PLZT micron seed crystal, preparation method thereof and application of PLZT micron seed crystal in induction of ceramic growth

A technology of microcrystalline and ceramics, applied in chemical instruments and methods, inorganic chemistry, titanate, etc., can solve the problems of high energy consumption of materials, limited application range, high threshold electric field, etc., and achieve good dispersion, excellent material performance, and threshold The effect of electric field reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

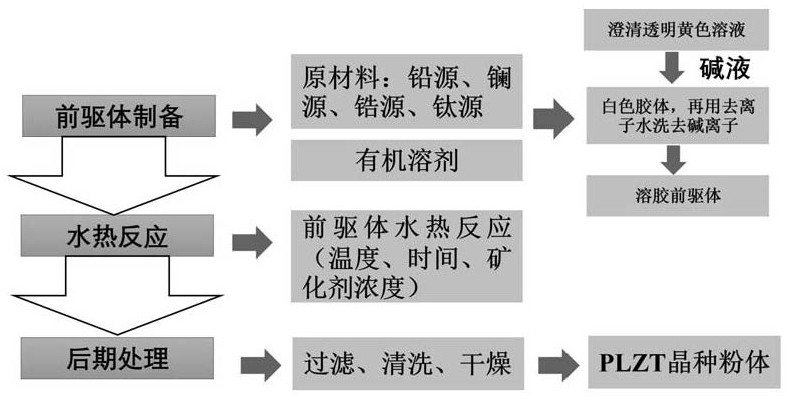

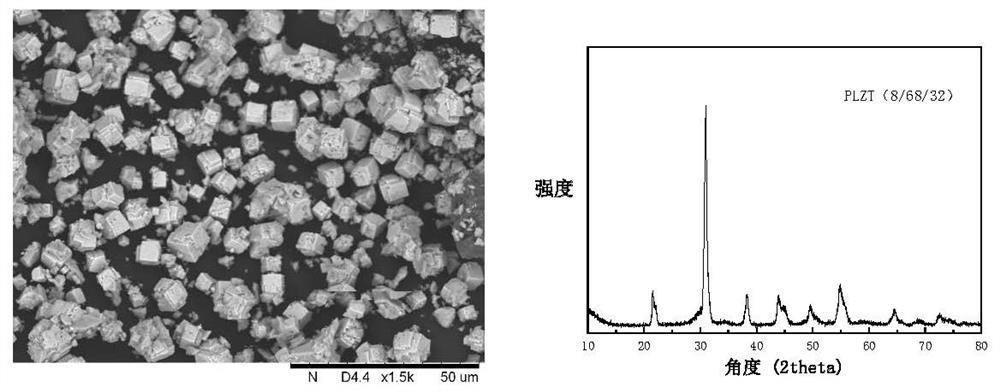

[0045] In the present invention, the preparation method of PLZT micro-seed is gel-hydrothermal method, which mainly includes three steps: preparation of precursor, hydrothermal reaction and post-treatment. The generated PLZT micron seeds are pure perovskite phase, and the appearance is cubic particles, which are flat and uniform, and have good dispersion. The purity of the powder obtained after repeated separation and filtration is about 100%.

[0046] In the present invention, the preparation method of micron-seed-induced-growth electronically-controlled light-scattering ceramics may include: weighing, ball milling and mixing, drying, sieving, granulating, molding, and oxygen-passed hot-press sintering. Wherein the PLZT micron seeds are added in the mixing stage of ball milling.

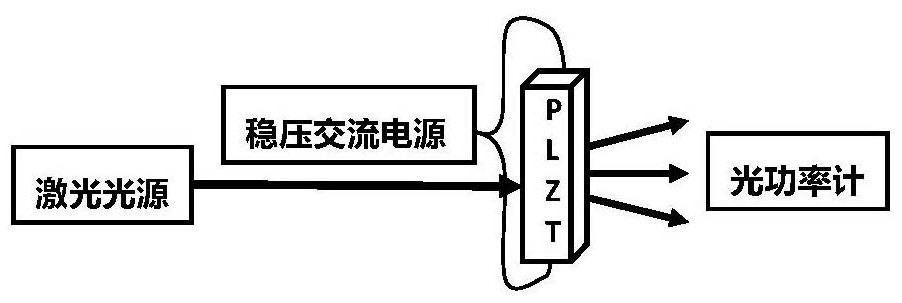

[0047] After cutting and polishing the electronically controlled light-scattering ceramics induced by micron seed crystals, electrodes are made on both ends of the sample perpendicular to the light...

Embodiment 1

[0051] According to Pb 1-x La x (ZryTi 1-y ) 1-x / 4 o 3 , wherein x=0.08, y=0.68 (referred to as PLZT (8 / 68 / 32)) batching, lead ethylate, lanthanum isopropoxide, zirconium n-propoxide, tetrabutyl titanate are weighed according to stoichiometric ratio (solute) , dissolved in 2 parts (1 part means adding 100g of solute to 100mL solution, and so on) in ethylene glycol methyl ether solution, and stirred until the solution was clear and transparent. Then add 3 parts of ammonia water (about 14M) to form a white colloid. The gel obtained by washing and filtering with deionized water is the seed crystal precursor. Then add 2M mineralizer KOH to the precursor, and hydrothermally treat it at 230°C for 16h; after hydrothermal synthesis, the resulting product is repeatedly washed with deionized water and filtered, and dried at 90°C for 24h to obtain PLZT micron seeds Powder. image 3 Morphology and XRD phase structure for the preparation of hydrothermal micro-seeds.

preparation Embodiment 2

[0053] According to Pb 1-x La x (ZryTi 1-y ) 1-x / 4 o 3 , wherein x=0.08, y=0.68 (referred to as PLZT (8 / 68 / 32)) batching, lead ethylate, lanthanum isopropoxide, zirconium n-propoxide, tetrabutyl titanate are weighed according to stoichiometric ratio (solute) , dissolved in 2 parts of ethylene glycol methyl ether solution, and stirred until the solution was clear and transparent. Then add 3 parts of ammonia water (about 14M) to form a white colloid. The gel obtained by washing and filtering with deionized water is the seed crystal precursor. Then add 2M mineralizer KOH to the precursor, and hydrothermally treat it at 230°C for 24h; after hydrothermal synthesis, the product obtained is washed repeatedly with deionized water and filtered, and dried at 90°C for 24h to obtain PLZT micron seeds Powder. Figure 4 Morphology and XRD phase structure for the preparation of hydrothermal micro-seeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com