UV (Ultraviolet)-compound laser coating composition

A UV-composition technology, applied in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of not meeting production requirements, affecting the effect of laser patterns, and the laser patterns are not heat-resistant and easy to deform. , to achieve good aging resistance, reduce the influence of thermal deformation, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

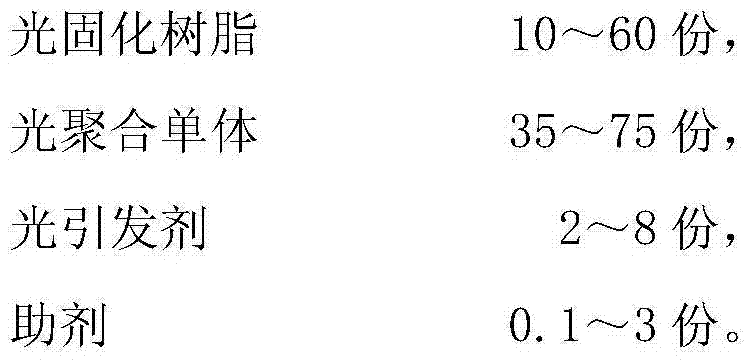

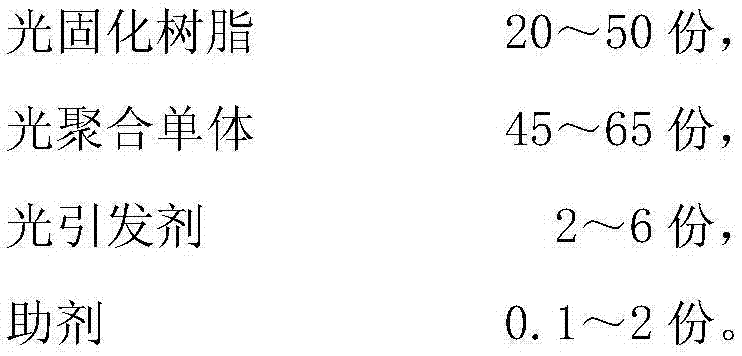

Method used

Image

Examples

Embodiment 1~9

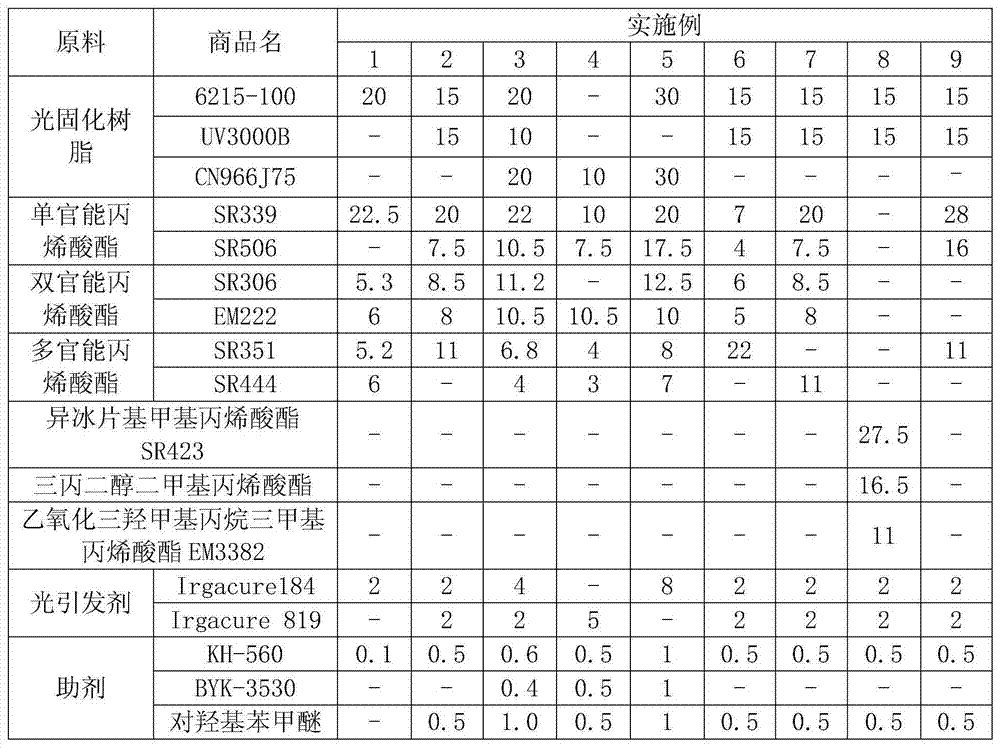

[0031] Embodiments 1 to 9 respectively provide UV-composite laser coating compositions, and the corresponding raw material components and parts by weight of each composition are shown in Table 1;

[0032] The raw material components corresponding to each embodiment were mixed according to their parts by weight, dispersed at a medium speed for 2 hours, and filtered to obtain the corresponding UV-composite laser coating composition.

[0033] Table 1

[0034]

[0035] The application of the UV-composite laser coating composition of the above embodiments 1~9 specifically comprises the following process steps:

[0036] (1) Coating process

[0037] The UV-composite laser coating composition is applied on the pre-treated base film evenly by a coating machine according to the requirements of coating machine viscosity, coating amount and coating effect. Adjust process parameters to ensure uniform coating of UV-composite laser coating composition;

[0038] (2) Molding process

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com