Tight reservoir horizontal well volume fracturing process

A volume fracturing and tight reservoir technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems that it is difficult to achieve the expected effect, the overall permeability of the reservoir is not improved, and the permeability of the reservoir is poor. , to achieve the effect of solving insufficient transformation, improving the success rate, and expanding the volume of transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

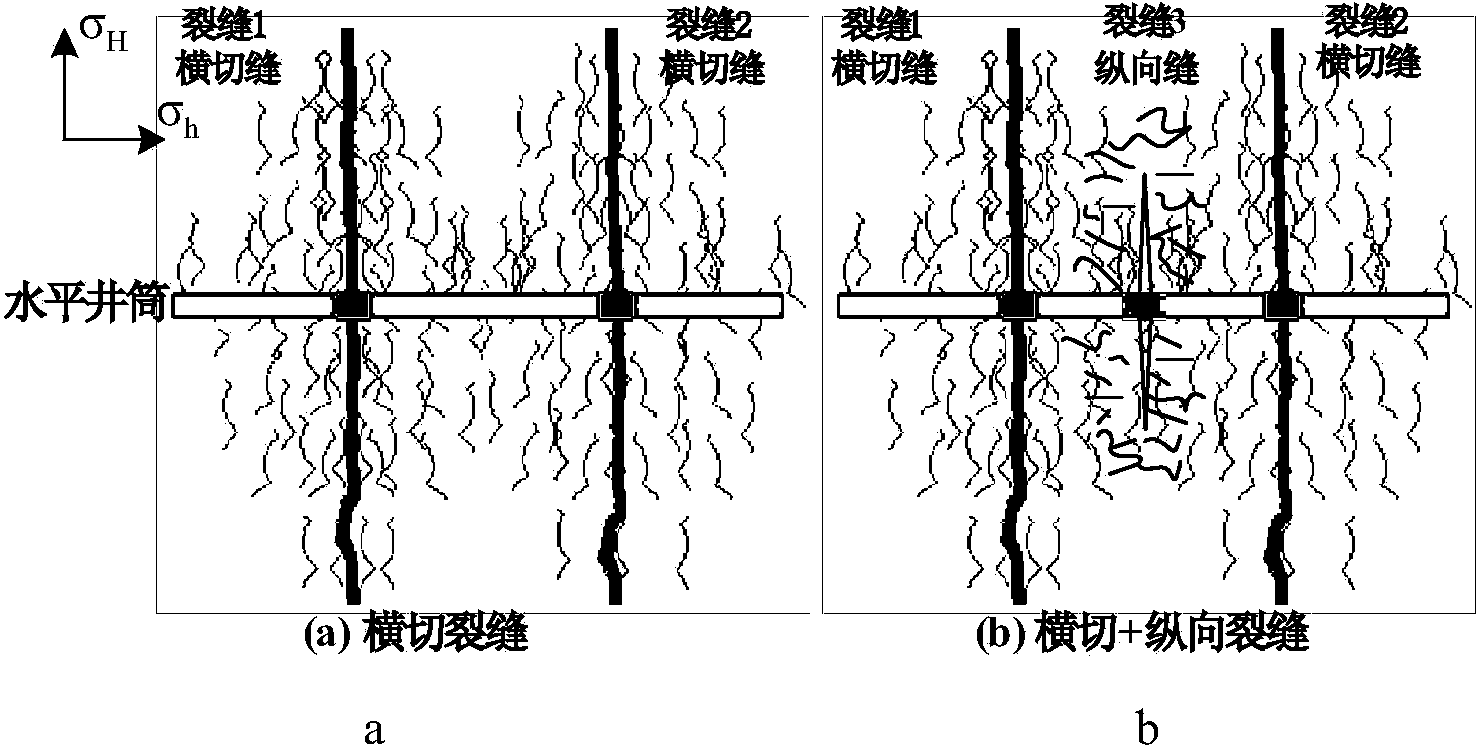

[0019] A volumetric fracturing technology for horizontal wells in tight reservoirs, mainly comprising the following steps:

[0020] 1) Collect data such as in-situ stress magnitude and direction, horizontal well orientation, length, reservoir Young's modulus, Poisson's ratio, and logging interpretation results, and use them as the basis for calculating complex fractures generated by volume fracturing of horizontal wells in tight reservoirs Induced stress basic parameters;

