High-speed chain lubricating grease and preparation method thereof

A lubricating grease and chain technology, which is applied in the field of high-speed chain lubricating grease and its preparation, can solve the problems of thinning and loss, short chain replacement cycle, and shortened life of itself, so as to achieve resistance to impact load and vibration load, good economy and Market value, effect of reducing coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

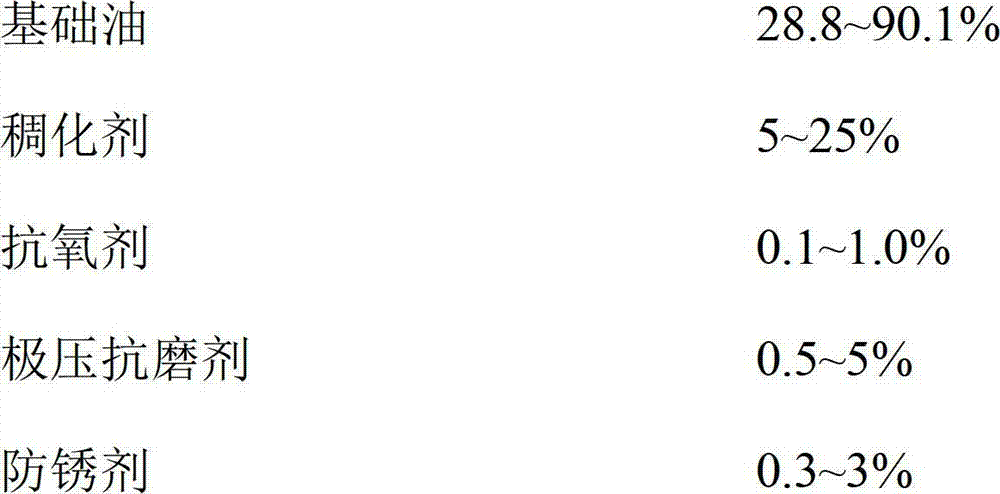

Method used

Image

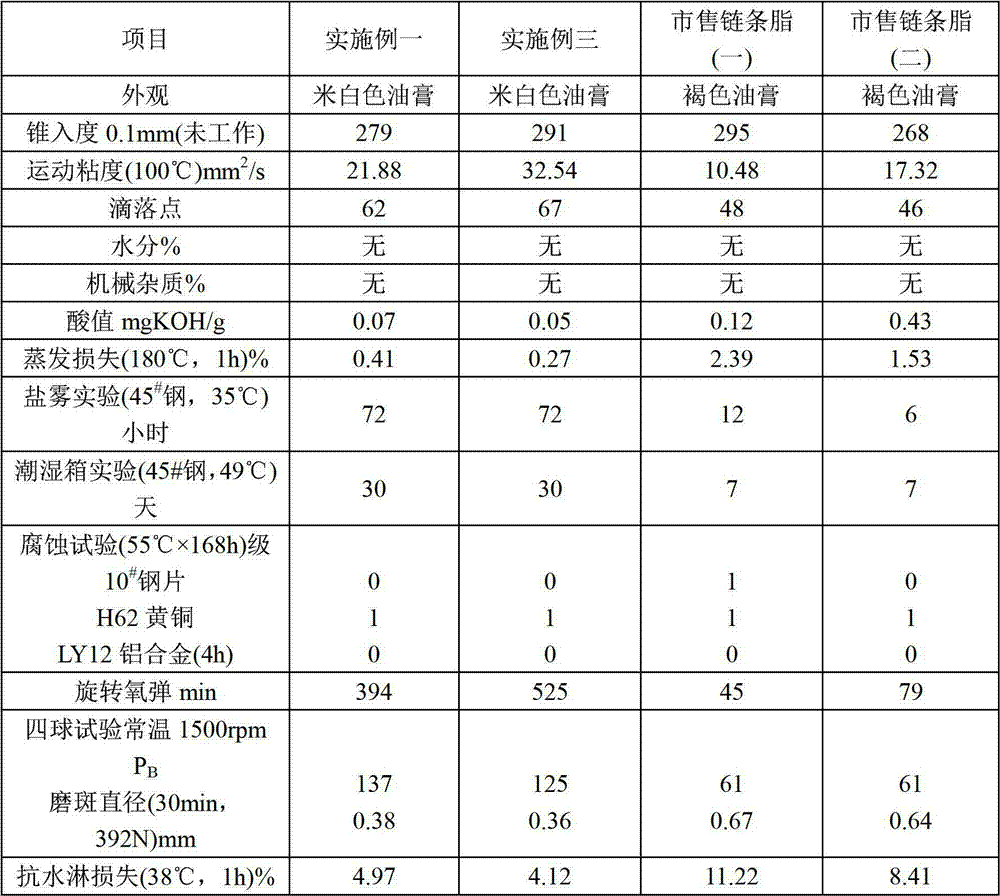

Examples

Embodiment 1

[0033] 1) 577 kg of hydroisomerization 500SN, 50 kg of di-octyl sebacate (V40=8.52mm 2 / s), 100 kilograms of polyisobutylene PB1300 (tackifier), 20 kilograms of polymethacrylate 8-450 (tackifier), 100 kilograms of No. 85 microcrystalline wax (thickener), 50 kilograms of polyethylene wax ( thickener) into the reaction kettle together, heat and stir to raise the temperature to 100°C, and stir at constant temperature for 45 minutes to melt the microcrystalline wax and polyethylene wax, then raise the temperature to 120°C, vacuumize to -0.08MPA, and maintain constant temperature and constant vacuum for dehydration 2 hours.

[0034] 2) Add 3 kg of phenyl-α-naphthylamine (T531), 2 kg of 2,6-di-tert-butyl-p-cresol (T501), 1 kg of benzotriazole (T706), and 20 kg of oily potassium borate in sequence (T361), 50 kg of polytetrafluoroethylene superfine powder, stirring and mixing for 20 minutes to melt the solid additive, then add 20 kg of barium nonylnaphthalene sulfonate (T705), 7.5 kg...

Embodiment 2

