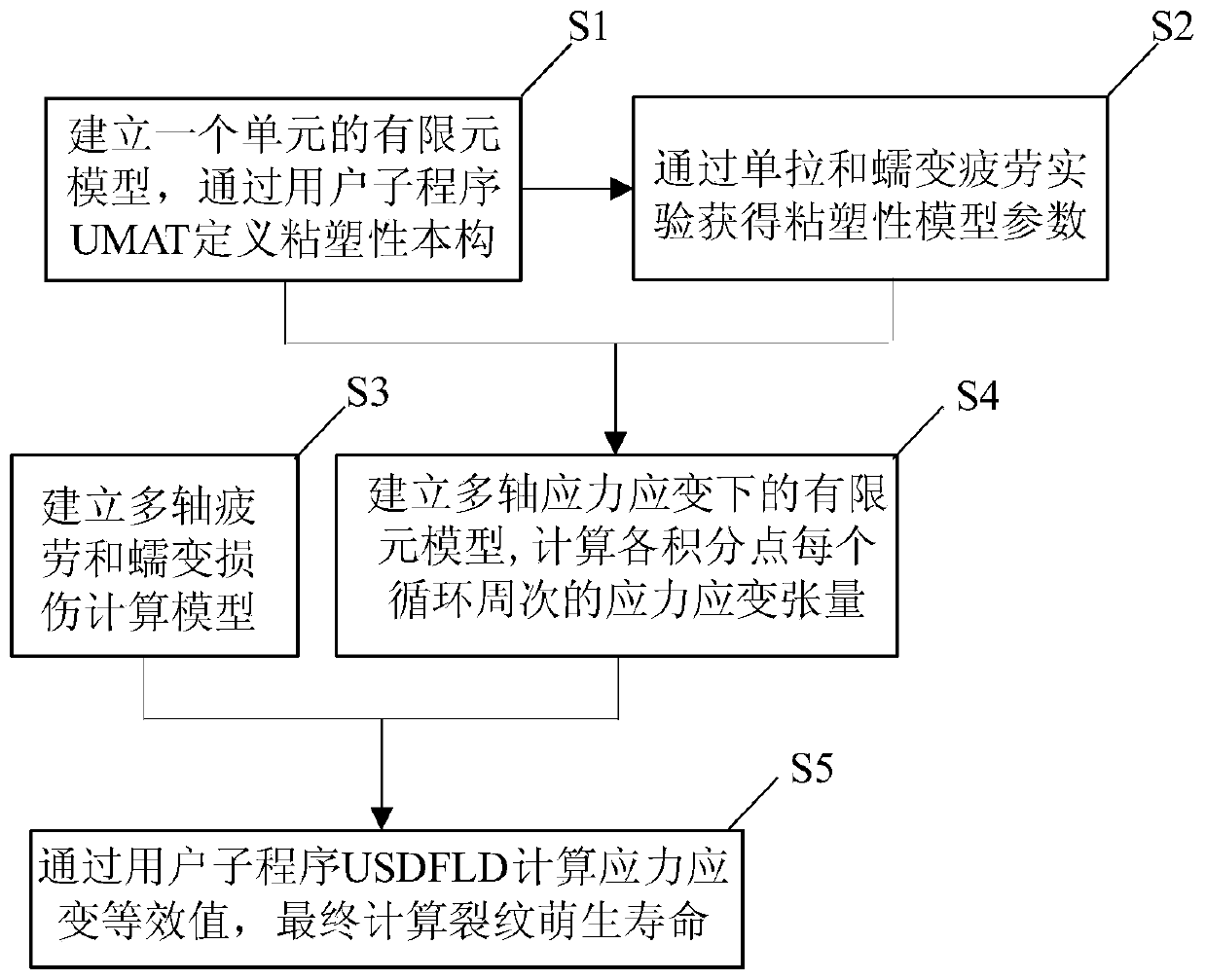

[0067] figure 1 It is a flow chart of the ABAQUS-based multiaxial creep fatigue prediction method in one embodiment of the present invention.

[0068] Such as figure 1 As shown, in this embodiment, the ABAQUS-based multiaxial creep fatigue prediction method includes steps:

[0069] S1: Establish the ABAQUS finite element model, and define the viscoplastic constitutive equation of the material to be tested in the process of cyclic loading through the user subroutine UMAT;

[0070] S2: determining the model parameters required by the viscoplastic constitutive equation;

[0071] S3: Establish a fatigue damage calculation model and a creep damage calculation model of the multiaxial stress-strain state of the material to be tested;

[0072] S4: Establish the ABAQUS finite e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com