Carburizing steel bearing quenching mold

A carburizing steel and bearing technology, applied in quenching devices, manufacturing tools, heat treatment equipment, etc., can solve the problems of narrow oil groove, unqualified hardness of carburized steel bearing core, and low oil flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

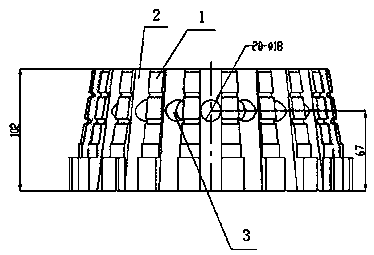

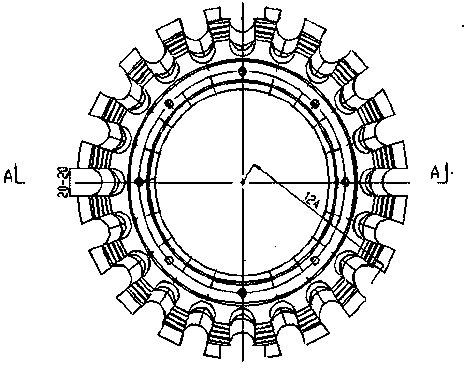

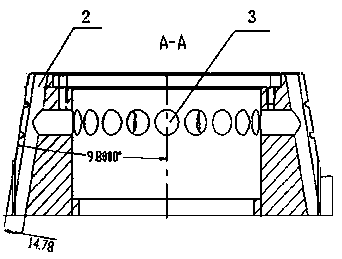

[0020] As shown in the figure, the carburizing steel bearing quenching mold includes an upper mold and a lower mold 1. The lower mold 1 is a truncated conical structure, and a number of oil passage grooves 2 are evenly opened in the circumferential side wall of the lower mold 1 in the longitudinal direction. In each oil passage groove 2 There is an oil hole 3 on it;

[0021] The oil through hole 3 is arranged in one-third of the entire lower mold 1;

[0022] Each of the oil through holes 3 is a transverse oil through hole of the lower mold 1, and each of the oil through holes 3 is set at the same horizontal height of the truncated cone;

[0023] The horizontal oil hole 3 is a closed structure, the outer diameter of the oil hole is 20mm, and the diameter of the end of the oil hole facing the oil inlet direction is 18mm;

[0024] The horizontal oil hole 3 of the mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com