Crankshaft decoupler

A technology for separators and drive shafts, which is applied in the direction of couplings, clutches, slip couplings, etc., and can solve the problems of reduced durability of auxiliary drive components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

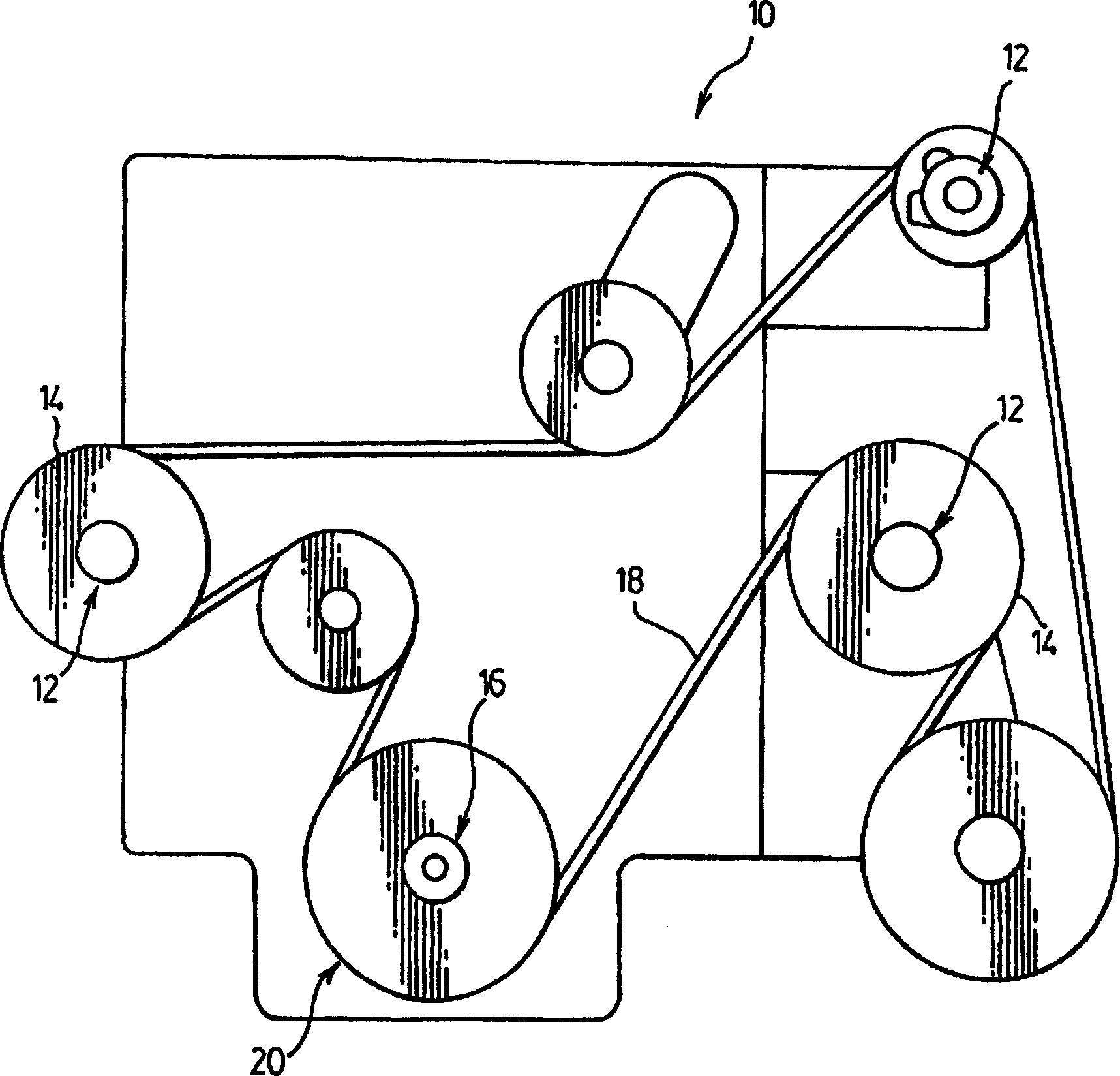

[0020] refer to figure 1 , internal combustion engines for automobiles are generally denoted by 10. Engine 10 includes a number of belt-driven accessories 12 such as alternators, compressors, and the like. A pulley 14 is operably coupled to each belt drive accessory 12 for driving the component 12 by rotation of the pulley 14 . Engine 10 also includes a crankshaft 16 that generally provides a mechanical torque output resulting from operation of engine 10 . An endless serpentine belt 18 is mounted around the pulley 14 of each belt driven attachment 12 . The belt 18 is driven in the drive direction by the rotation of the crankshaft 16 , which causes the pulley 14 to rotate. A crankshaft torque adjuster or decoupler assembly 20 is operably coupled between the crankshaft 16 and the belt 18 .