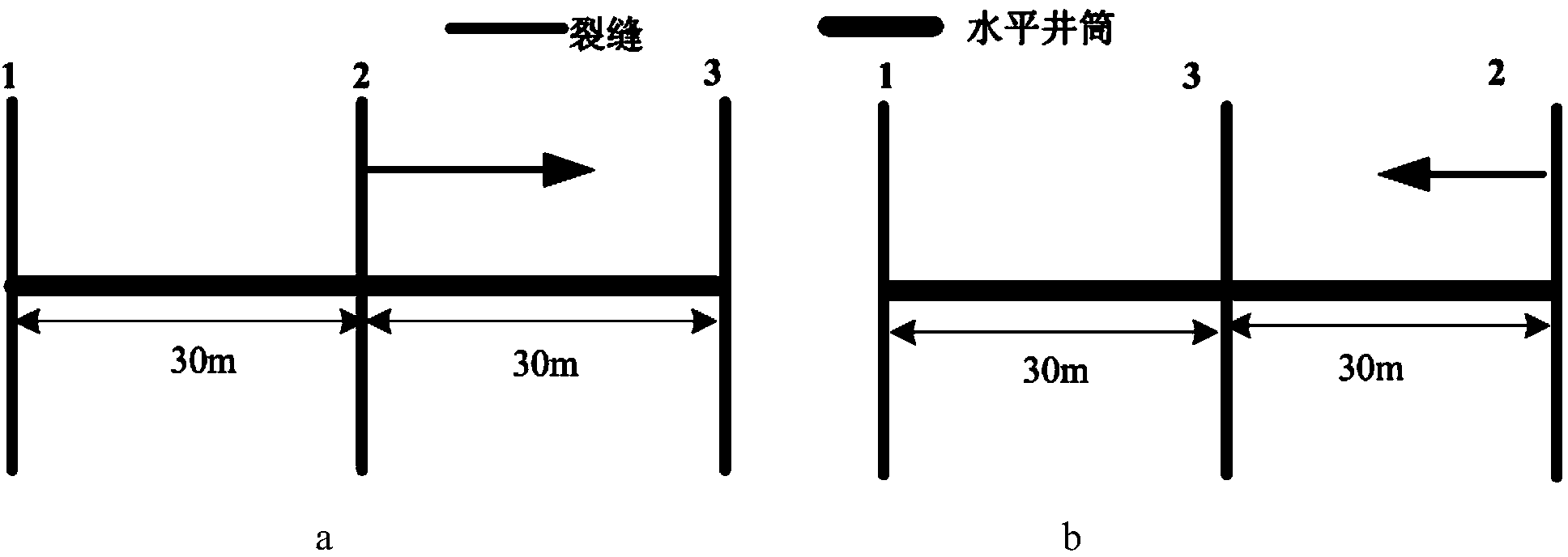

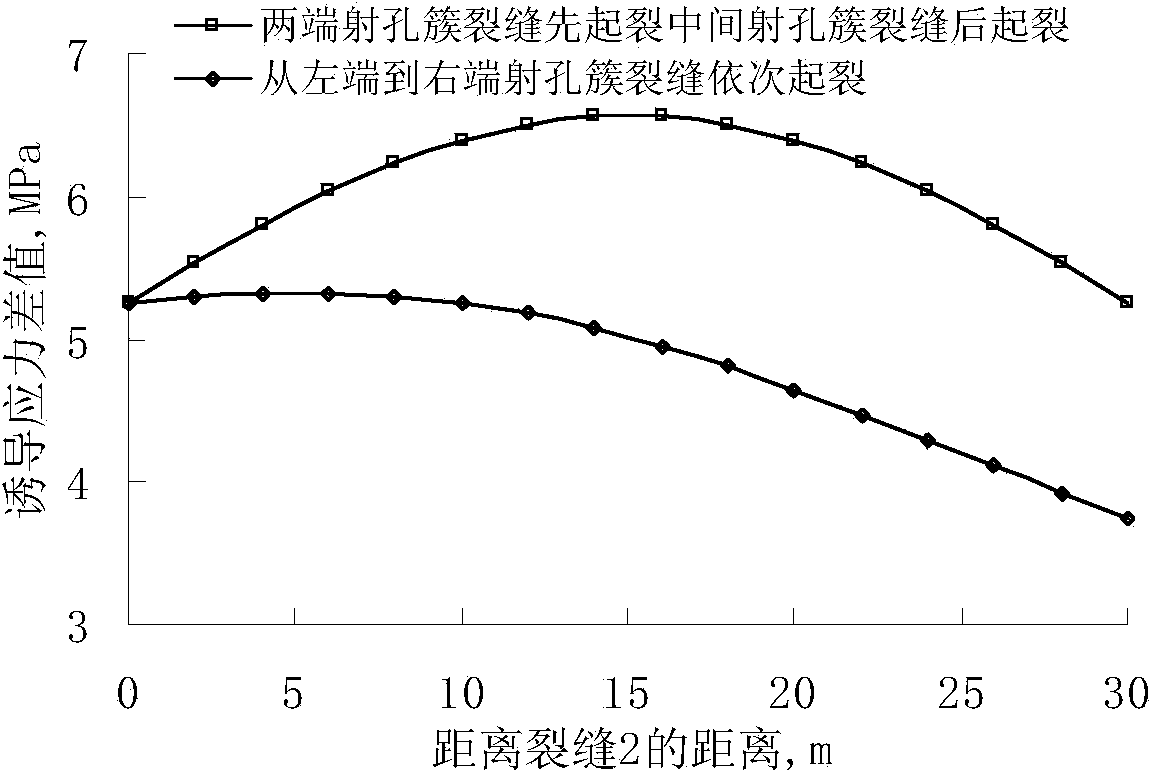

[0021] 2) According to the physical properties of the reservoir, compare the induced stress difference changes of three or more perforation clusters under different fracture initiation sequences in the same fracturing section, and select the maximum induced stress difference as the target to optimize the fracture initiation sequence of perforation clusters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com