Intelligent heat treatment production line

A production line, No. 1 technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control and other directions, can solve the problems of uncontrollable time of quenching workpiece into the medium, unable to meet the needs of mass production, uncontrollable product quality process, etc., to achieve savings The effect of over-reliance on labor, ensuring the quality of heat treatment, and accurately controlling the quenching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] This embodiment will be described in detail below in conjunction with the accompanying drawings.

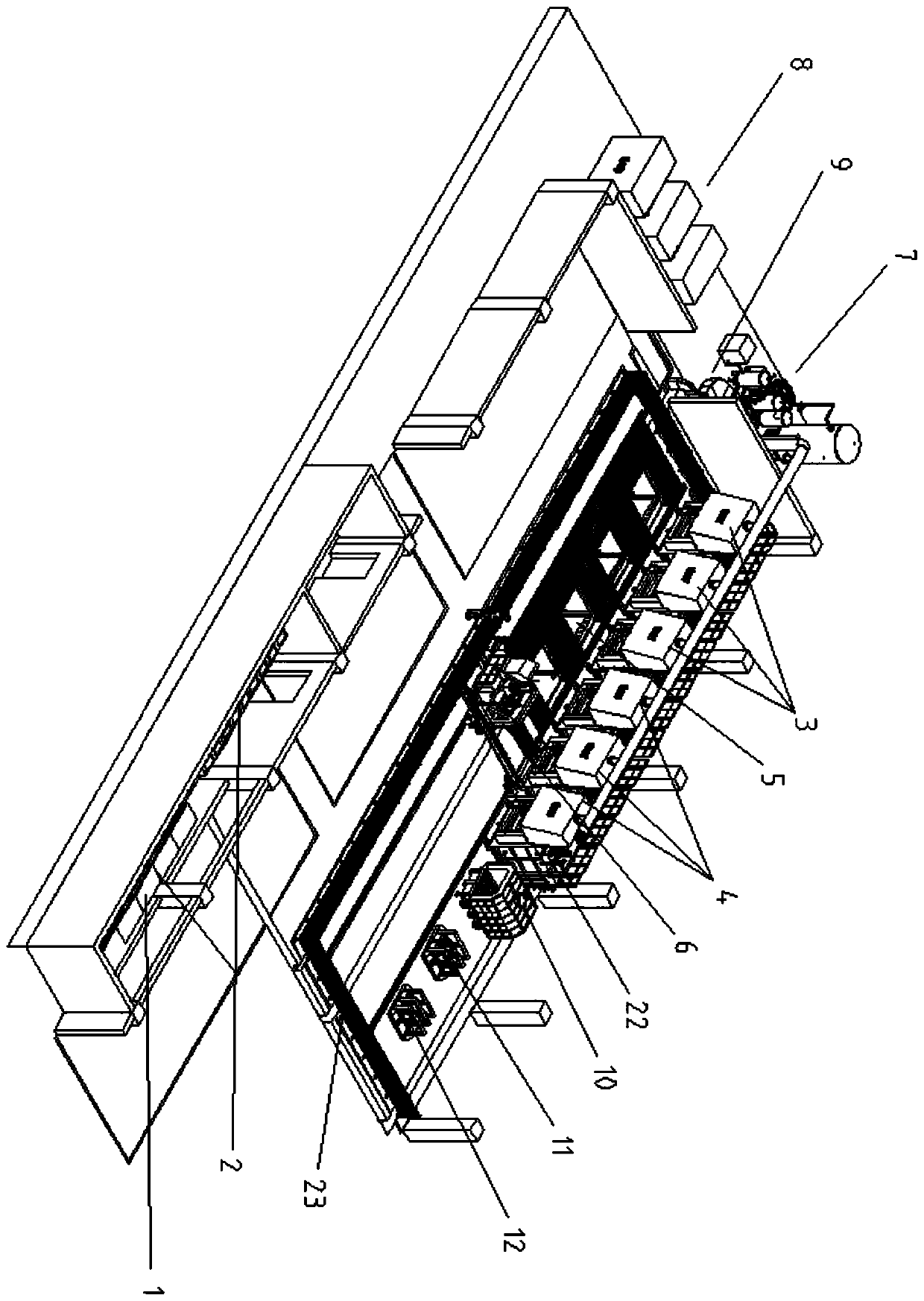

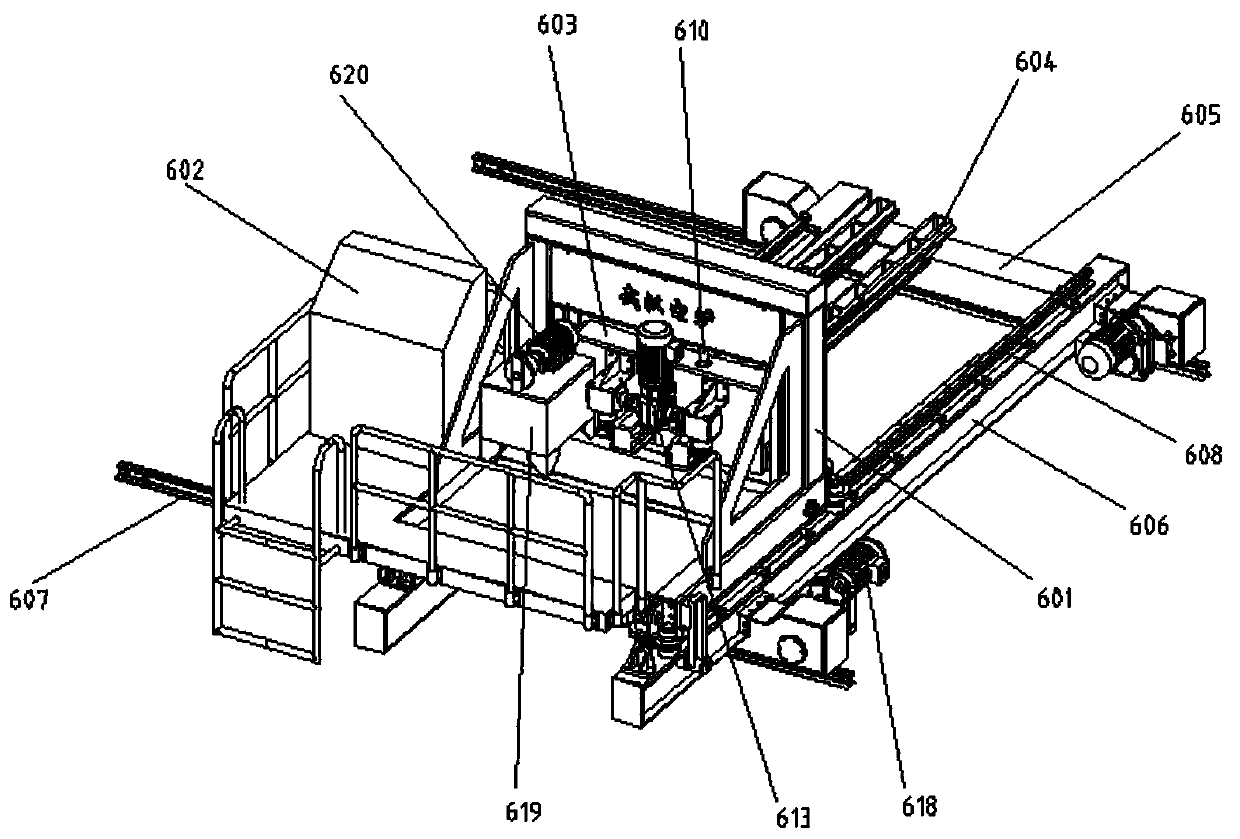

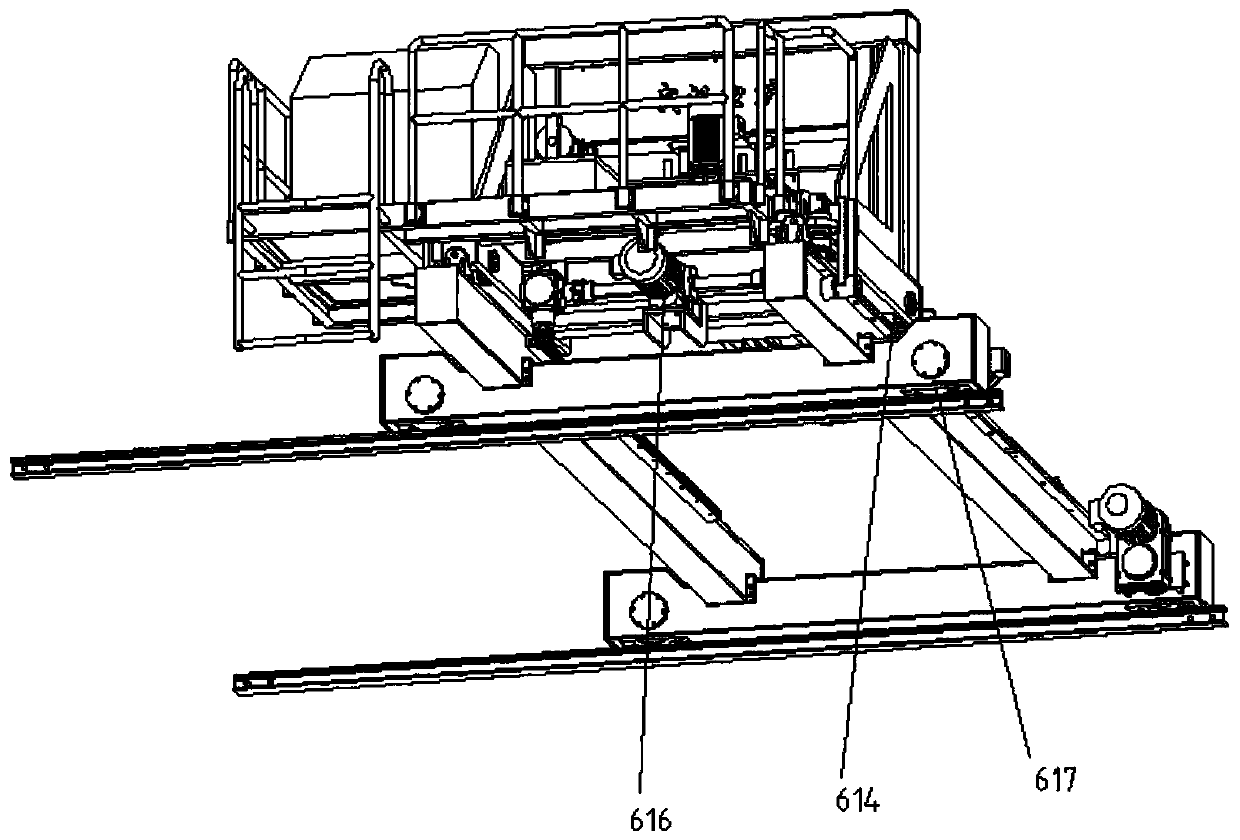

[0029] Such as figure 1 To such as Figure 10 As shown, an intelligent heat treatment production line includes an operation control center 1, a control cabinet system 2, multiple quenching furnaces 3 and tempering furnaces 4, an automatic lifting quenching tank 5, a transfer forklift 6, a nitrogen production system 7, and a cooling system 8 , waste gas purification system 9, normalizing station 10, loading station 11 and blanking station 12, the quenching furnace 3, tempering furnace 4, normalizing station 10, feeding station 11 and blanking station 12 in turn Arranged and arranged on a straight line, each quenching furnace 3 is provided with an automatic lifting quenching tank 5, the automatic lifting quenching tank 5 is arranged in parallel with the quenching furnace 3 and the upper surface of the automatic lifting quenching tank 5 is in line with the The installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com