Automatic controller for laser coating and powder feeding system

An automatic control device and laser cladding technology, applied in non-electric variable control, flow control using electric devices, flow control, etc., can solve the problems of lack of automatic control device, inability to detect and adjust powder feeding amount in real time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

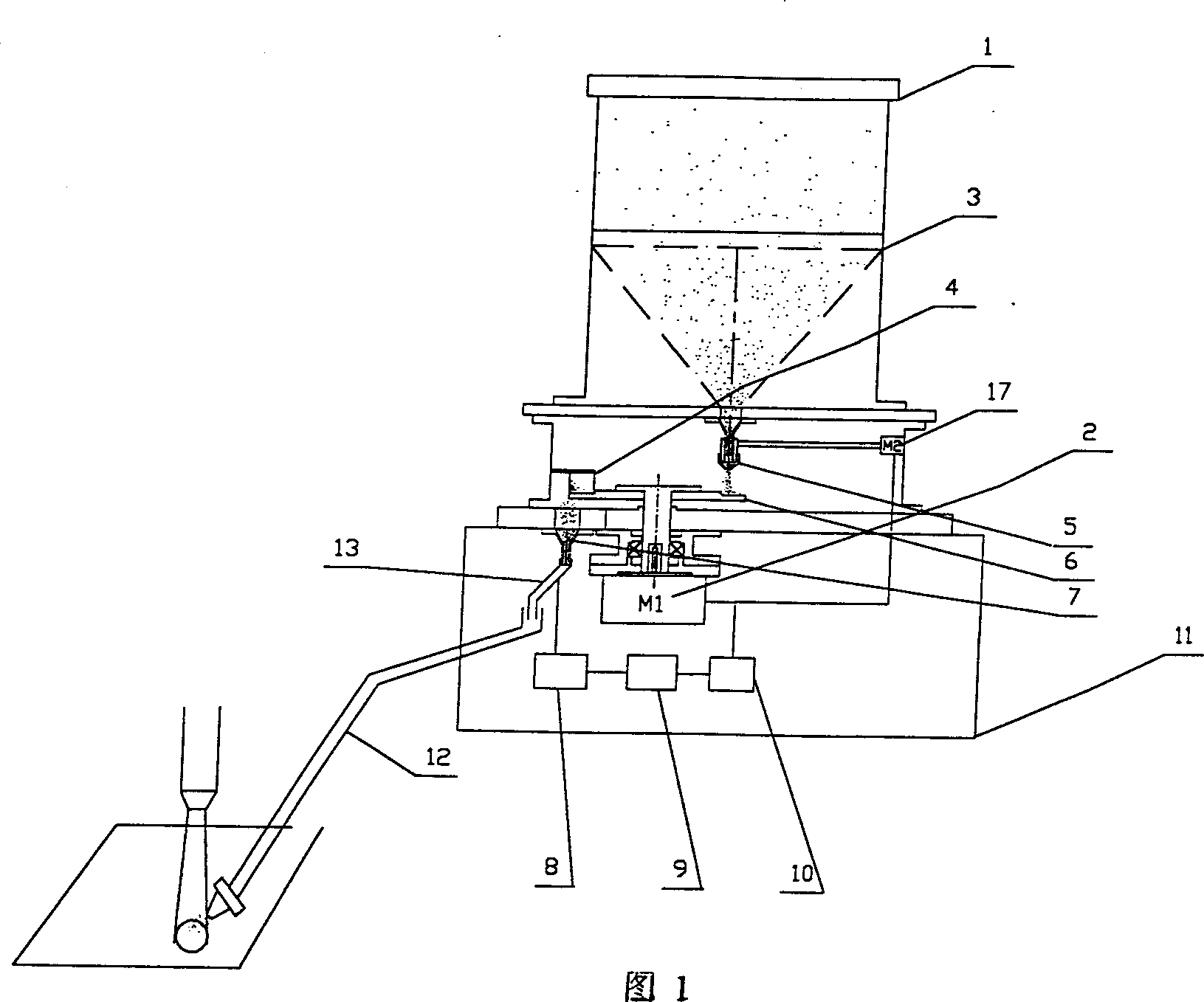

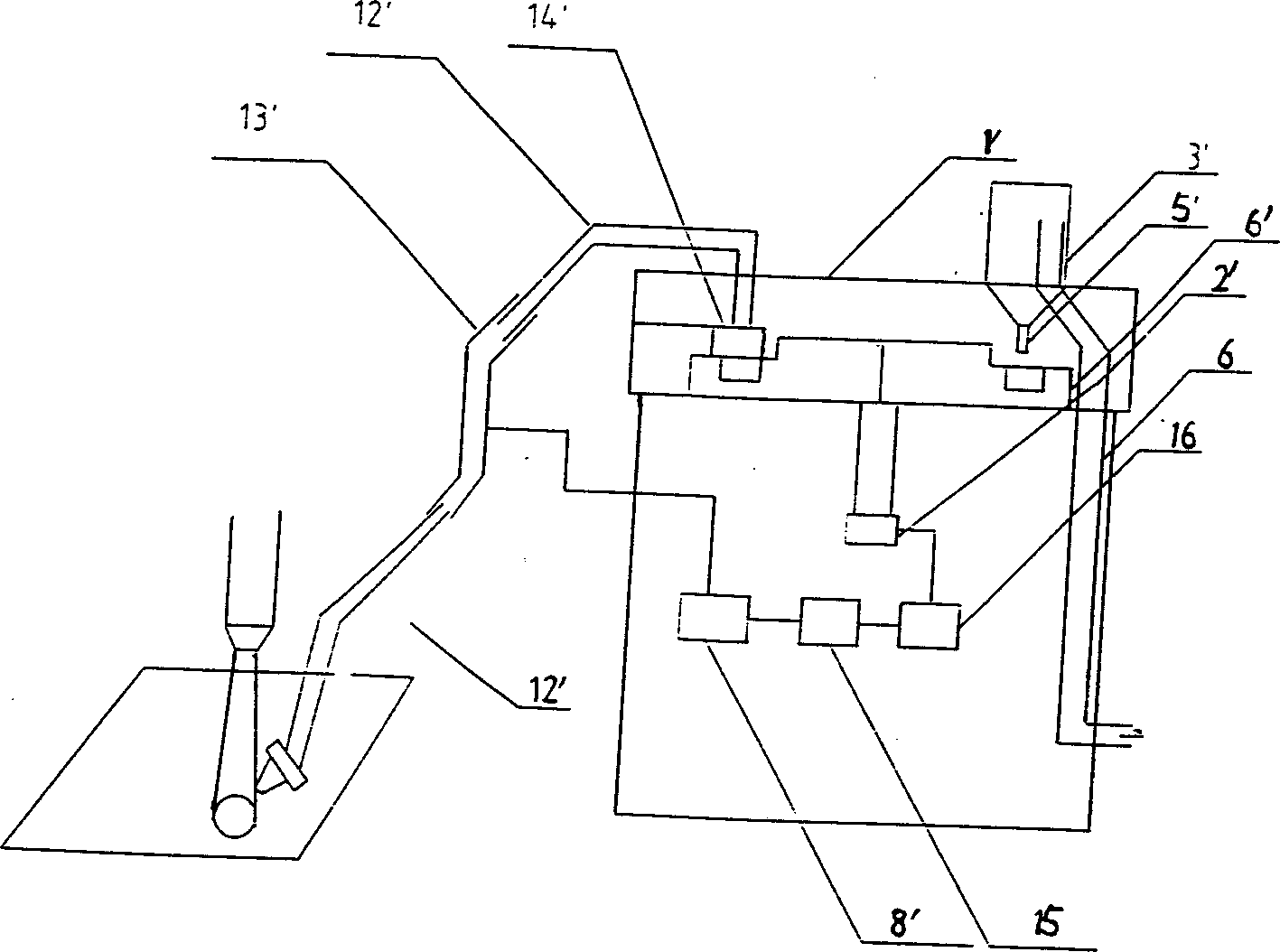

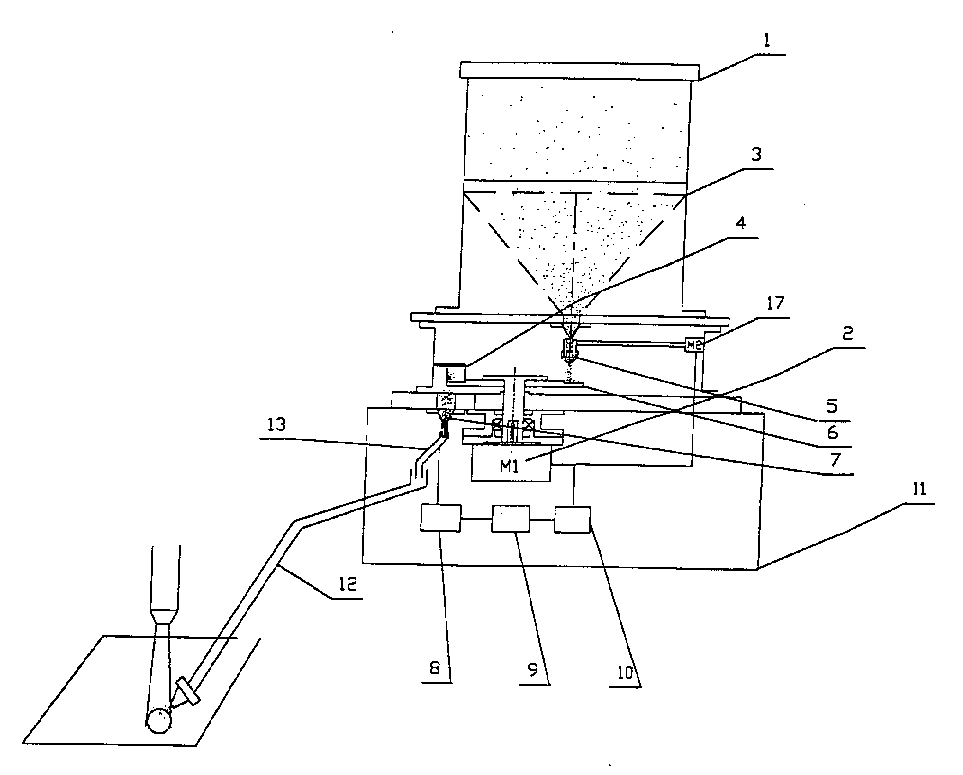

[0012] In FIG. 1 , the control motor 2 in the scraper powder feeder 1 drives the turntable 6 to rotate, so that the powder in the powder storage funnel 3 flows continuously onto the turntable 6 through the nozzle 5 . When the plane turntable loaded with powder turns to the scraper 4, the powder synchronously moving with the plane turntable 6 is blocked and accumulates at the scraper, and when the amount of accumulation reaches a certain level, it continues to fall into the funnel 7 along the edge of the plane turntable , and form a powder flow. The powder falling into the funnel is sent into the laser action area through the conveying pipeline 12 under the action of gravity and auxiliary gas. In the present invention, the measuring pipeline 13 is installed between the outlet of the funnel 7 and the inlet of the delivery pipeline 12 (it can also be installed between the two sections of the delivery pipeline), and the weighing pressure sensor 8 (also can be a micro pressure sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com