High-performance and high-corrosion-resistant mandrel hanger material and heat treatment method thereof

A heat treatment method and oil pipe hanging technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as hardness of difficult-to-insulate materials, and achieve the effect of reducing hardness, simple and easy process, and good hardness stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Produce F130 tubing hanger according to the following steps

[0022] (1) Forged tubing hanger blank: take the tubing hanger material according to the following components: C 0.10%, Si 0.20%, Mn 0.60%, P0.01%, S 0.01% Cr 12.50%, Mo 0.20%, Cu 0.1%, Ni 0.50%, V0.01%, Sn 0.10%, the sum of other trace elements ≤ 0.1%, and the rest is Fe; forging tubing hanging blanks according to process requirements;

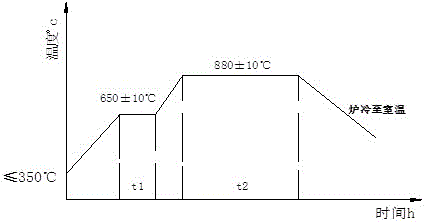

[0023] (2) Annealing treatment of tubing hanging blank: preheat the tubing hanging blank to 650±10°C and hold it for 100 minutes, then heat it to 880±10°C and hold it for 300 minutes, then cool it to room temperature;

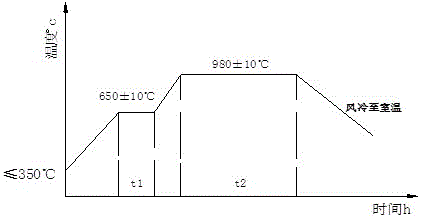

[0024] (3) Normalizing treatment of the oil pipe hanger blank: the oil pipe hanger blank is preheated to 650±10°C and held for 100 minutes, then heated to 980±10°C and held for 300 minutes, then taken out of the furnace and air cooled to room temperature;

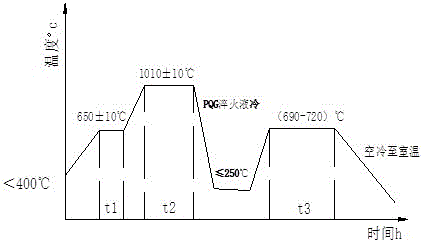

[0025] (4) Quenching and tempering treatment: After the normalizing treatment, the oil pi...

Embodiment 2

[0026] Embodiment 2: produce F130 tubing hanger according to the following steps:

[0027] (1) Forged tubing hanger blank: take the tubing hanger material according to the following components: C 0.13%, Si 0.30%, Mn 0.65%, P0.02%, S 0.02% Cr 13.00%, Mo 0.25%, Cu 0.15%, Ni 0.55%, V ≤ 0.05%, Sn 0.20%, the sum of other trace elements ≤ 0.1%, and the rest is Fe; the oil pipe hanger blank is obtained by forging according to the process requirements;

[0028] (2) Annealing treatment of tubing hanging blank: preheat the tubing hanging blank to 650±10°C and hold it for 100 minutes, then heat it to 880±10°C and hold it for 300 minutes, then cool it to room temperature;

[0029] (3) Normalizing treatment of the oil pipe hanger blank: the oil pipe hanger blank is preheated to 650±10°C and held for 100 minutes, then heated to 980±10°C and held for 300 minutes, then taken out of the furnace and air cooled to room temperature;

[0030] (4) Quenching and tempering treatment: After the norma...

Embodiment 3

[0031] Embodiment 3: The F130 tubing hanger is produced according to the following steps:

[0032] (1) Forged tubing hanger blank: take the tubing hanger material according to the following components: C 0.15%, Si 0.40%, Mn 0.70%, P0.025%, S 0.025% Cr 13.50%, Mo 0.30%, Cu 0.2%, Ni 0.60%, V0.1%, Sn 0.25%, the sum of other trace elements ≤ 0.1%, and the rest is Fe; the oil pipe hanger blank is forged according to the process requirements;

[0033] (2) Annealing treatment of tubing hanging blank: preheat the tubing hanging blank to 650±10°C and hold it for 100 minutes, then heat it to 880±10°C and hold it for 300 minutes, then cool it to room temperature;

[0034] (3) Normalizing treatment of the oil pipe hanger blank: the oil pipe hanger blank is preheated to 650±10°C and held for 100 minutes, then heated to 980±10°C and held for 300 minutes, then taken out of the furnace and air cooled to room temperature;

[0035] (4) Quenching and tempering treatment: After the normalizing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical performance | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| mechanical performance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com