High-pressure valve material and heat treatment method thereof

A heat treatment method and body material technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of low strength, poor processing performance and corrosion resistance, high strength, etc., to facilitate cutting, reduce hardness, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

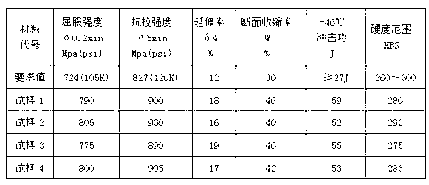

[0019] Embodiment 1: produce F125 valve body according to the following steps:

[0020] (1) Casting valve body blank: the valve body material is selected according to the following components: C 0.12%, Si 0.30%, Mn 0.50%, Cr 2.00%, Mo 0.90%, Fe 96.18%; the valve body blank is cast according to the process requirements;

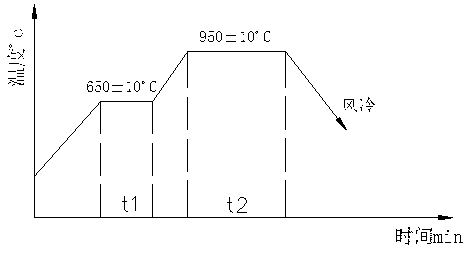

[0021] (2) Normalizing treatment of the valve body blank: preheat the valve body blank to 650±10°C and hold it for 65 minutes, then heat it to 950±10°C and hold it for 600 minutes, then take it out of the furnace and air cool it to room temperature;

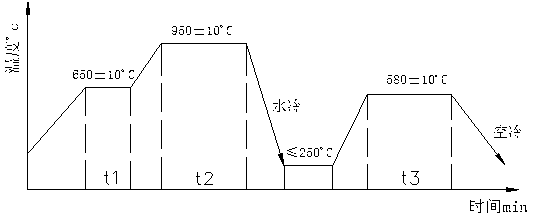

[0022] (3) Quenching and tempering treatment: Quenching and tempering treatment is carried out on the valve body blank after normalizing treatment. Quenching and tempering treatment includes quenching and tempering. Heat to 950±10°C, quench and hold for 200 minutes, then take out the furnace for water cooling, keep the F125 valve body in water for 15 minutes, the water temperature before quenching should be ≤38°C...

Embodiment 2

[0023] Embodiment 2: produce F125 valve body according to the following steps:

[0024] (1) Cast valve body blank: The valve body material is selected according to the following components: C 0.135%, Si 0.40%, Mn 0.55%, P≤0.0125%, S≤0.0125%, Cr 2.25%, Mo 0.95%, Fe 95.69% ;According to the process requirements, the valve body blank is cast;

[0025] (2) Normalizing treatment of the valve body blank: preheat the valve body blank to 650±10°C and hold it for 65 minutes, then heat it to 950±10°C and hold it for 600 minutes, then take it out of the furnace and air cool it to room temperature;

[0026] (3) Quenching and tempering treatment: Quenching and tempering treatment is carried out on the valve body blank after normalizing treatment. Quenching and tempering treatment includes quenching and tempering. Heat to 950±10°C for quenching and hold for 200 minutes, then take out the furnace for water cooling, keep the F125 valve body in water for 18 minutes, the water temperature befo...

Embodiment 3

[0027] Embodiment 3: produce F125 valve body according to the following steps:

[0028] (1) Cast valve body blank: The valve body material is selected according to the following components: C 0.15%, Si 0.50%, Mn 0.60%, P0.025%, S0.025%, Cr 2.50%, Mo 1.00%, Fe 95.2% ;According to the process requirements, the valve body blank is cast;

[0029] (2) Normalizing treatment of the valve body blank: preheat the valve body blank to 650±10°C and hold it for 65 minutes, then heat it to 950±10°C and hold it for 600 minutes, then take it out of the furnace and air cool it to room temperature;

[0030] (3) Quenching and tempering treatment: Quenching and tempering treatment is carried out on the valve body blank after normalizing treatment. Quenching and tempering treatment includes quenching and tempering. Heat to 950±10°C for quenching and heat preservation for 200 minutes, then take out the furnace for water cooling, keep the F125 valve body in water for 20 minutes, the water temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com