Laser medical film and preparation method thereof

A laser and film technology, which is applied in the field of laser medical film and its preparation, can solve the problems of unsuitable laser printing output, poor high temperature resistance, follow-up paper, cards, etc., and achieve the effect of increasing speed, long storage period, and not easy to fade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

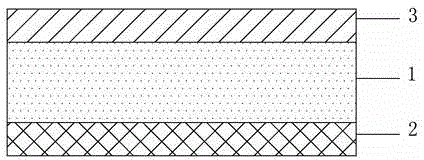

[0015] Such as figure 1 As shown, the film of the present invention is composed of three layers of PET film base (1), antistatic layer (2) and laser ink-absorbing coating (3). On the film base (1) made of PET material, one side is coated with An antistatic layer (2) made of polystyrene sulfonate, and the other side is coated with a laser ink-absorbing coating (3) containing a dispersion of nano-sized alumina powder.

[0016] The specific production steps of the film:

[0017] The first step prepares 10% polyvinyl alcohol solution, the degree of polymerization of polyvinyl alcohol is 3200, and the degree of alcoholysis is 83%;

[0018] The second step is to prepare antistatic liquid: add 25% polystyrene sulfonate solution to 60% polypropanol aqueous solution, and the mass ratio of polystyrene sulfonate solution to polypropanol aqueous solution is 1:1;

[0019] The third step is to apply the antistatic solution of the second step on one side of the PET substrate and dry it, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com