Simplified baffle layer suitable for IBAD-MgO (ion beam assisted deposition-magnesium oxide) growth on metal substrate and preparation method thereof

A metal baseband and barrier layer technology, which is applied in the direction of metal material coating process, coating, superimposed layer plating, etc., can solve the problems of increasing the cost of the target material, the cost of the precursor solution, increasing the preparation time, increasing the cost of equipment, etc., to achieve The process parameters are easy to control, the preparation method is simple, and the effect of reducing the number of layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

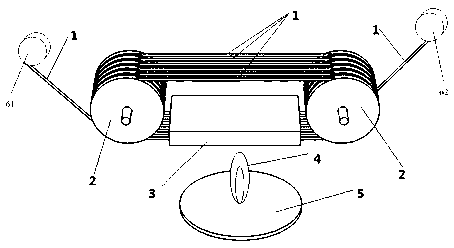

[0071] Using multi-channel laser coating technology to quickly prepare a single YAlO barrier layer on a metal substrate, the method includes the following steps:

[0072] Step 1. Install the YAlO oxide target prepared by high-temperature sintering on the target holder in the cavity;

[0073] Step 2. Wrap the metal base tape in a multi-channel pulsed laser coating system;

[0074] Step 3. Close the door of the coating system and evacuate to the required vacuum degree of 1×10 -6 Torr;

[0075] Step 4. Introduce oxygen, the mass flow meter controls the oxygen flow rate to 10 sccm, and the gas pressure is adjusted to 1×10 by the molecular pump gate valve. -3 Torr;

[0076] Step 5. Start the laser target rotation and scanning system, start the excimer laser, adjust the laser energy to 200mJ, and the laser frequency to 180Hz;

[0077] Step 6. After the air pressure, laser energy, and laser frequency are stable, turn on the laser optical path switch to start the pre-sputtering pr...

Embodiment 2

[0081] Using multi-channel laser coating technology to quickly prepare a single YAlO barrier layer on a metal substrate, the method includes the following steps:

[0082] Step 1. Install the YAlO oxide target prepared by high-temperature sintering on the target holder in the cavity;

[0083] Step 2. Wrap the metal base tape in a multi-channel pulsed laser coating system;

[0084] Step 3. Close the door of the coating system and evacuate to the required vacuum degree of 3×10 -6 Torr;

[0085] Step 4, feed oxygen, the flow of oxygen is controlled to 15 sccm by the mass flow meter, and the air pressure of the gas is adjusted to 1×10 by the gate valve of the molecular pump -2 Torr;

[0086] Step 5. Start the laser target rotation and scanning system, start the excimer laser, adjust the energy to 350mJ, and the frequency to 100Hz;

[0087] Step 6. After the air pressure, laser energy, and laser frequency are stable, turn on the laser optical path switch to start the pre-sputter...

Embodiment 3

[0091] Using multi-channel laser coating technology to quickly prepare a single YAlO barrier layer on a metal substrate, the method includes the following steps:

[0092] Step 1. Install the YAlO oxide target prepared by high-temperature sintering on the target holder in the cavity;

[0093] Step 2. Wrap the metal base tape in a multi-channel pulsed laser coating system;

[0094] Step 3. Close the door of the coating system and evacuate to the required vacuum degree of 6×10 -6 Torr;

[0095] Step 4, feed oxygen, the flow of oxygen is controlled to 20 sccm by the mass flow meter, and the air pressure of the gas is adjusted to 2×10 by the gate valve of the molecular pump -1 Torr;

[0096] Step 5. Start the laser target rotation and scanning system, start the excimer laser, adjust the laser energy to 450mJ, and the frequency to 40Hz;

[0097] Step 6. After the air pressure, laser energy, and laser frequency are stable, turn on the laser optical path switch to start the pre-sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com