Light beam movement track control device for laser processing

A motion trajectory and control device technology, which is applied in the field of beam motion trajectory control devices for laser processing, and can solve problems such as small deflection amplitude, unsuitable processing, and small modulation motion range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

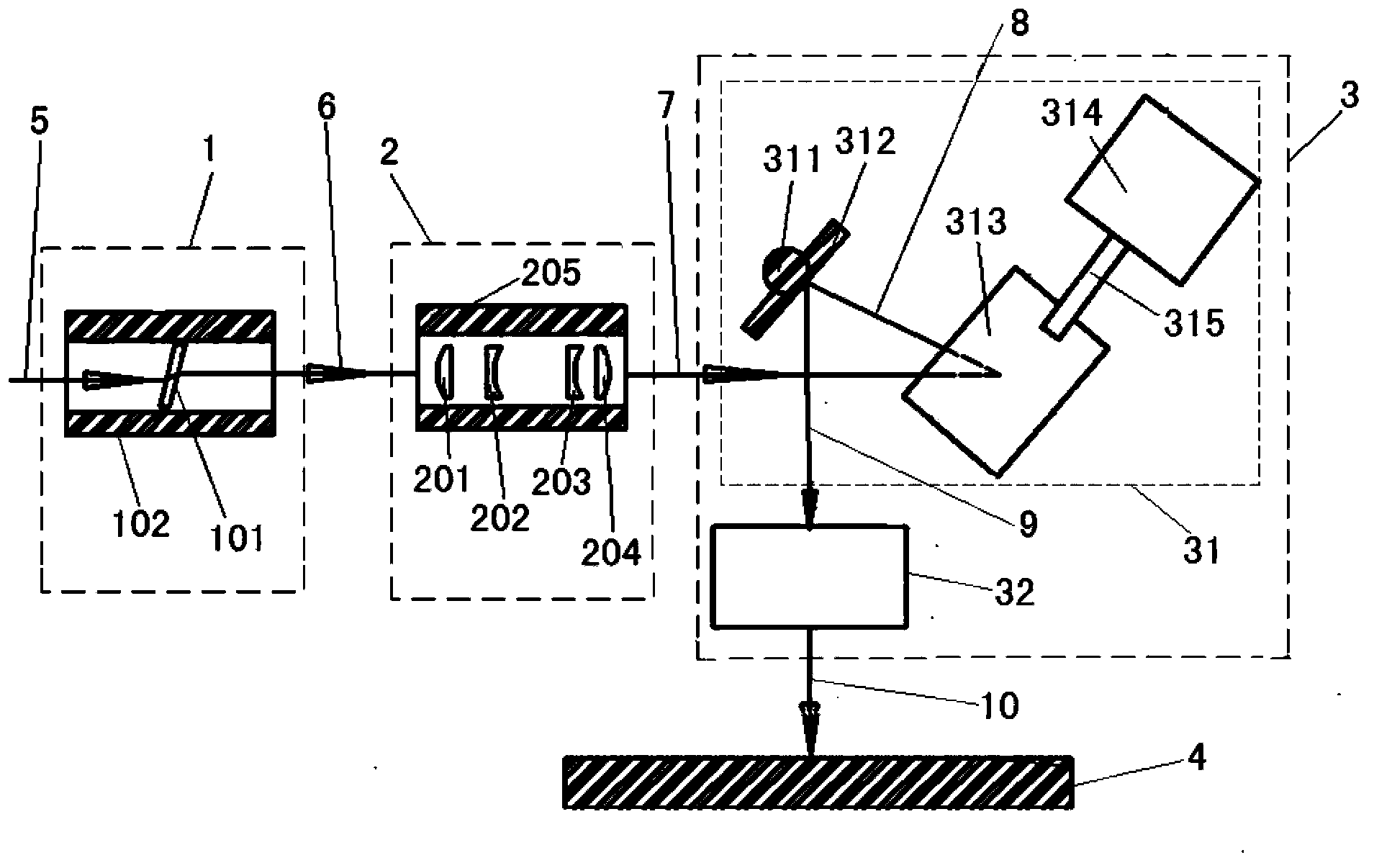

[0046] figure 1 Schematic diagram of the device structure for laser drilling through holes in copper foil, such as figure 1 As shown: the device for copper foil laser drilling through holes includes a beam transmission azimuth control module 1 , a beam movement trajectory imaging amplification module 2 and a laser focusing and focus switching module 3 .

[0047] The beam transmission azimuth control module 1 is a beam rotation modulation unit, the beam rotation modulation unit includes a beam rotation modulation sub-unit, the beam rotation modulation sub-unit includes a rotating transmission optical element and a rotating transmission optical element for driving the rotating motion drive unit. The rotating transmission optical element is a rotating flat quartz glass 101. The refractive index of the rotating flat quartz glass 101 is 1.35 to 3, preferably 1.45, and the thickness is 6 mm. Larger, the larger the beam rotation diameter. The driving device is an air-floating holl...

