Colored film substrate and manufacturing method thereof, display panel and manufacturing method thereof, and display device

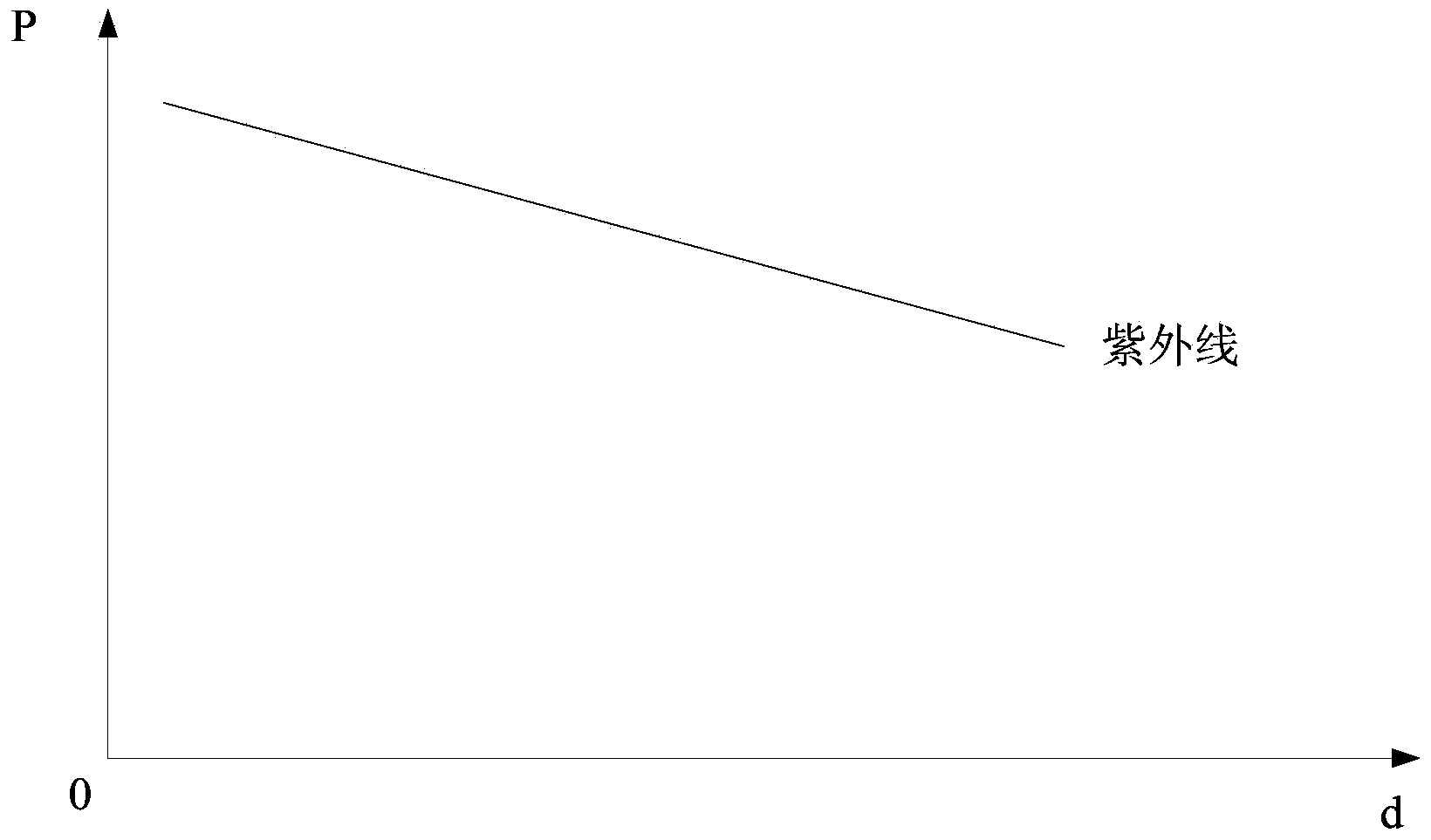

A color film substrate and color film technology, applied in the field of color film substrates and production methods, display panels and production methods, and display devices, can solve the problems of reduced curing speed and inability to effectively increase the pre-curing speed of sealing glue, and achieve Effect of improving curing speed and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

