Laser stereo shaping method for preparing buccal metal prosthesis

A laser three-dimensional forming and prosthesis technology, applied in the field of stomatology or biomedical engineering, can solve the problems of low material utilization rate, simple forming shape, long processing cycle, etc., achieving huge economic and social benefits, saving materials, The effect of improving the degree of automation and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

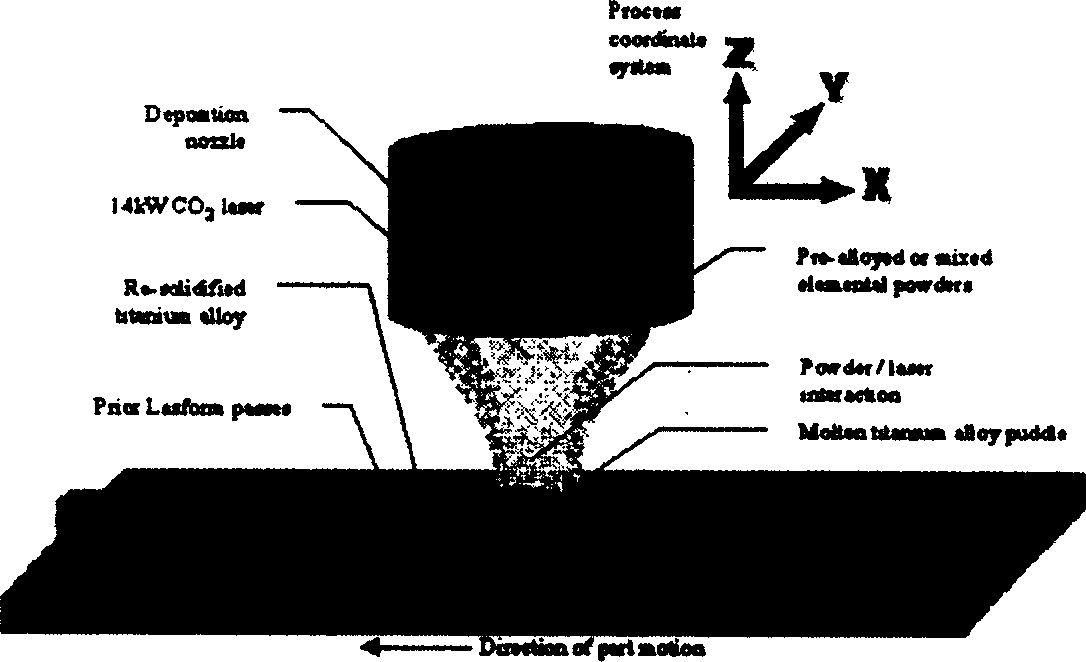

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and the embodiments given by the inventor. 5.1 Experimental equipment

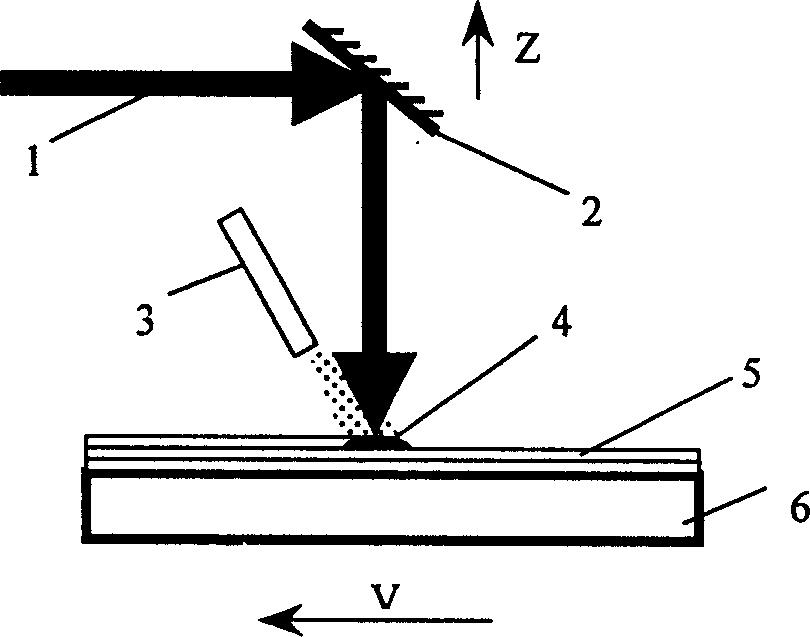

[0015] see figure 2 , The laser processing experimental equipment includes a laser 1, a reflective focusing mirror 2, a powder feeder 3, a substrate 5, a molten pool 4, and a CNC workbench 6. The data acquisition equipment includes Taiwan-made four-axis CNC laser scanning system and IntelPIV2.0G computer. Software: SURFACER 10.5, SDBC (Structural Dynamics Research Corporation) company; Cloud Date Process software, developed and designed by Xi'an Jiaotong University to process point cloud data; MIMICS software, Belgium Materialize company; RP daba software, designed by Xi'an Jiaotong University, slices CAD The model is converted to STL format software. 5.2 Experimental materials

[0016] Rene95 alloy powder is selected, and its composition is shown in Table 1. The particle size is -200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com