Embodiment 2

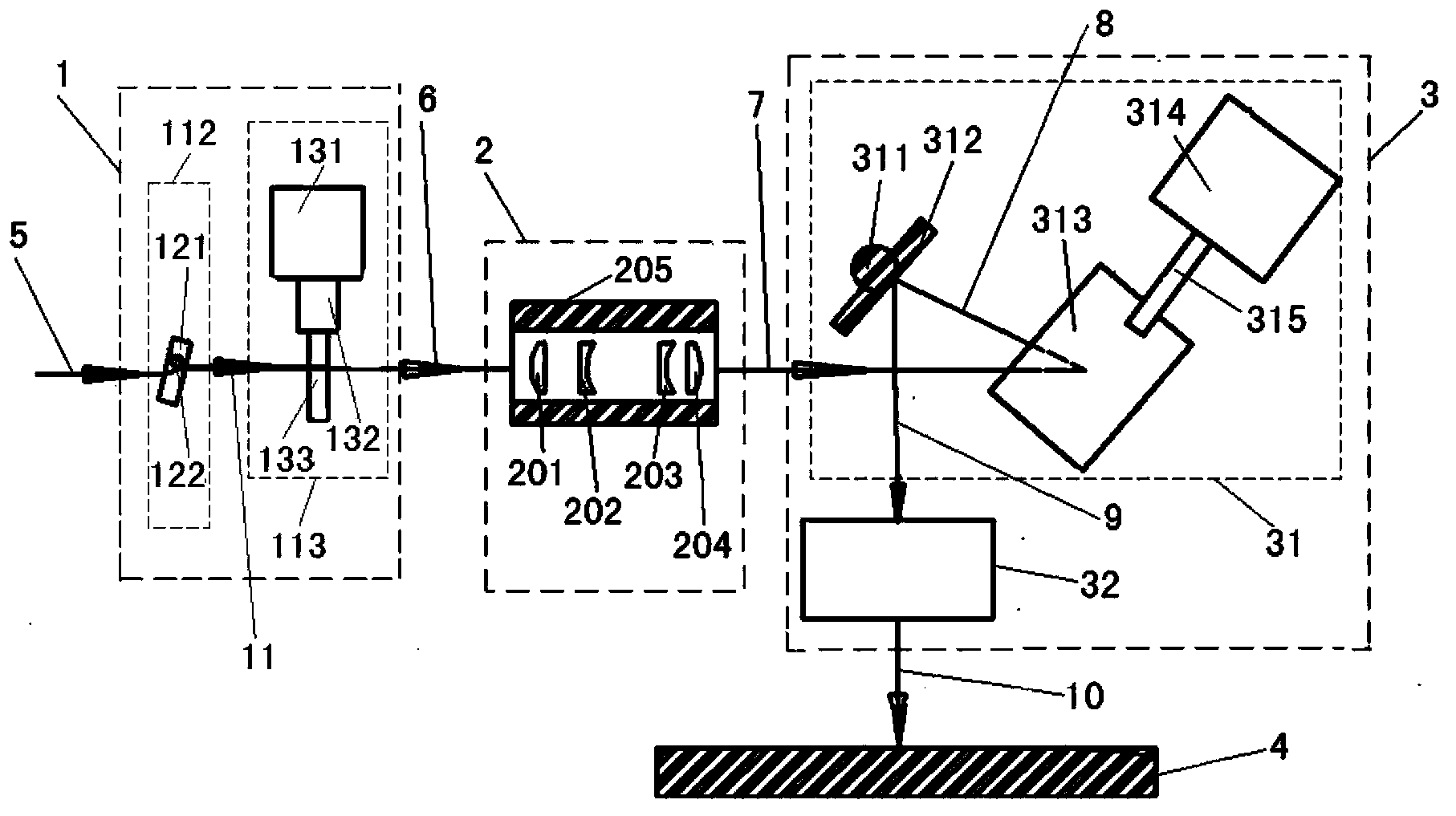

[0069] figure 2 Schematic diagram of the device structure for laser milling blind grooves of aluminum nitride ceramics, such as figure 2 As shown: the device for laser milling blind slots on aluminum nitride ceramics includes a beam transmission azimuth control module 1 , a beam trajectory imaging amplification module 2 and a laser focusing and focus switching module 3 . The structures of the beam movement trajectory imaging amplification module 2 and the laser focusing and focus switching module 3 in this embodiment are the same as those in the first embodiment.

[0070] The beam transmission azimuth control module 1 includes a beam offset modulation unit, which includes two serially connected beam offset subunits, namely a first beam offset unit 112 and a second beam offset unit 113 . The first beam shifting unit 112 includes a first flat quartz glass 121 and a first motor (not shown in the figure) for driving the first flat quartz glass 121, and the first flat quartz gla...

