Supervised Autonomous Robotic System for Complex Surface Inspection and Processing

a robotic system and complex surface technology, applied in the direction of process control, process and machine control, program control, etc., can solve the problems that environmental and robotic constraints also significantly affect the types of algorithms used, and achieve the effect of accurately planning and modulating the surface process and efficiently generating high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

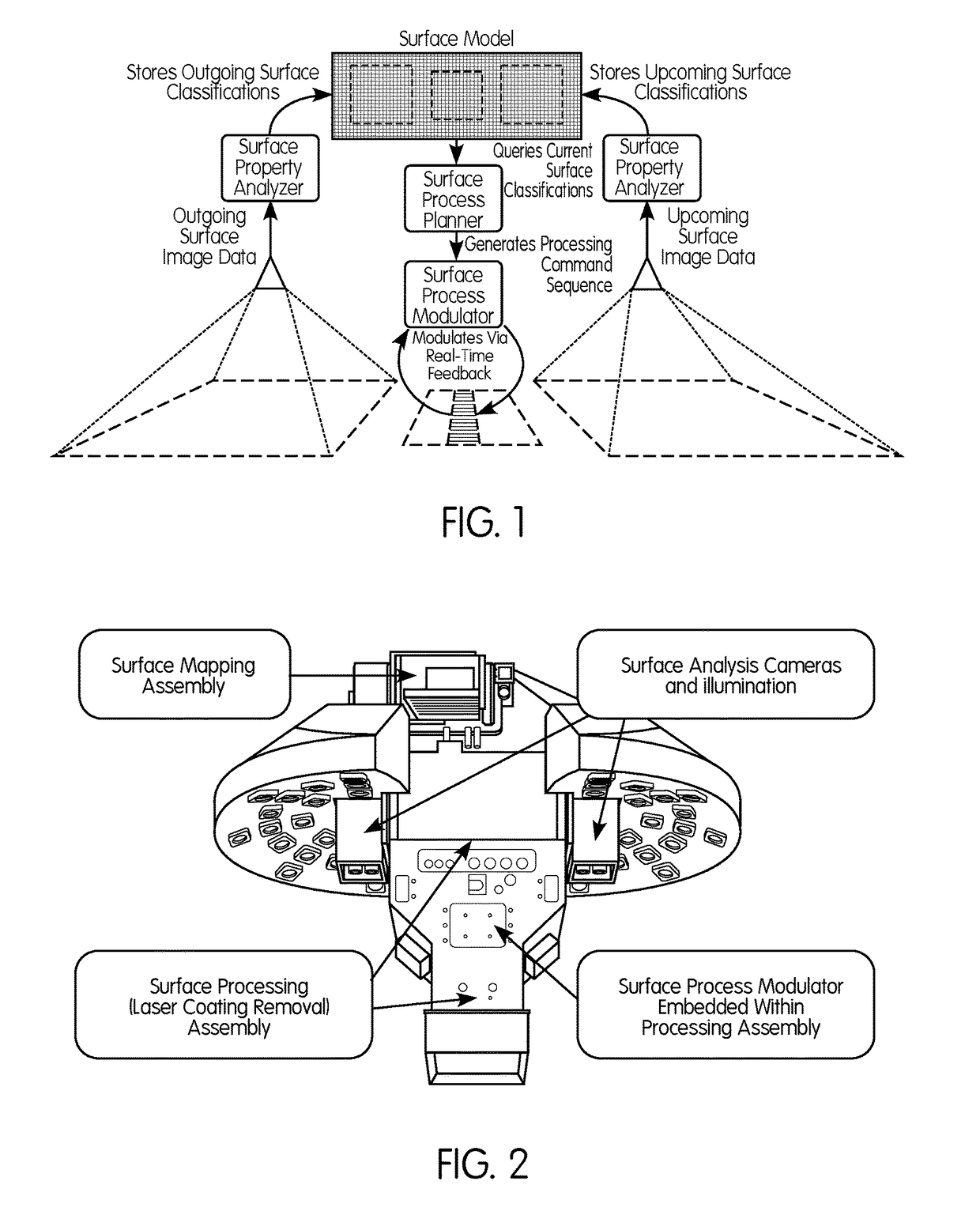

[0039]In one embodiment, the system can maneuver two machine vision components and a surface processing device over the surface of a three-dimensional object. The vision system is meant to gather sufficient data about the surface passing beneath the processing point to accurately plan for and modulate the surface process to efficiently generate high-quality results. In the case of the currently-implemented system, the surface processing device is, in one example, a high-power laser scanner, originally designed for laser welding, which is used to remove coatings from aeronautical surfaces, and the vision components estimate both the present state of the surface, i.e., where there remains coating to be stripped, and the distance and orientation of the surface relative to the aforementioned high-power laser scanner

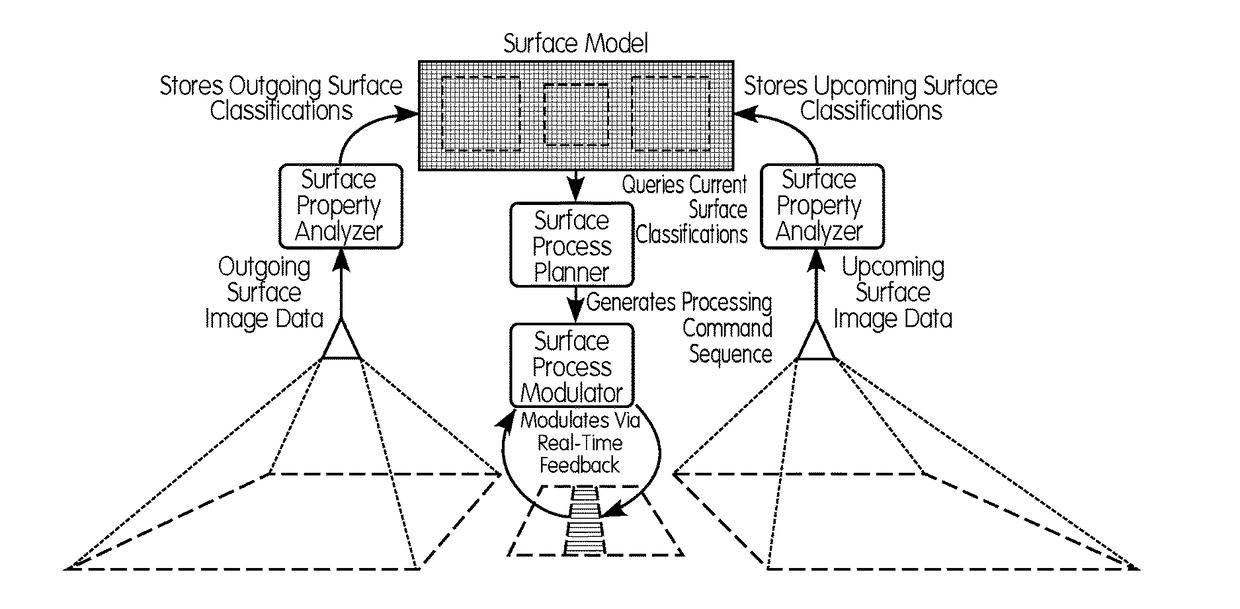

[0040]The central use case of continuous surface processing is captured in FIG. 1, showing the principal collaborations between five critical system components and the target...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com