Method for determining crack initiation strength of rock under compressive conditions

A technology for crack initiation strength and determination method, which is applied in the direction of applying stable tension/pressure to test material strength, etc., can solve problems such as interference with accurate identification of crack initiation strength values, and achieve easy popularization and application, uniqueness, and simple and reliable methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, the crack initiation strength of the rock is determined under uniaxial compression conditions, and the following operations are performed now:

[0029] (1) Process the complete core drilled in the preselected area of the high-level radioactive waste geological repository in Beishan, Gansu Province, and prepare a cylindrical rock specimen with a height-to-diameter ratio of 2:1. The diameter of the rock specimen used in this example is 50mm , the height is 100mm.

[0030] (2) Install the rock specimen on the sample table of the press, the model of the press is: MTS815 (manufactured by MTS Company of the United States).

[0031] (3) Install axial and circumferential extensometers in the middle of the rock sample.

[0032] (4) Use the load control mode of the press to perform a uniaxial compression test on the specimen, with the loading rate set at 0.75MPa / s, until the specimen is destroyed, and the test ends.

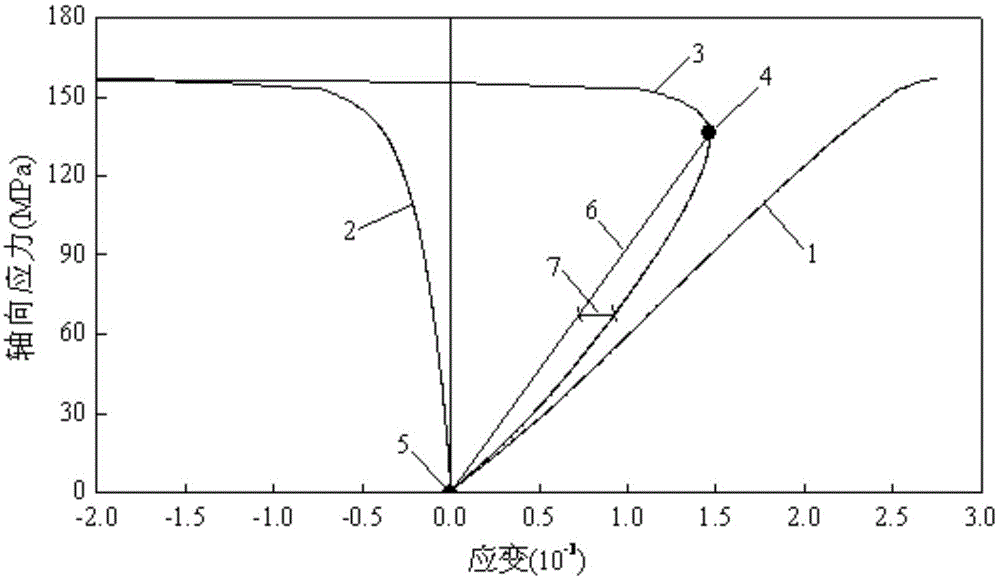

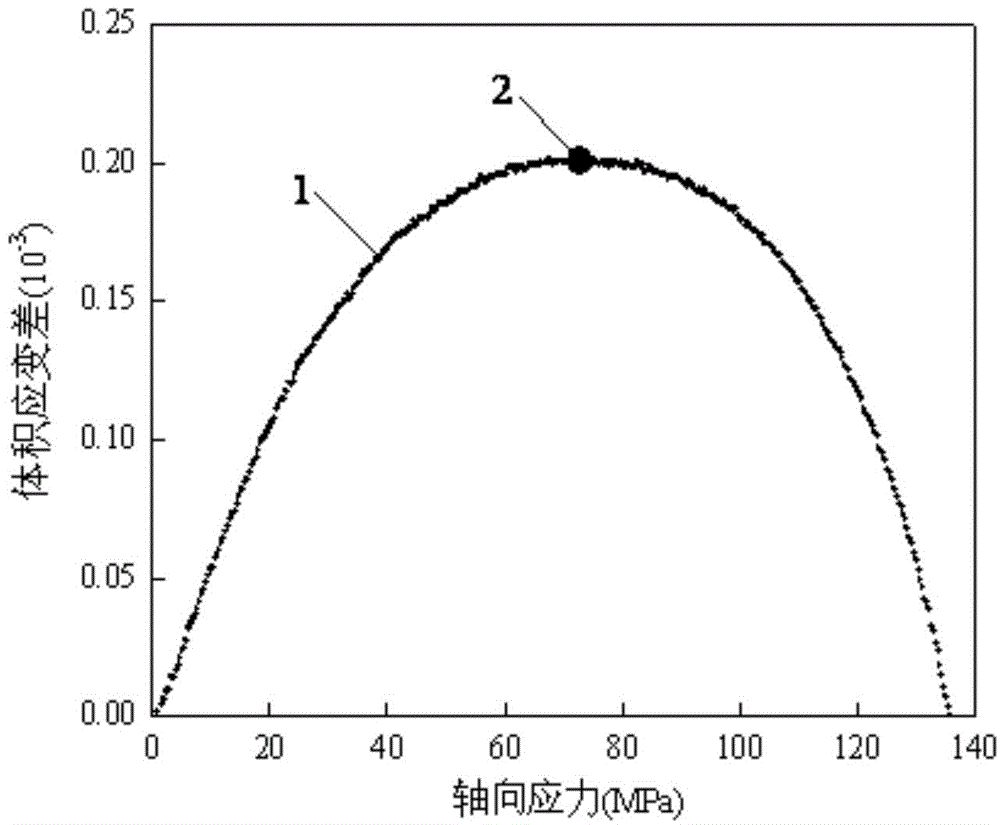

[0033] (5) if figure 1 shown, accordi...

Embodiment 2

[0040] In this embodiment, the determination of rock crack initiation strength under triaxial compression conditions is performed as follows:

[0041] (1) Process the complete core drilled in the preselected area of the high-level radioactive waste geological repository in Beishan, Gansu Province, and prepare a cylindrical rock specimen with a height-to-diameter ratio of 2:1. The diameter of the rock specimen used in this example is 50mm , the height is 100mm.

[0042] (2) Install the rock specimen on the sample table of the press, the model of the press is: MTS815 (manufactured by MTS Company of the United States).

[0043] (3) Install axial and circumferential extensometers in the middle of the rock sample.

[0044] (4) Apply confining pressure to the rock sample through the surrounding rock system of the press, and the confining pressure value used in this example is 20MPa.

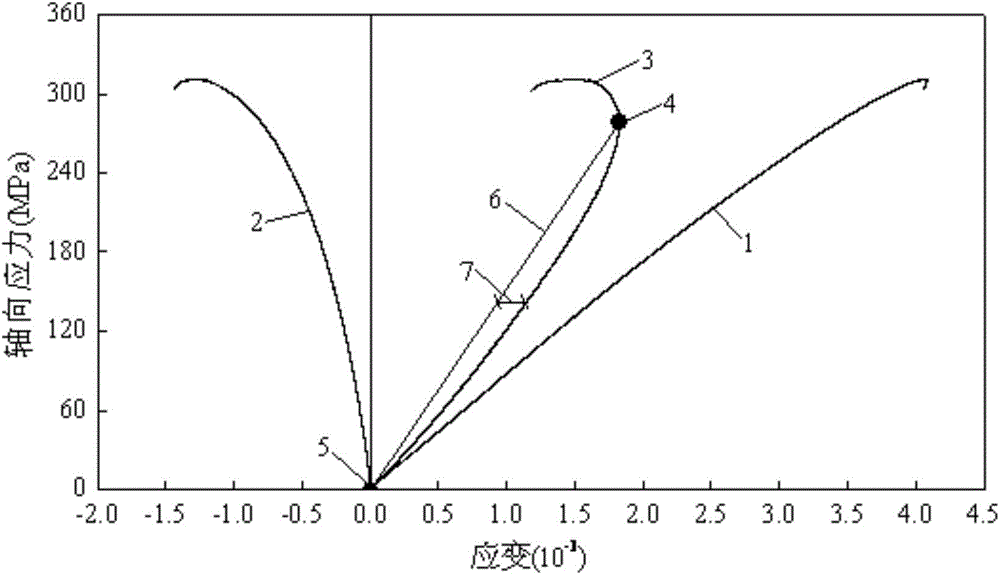

[0045] (5) Use the load control mode of the press to perform a triaxial compression test on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com