Energy dissipation and shock absorption type fabricated beam-column joint

A beam-column joint and assembly technology, which is applied in the direction of earthquake resistance, building types, protective buildings/shelters, etc., can solve the problem of unfavorable joint connection with small stiffness of angle steel, the inability to realize strong joints and weak members, energy consumption and friction of steel plate deformation The energy consumption mechanism is difficult to achieve the effect of optimizing the force transmission mechanism, avoiding local damage, and dissipating seismic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

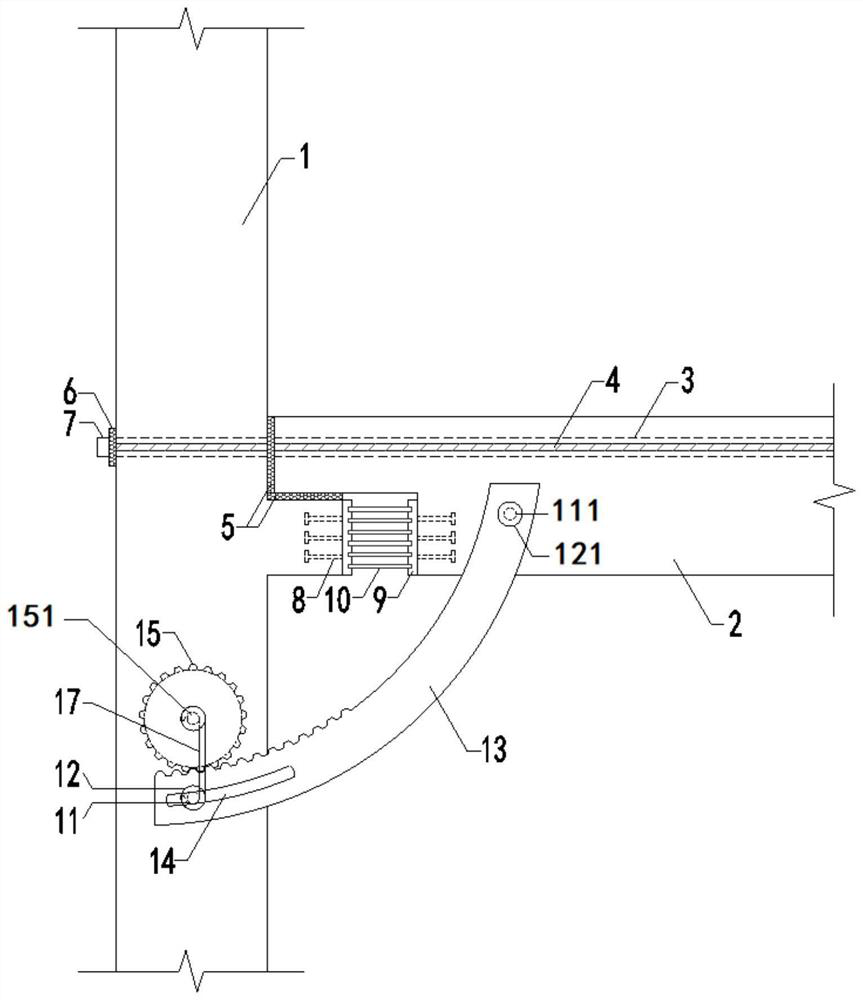

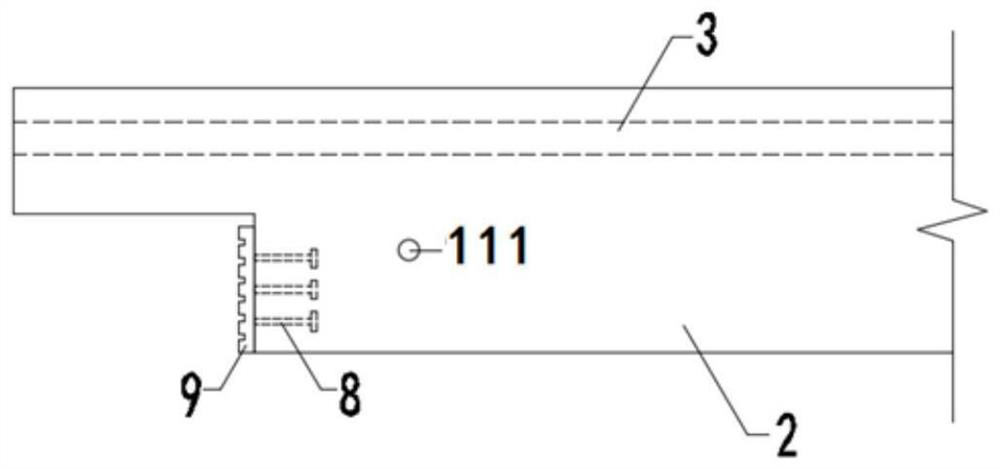

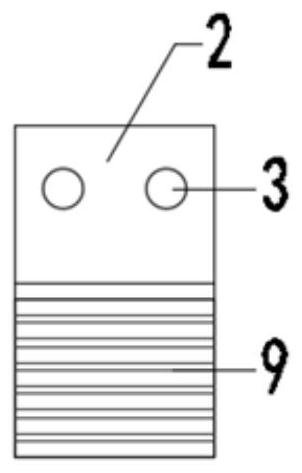

[0047] refer to figure 1 , an energy-dissipating and shock-absorbing fabricated beam-column joint; refer to Figure 2 to Figure 7 , including vertical prefabricated column 1 and horizontal prefabricated beam 2, prefabricated column 1 and prefabricated beam 2 are connected; refer to Figure 8 , a frictional energy dissipation assembly is set between the two, and the frictional energy dissipation assembly includes a gear arm 13 and a gear composite 15; refer to Figure 9 At least one of the prefabricated column 1 and the prefabricated beam 2 is equipped with a gear composite 15, the gear composite 15 meshes with the rack, and the rack is arranged on the gear arm 13; the gear arm 13 is provided with a limit groove 14, the limit groove A position-fixed stop pin 12 is set in 14 . That is, the gear arm 13 and the gear compound 15 are effectively meshed by setting the frictional energy dissipation components. When the prefabricated beam 2 is vertically deformed, the gear arm 13 dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com