Embodiment 3

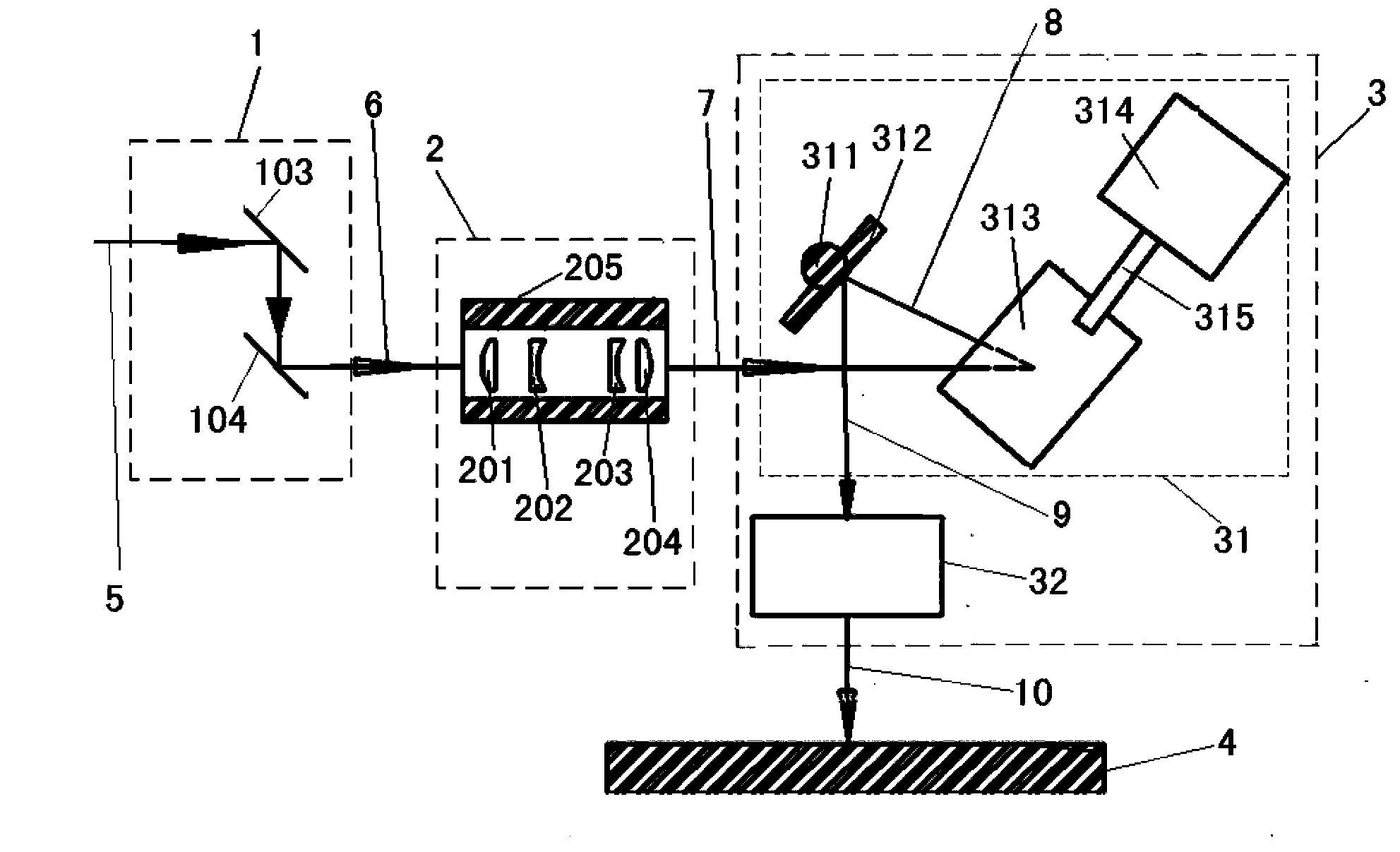

[0086] image 3 It is a schematic diagram of the device structure of embodiment 3 low-temperature co-fired ceramic laser drilling, as image 3 As shown: the device for laser drilling of low-temperature co-fired ceramics includes a beam transmission azimuth control module 1 , a beam trajectory imaging amplification module 2 and a laser focusing and focus switching module 3 . The structures of the beam movement trajectory imaging amplification module 2 and the laser focusing and focus switching module 3 in this embodiment are the same as those in the first embodiment.

[0087] The beam transmission azimuth control module 1 includes a beam offset modulation unit, which includes two series-connected beam offset subunits, namely a first beam offset unit and a second beam offset unit, the first beam offset unit The offset unit includes a first plane mirror 103 and a first piezoelectric ceramic drive system (not shown in the figure) for driving the first plane mirror 103 to move (sw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com