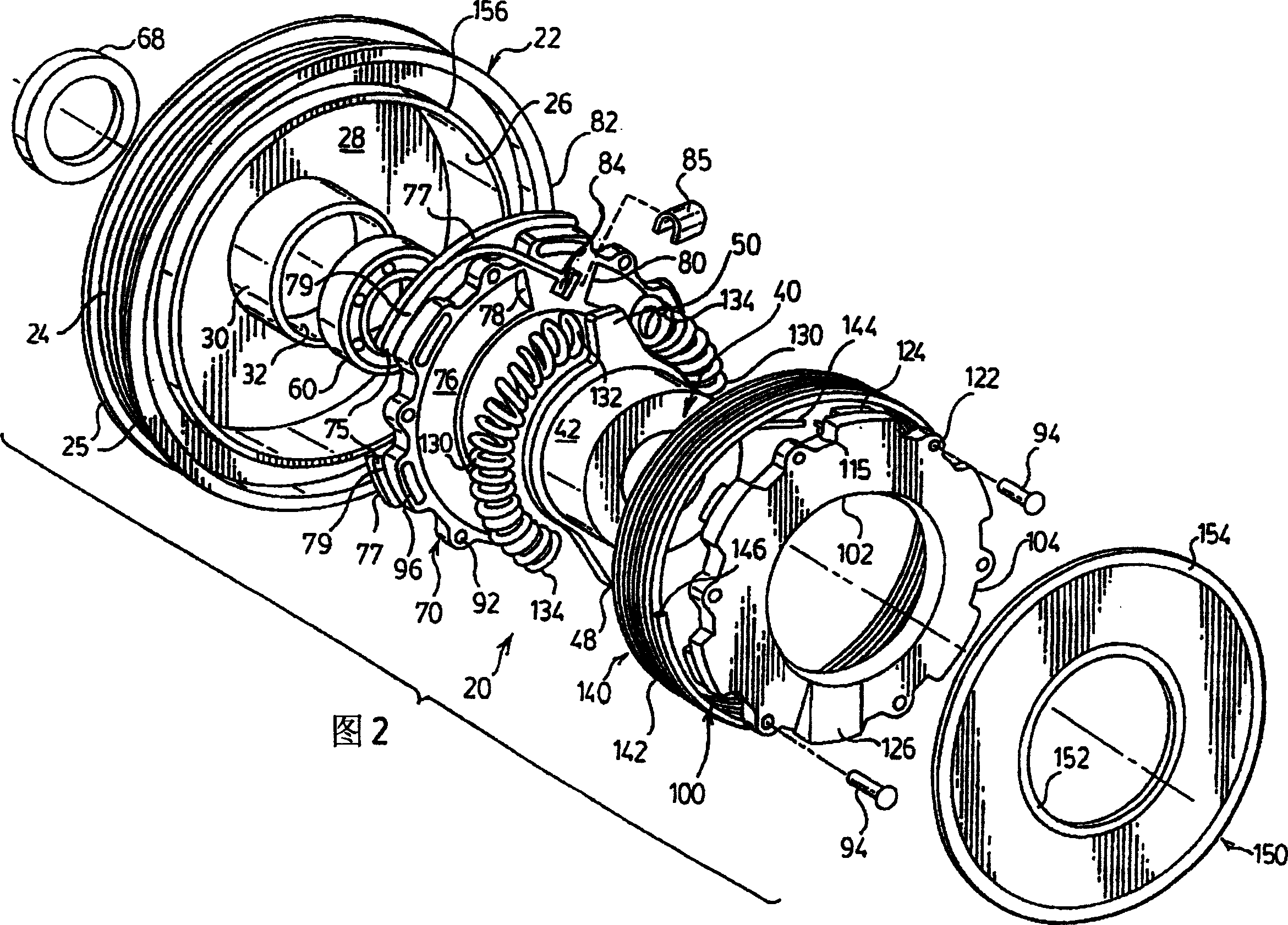

[0021] Referring to FIG. 2, the separator assembly 20 is shown in exploded view and includes an output pulley 22 having an annular outer track 24 defined by a pair of spaced apart, raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com