Ultraviolet-curing odorless laser-coating matt finishing paint preparation method

A UV light and odor-cleaning technology, applied in coatings, polyester coatings, epoxy resin coatings, etc., can solve problems affecting the health of production workers, residues in the paint film, volatilization into the air, etc., and achieve good curing speed and adhesion, soft gloss and scratch resistance, and the effect of improving tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

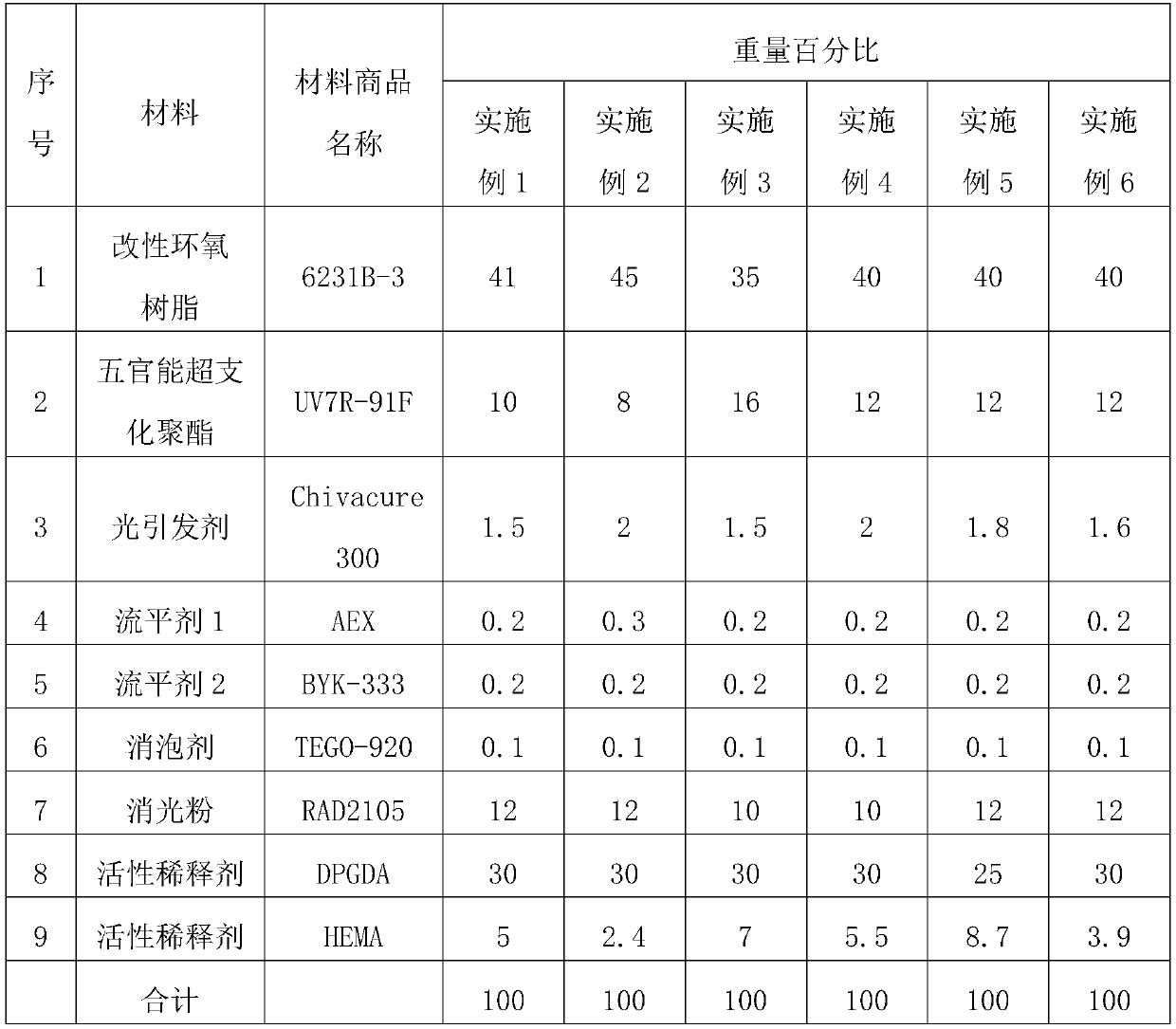

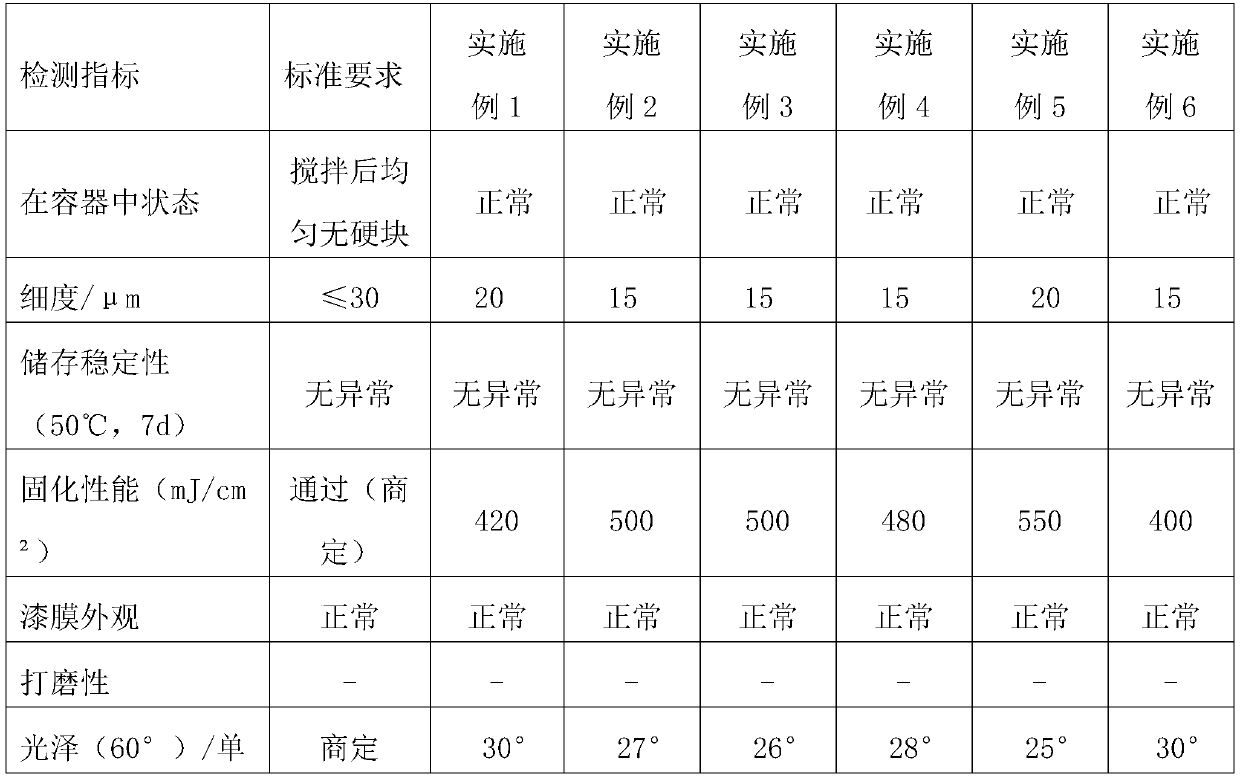