[0037] 1) 300 kg of hydroisomerization 500SN, 225 kg of bright stock 150BS, 50 kg of trimethylolpropane fatty acid ester (V40=67.2mm 2 / s), 50 kg polymethacrylate 8-450 (tackifier), 100 kg ethylene propylene copolymer oil (T612C) (tackifier), 160 kg No. 80 microcrystalline wax (thickener) together Add it into the reaction kettle, heat and stir to raise the temperature to 95°C, and stir at constant temperature for 30 minutes to melt the microcrystalline wax, then raise the temperature to 115°C, vacuumize to -0.08MPa, and keep constant temperature and constant vacuum for 1.5 hours to dehydrate.

[0038] 2) Add 3 kg of phenyl-α-naphthylamine (T531), 2 kg of 2,6-di-tert-butyl-p-cresol (T501), 20 kg of oily potassium borate (T361), 30 kg of melamine cyanurate, 20 kg of polytetrafluoroethylene superfine powder, stirred and mixed for 15 minutes to melt the solid additive, then added 0.5 kg of benzotriazole derivatives (T551), 30 kg of barium dinonylnaphthalenesulfonate (T705), 10 kg ...

Embodiment 3

[0041] 1) 120 kilograms of hydroisomerization 500SN, 455 kilograms of bright stock 150BS, 50 kilograms of trimethylolpropane fatty acid ester (V40=19.4mm 2 / s), 20 kilograms of polymethacrylate 8-450 (tackifier), 60 kilograms of polyisobutylene PB2400 (tackifier), 90 kilograms of No. 90 microcrystalline wax (thickener), 60 kilograms of polyethylene wax ( thickener) into the reaction kettle together, heat and stir to raise the temperature to 105°C, and stir at constant temperature for 60 minutes to melt the microcrystalline wax and polyethylene wax, then raise the temperature to 125°C, vacuumize to -0.08MPa, and maintain constant temperature and constant vacuum for dehydration 3 hours.

[0042] 2) Add 5 kilograms of alkyl diphenylamine (T534), 30 kilograms of oily potassium borate (T361), 50 kilograms of melamine cyanurate, and 30 kilograms of polytetrafluoroethylene superfine powder in sequence, stir and mix for 15 minutes to melt the solid additive, and then Add 0.5 kg of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com