Flexible multi-beam laser processing head based on light field regulation and using method thereof

A laser processing head and laser processing technology, used in lasers, laser welding equipment, laser parts, etc., can solve the problems of slow processing efficiency, increased cost, complicated optical path design, etc., and achieve increased laser processing energy and wide processing applicability. , Enhance the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

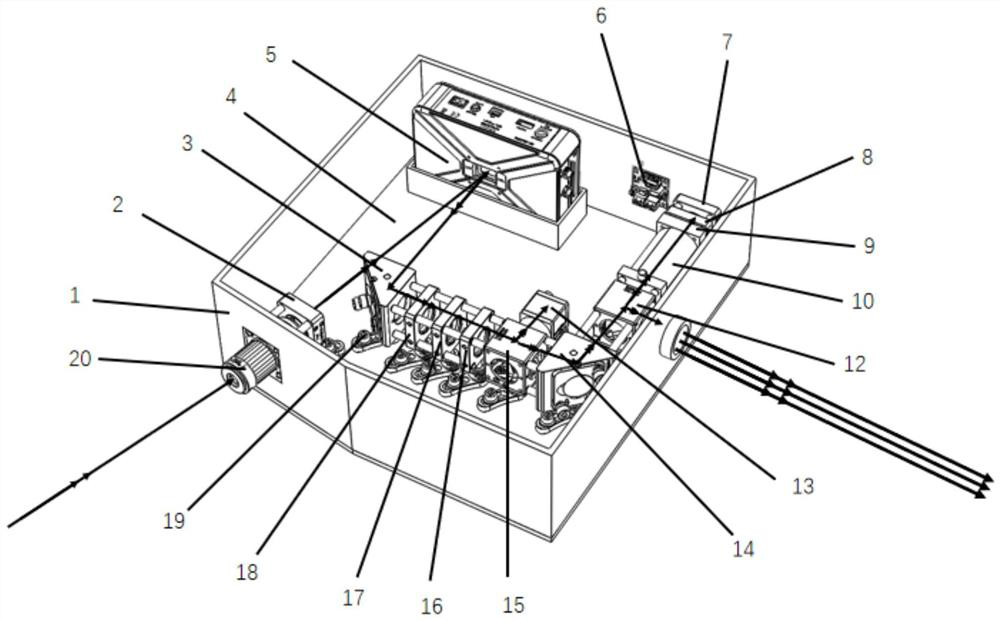

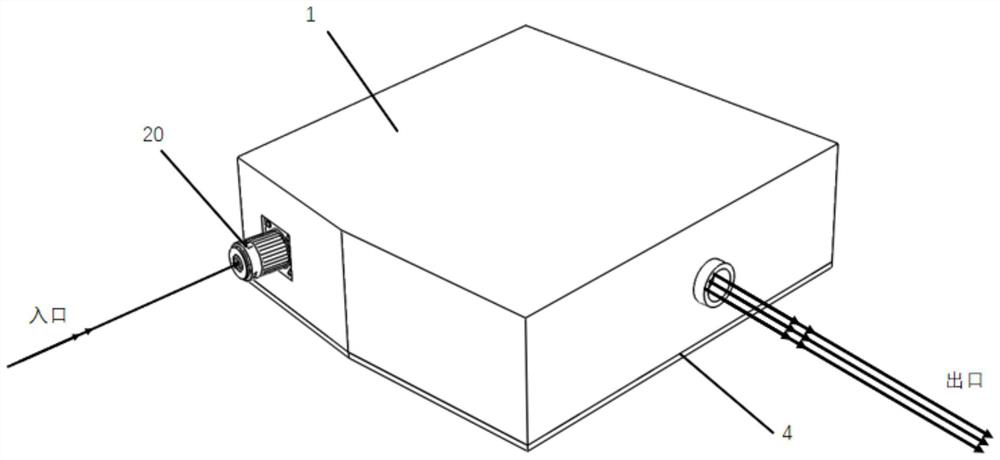

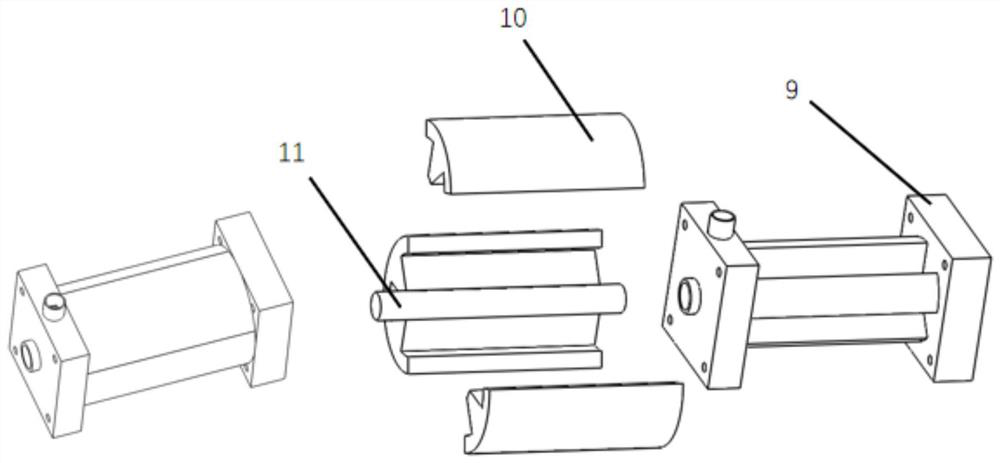

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] In order to solve the problems of single function, low processing efficiency, poor flexibility, and no feedback in the current laser processing head technology, the present invention provides a flexible multi-beam laser processing head based on light field regulation and its use method. The incident laser beam is adjusted for the light field, and the wavefront sensor is used to monitor the distribution of the light field in real time, and the power of the regulated beam is amplified to achieve a high-power preset laser light field distribution. The exit can be connected to a scanning galvanometer or a fixed The first-class laser processing system meets various laser processing needs, and can communicate with the computer through the control circuit to control and monitor laser transmission in real time, which can realize flexible laser processing with h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com