Cooler for cooling on-site welded joint of long steel rail and using method for cooler

A technology of on-site welding and welding joints, applied in tracks, track laying, track maintenance, etc., can solve problems such as low joints, increase maintenance workload, affect driving speed, etc., achieve fast cooling speed, ensure heat treatment quality, and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

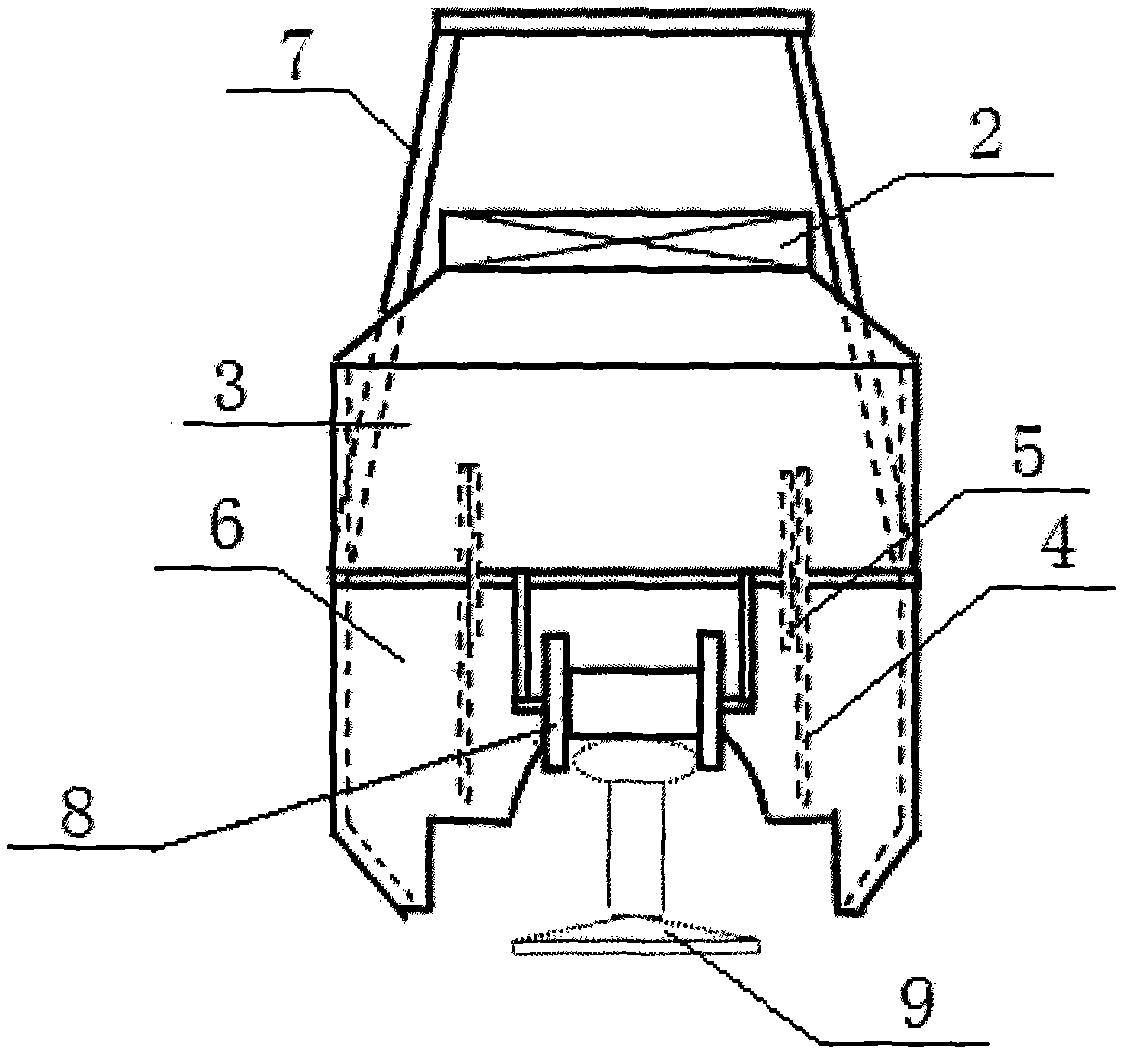

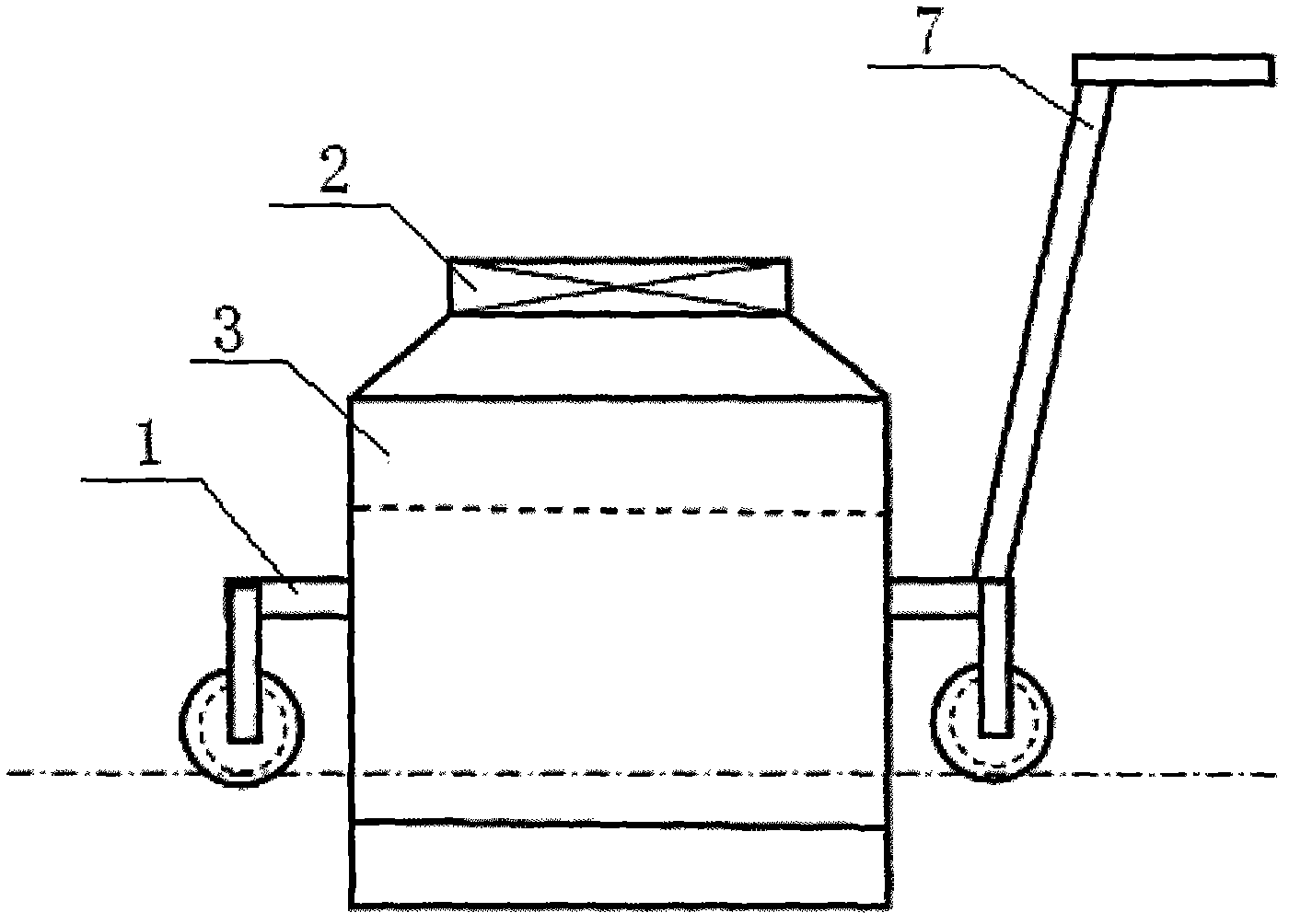

[0028] The accompanying drawings of the book further illustrate the present invention.

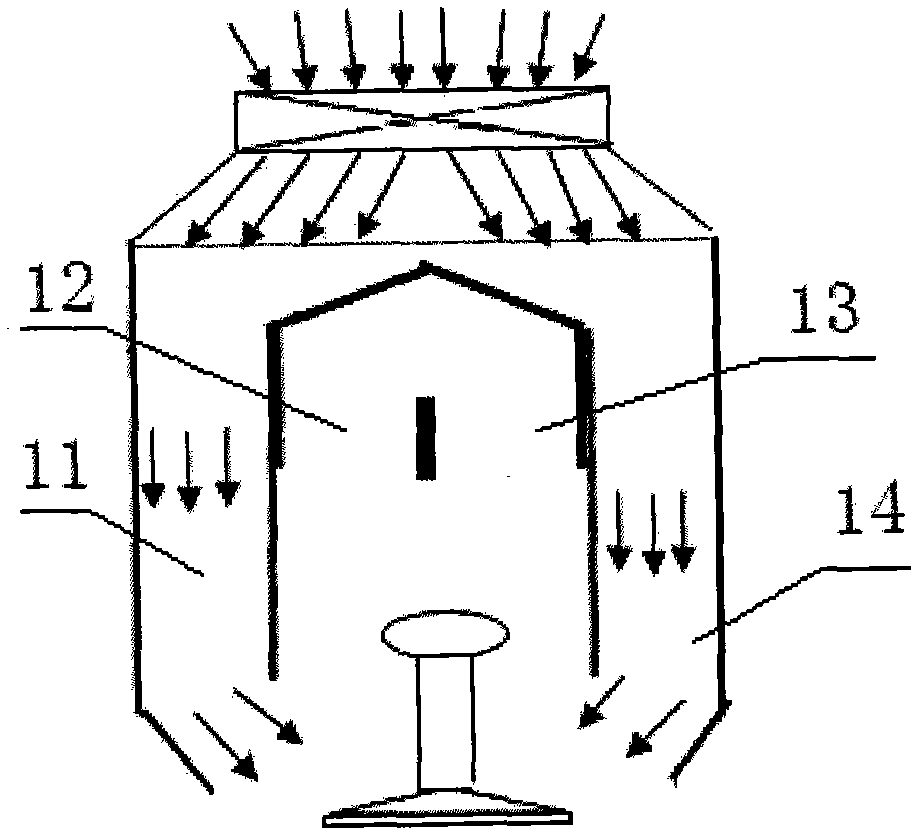

[0029] like Figure 1-2 As shown, a cooler for cooling welded joints of long rails on site is characterized in that it includes a traveling frame, a cooling fan, and a cooling air path distribution device. The cooling air path distribution device is fixed on the traveling frame, and the cooling air path A cooling fan is installed on the top of the distribution device;

[0030] The cooling air path distribution device is in the shape of a bottomless empty tank, the lower part of the tank body is folded inward, and an air path partition and an air path switch are arranged in the tank; the air path partition divides the tank body into multiple vertical spaces, and the air path The air circuit switch is movably connected to the top of the partition.

[0031] There are three partitions for the air passage, one central short partition is set in the center of the tank body, and the other two lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com