Method for calculating position of highest temperature point of postweld heat treatment of 9-12% Cr martensitic heat-resistant steel vertical arrangement pipeline

A post-weld heat treatment, the highest temperature technology, applied in the direction of heat treatment furnace, heat treatment equipment, heat treatment process control, etc., can solve the problems of local temperature exceeding, no standard specification, and heat treatment effect can not be achieved, so as to avoid experiments and optimize heat treatment Technology, the effect of ensuring the quality of heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0037] Example.

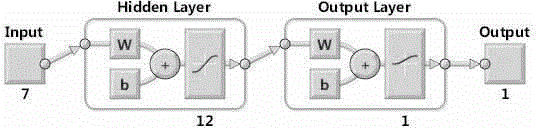

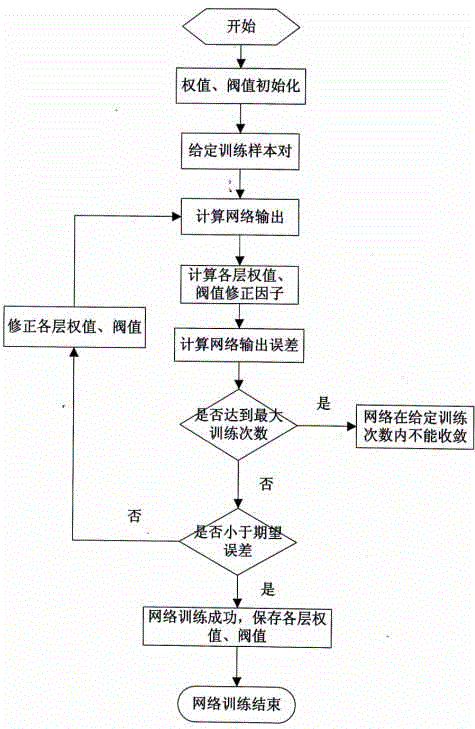

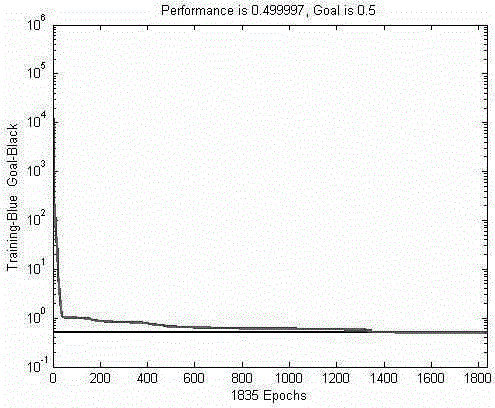

[0038] see Figure 1 to Figure 3 In this embodiment, the calculation method for the position of the highest temperature point of the post-weld heat treatment of vertically arranged pipelines of 9-12% Cr martensitic heat-resistant steel includes the following steps.

[0039] Step 1, the theoretical calculation module of the maximum temperature point. Under this module, based on the theory of heat transfer, the T group of 9-12%Cr martensitic heat-resistant steel pipes with different sizes is established in different heating widths, different insulation widths, different heat treatment ambient temperatures, and different heat treatment temperatures (temperature control temperature) As well as the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com