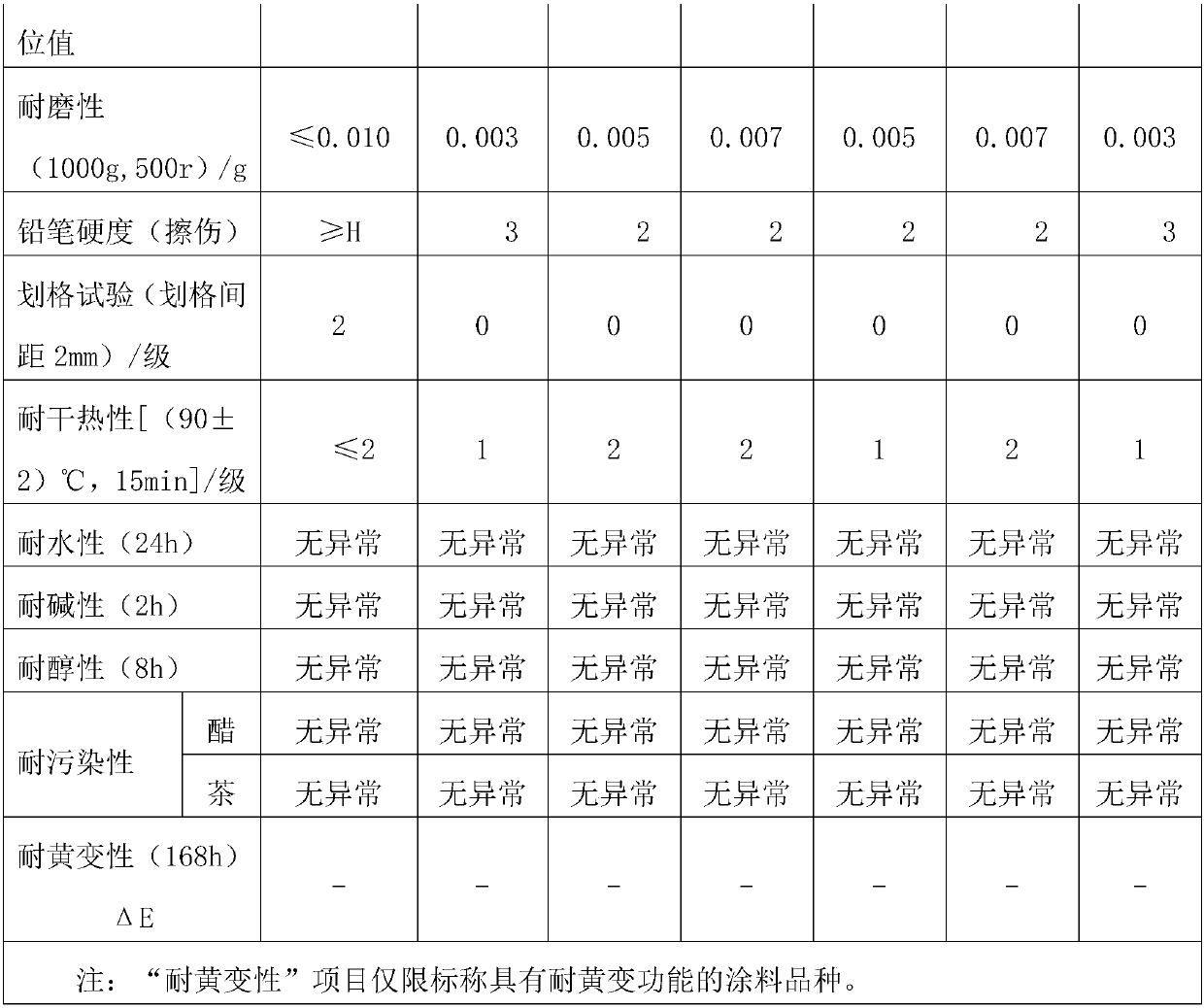

[0023] The present invention will be described in detail below in conjunction with examples, and the examples are only preferred implementation cases of the present invention, and are not limitations of the present invention.

[0024] The raw materials are operated according to the steps described in the specific preparation method above:

[0025] A. First put the resin, dispersant, and part of the active diluent in the formula into the reactor, and disperse for 20-30 minutes at a speed of 800-1200 rpm;

[0026] B. Add defoamer and leveling agent in proportion to disperse for 20 minutes at a speed of 1000-1200 rpm;

[0027] C. Throw in photoinitiator, and disperse for 10 minutes at a speed of 800-1000 revolutions per minute;

[0028] D. Add matting powder according to the proportion, and disperse for 30 minutes at a speed of 1200-1800 rpm;

[0029] E. Put in all the UV active diluents, and disperse for 15 minutes at a speed of 600-800 rpm. After passing the test, use a 300-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com