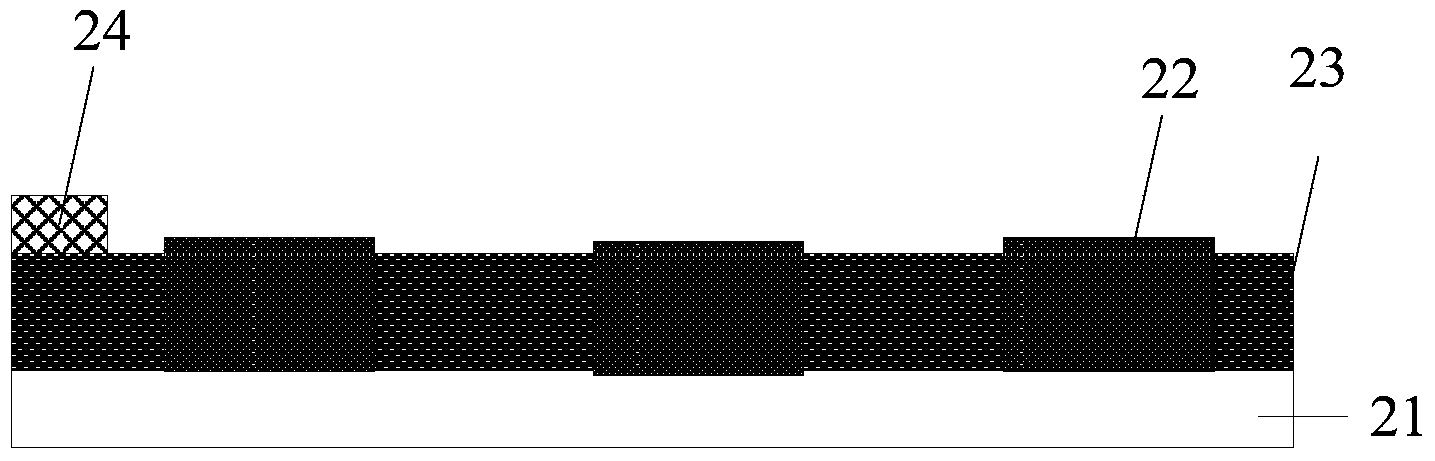

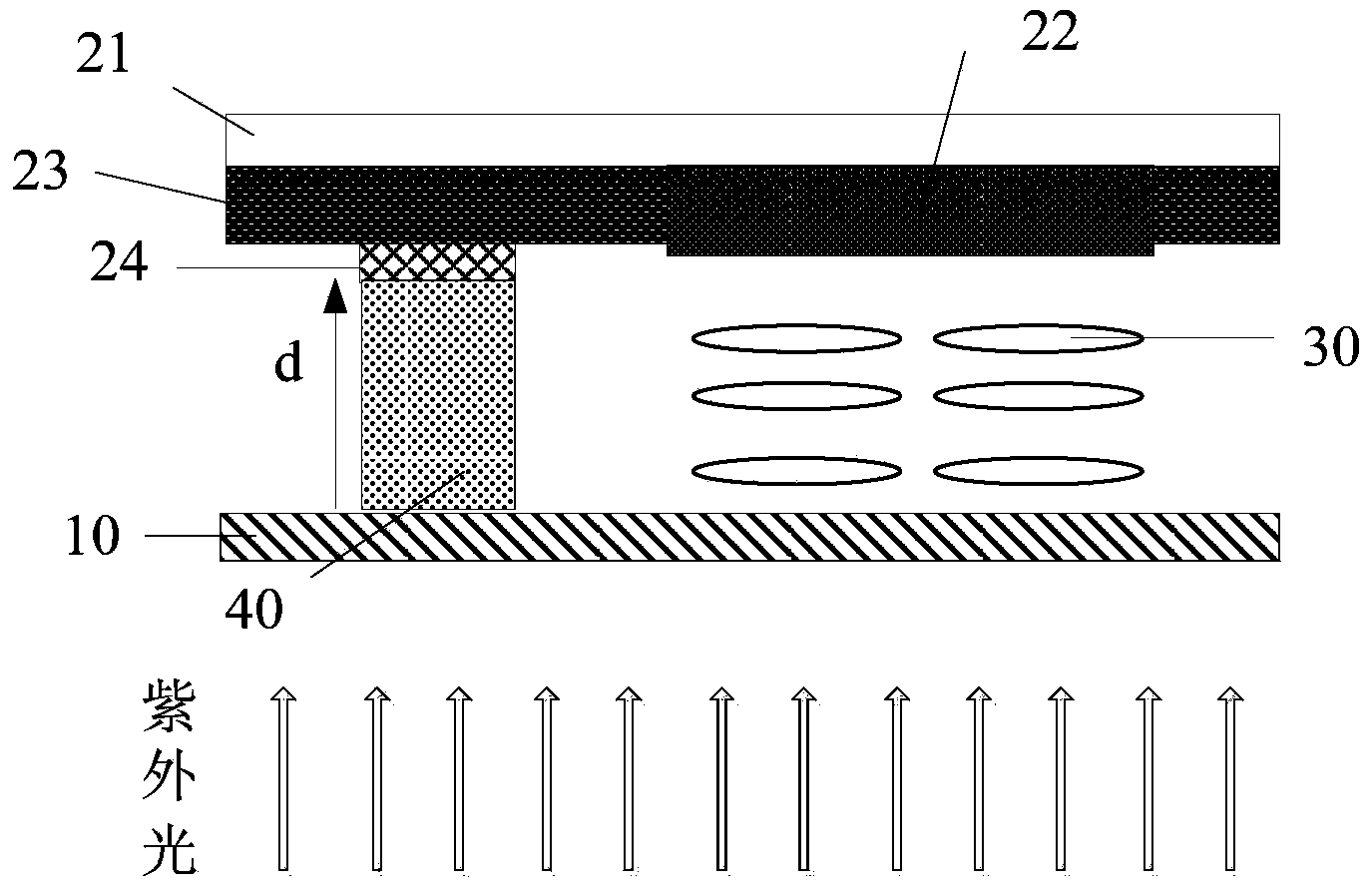

[0040] The invention provides a color filter substrate, such as figure 2 As shown, the color filter substrate includes:

[0041] The substrate 21 and the color filter layer pattern 22 and the black matrix layer pattern 23 formed on the substrate 21; the catalyst film layer pattern 24 formed on the black matrix layer pattern 23 for setting the area of the sealant, The catalyst film layer pattern 24 can increase the curing speed of the sealant when irradiated by ultraviolet light.

[0042] Here, the substrate 21, the color filter layer pattern 22, and the black matrix layer pattern 23 constitute the main body of the color filter substrate. For the specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com