Intelligent laser remanufacturing method and system

A laser remanufacturing and intelligent technology, applied in the field of advanced manufacturing and automation, can solve problems such as adverse effects on the health of operators, lower production efficiency, cumbersome and time-consuming processes, etc., to shorten the production cycle, save judgment time, and reduce programming difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below through specific embodiments.

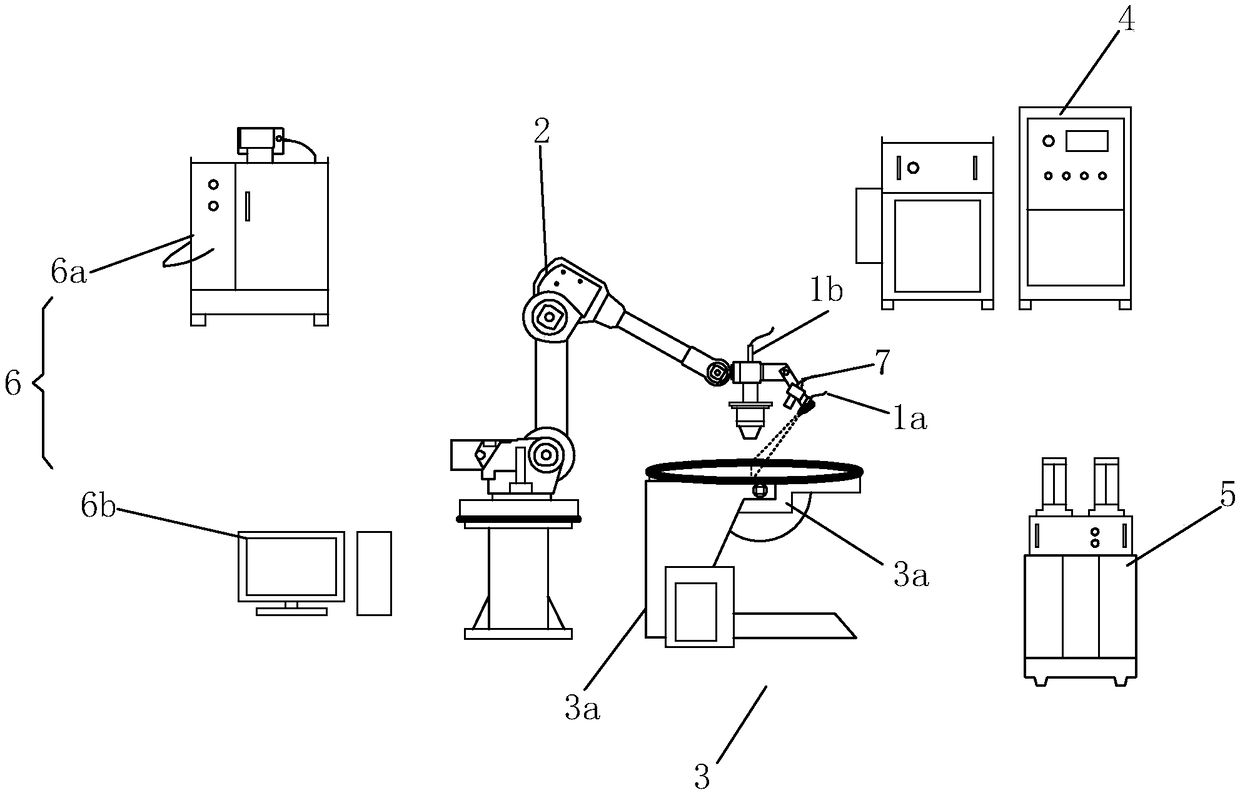

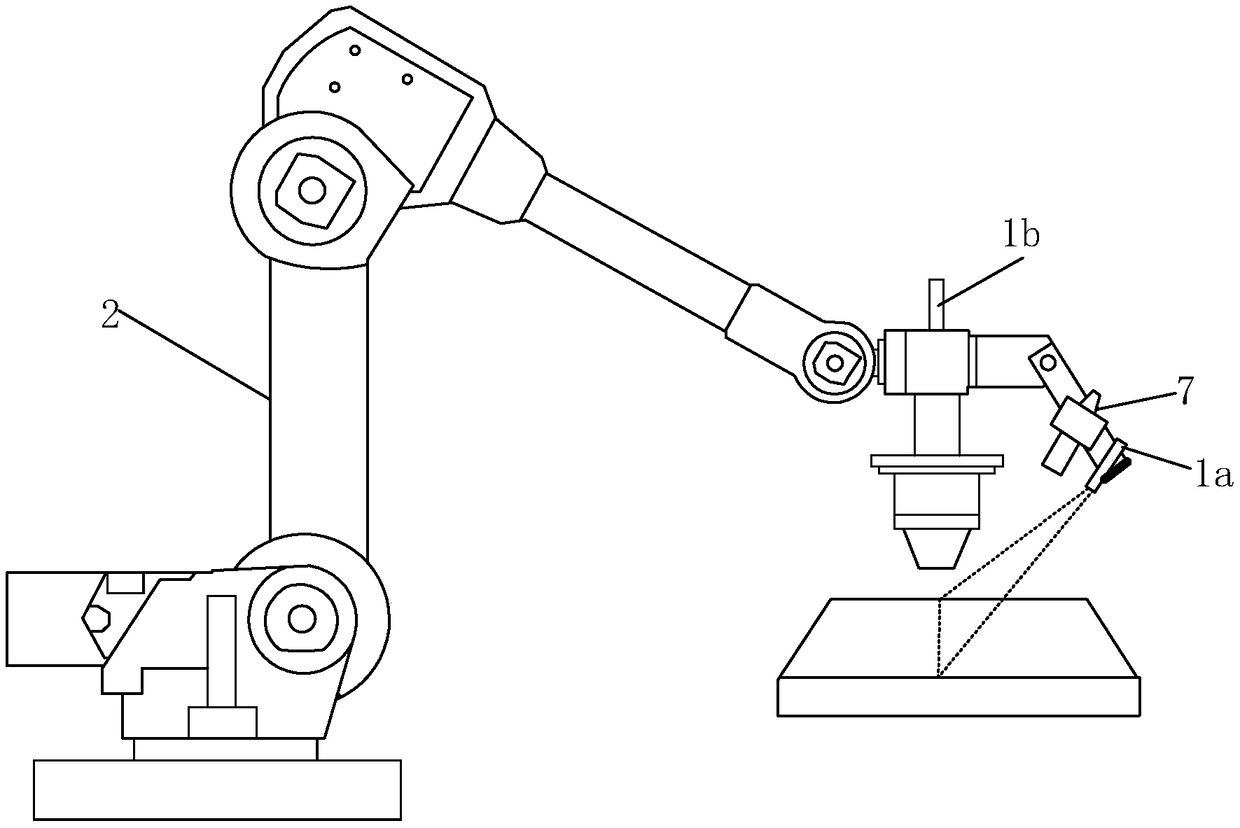

[0030] refer to figure 1 , figure 2 , is the main component of the intelligent laser remanufacturing system, including laser working head 1, CCD camera 7, six-axis industrial robot 2, positioner 3, laser 4, powder feeder 5 and control module 6, etc. The positioner 3 For adjusting the angle of the parts to be repaired, it includes a frame 3a and a workbench 3b, etc., the workbench 3b is used to place the connection to be repaired, and the frame 3a can control the action of the workbench 3b to adjust the angle of the parts to be repaired.

[0031] The six-axis industrial robot 2 is provided with a mechanical arm 2a, and the mechanical arm 2a can be moved and adjusted on six axes, and the six-axis industrial robot 2 commonly used in the market can be used. The laser working head is installed on the mechanical arm 2a, which includes a nozzle and a laser pointer 1a, and is used for cladd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com