Metal plate strip sectional type heat treatment device and technological method

A technology for heat treatment devices and metal strips, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems of difficult realization of cooling process, limited varieties and specifications, etc., and achieve improvement of flatness of plate shape and residual stress distribution, improving the uniformity of quenching, and increasing the cooling rate of quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

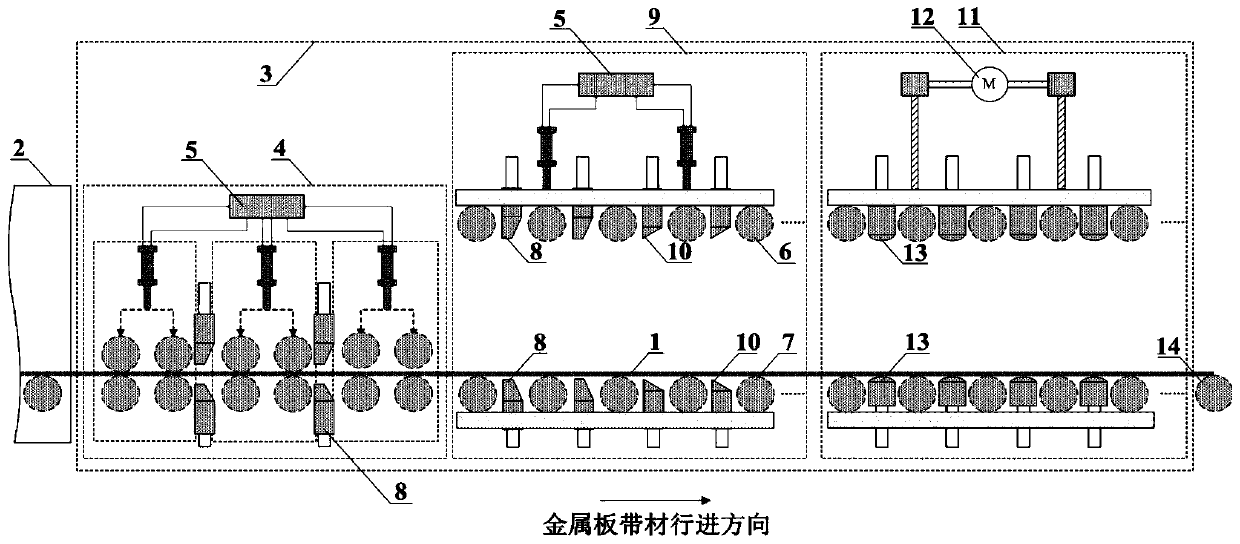

[0033] Such as figure 1 , 4 As shown, the metal plate strip 1 is heated to the process temperature in the roller hearth heat treatment furnace 2, and after reaching the holding time, it sends a request discharge signal to the segmental heat treatment device 3, and the segmental heat treatment device 3 receives the request for discharge After the signal, the hydraulic system of the roller press quenching device 4 adjusts the roll gap between the upper roller table 6 and the lower roller table 7 to 3.8-3.9 mm, and the first three sets of roller press quenching device 4 slit nozzles 8 middle cavity 15 spray water , the total spray volume is 1500~3000m 3 / h, water spray pressure 0.8MPa, all the upper roller table 6 and lower roller table 7 of the roller press quenching device 4 rotate forward, the linear speed is 0.3-0.7m / s, the hydraulic system of the high-pressure jet quenching device 9 will move the upper roller table The roll gap between 6 and the lower roller table 7 is adj...

Embodiment 2

[0036] In this embodiment, taking the quenching heat treatment of metal plates and strips with a thickness of 200 mm and a width of 3500 mm as an example, the specific implementation plan of the segmental heat treatment device and process method for metal plates and strips is described:

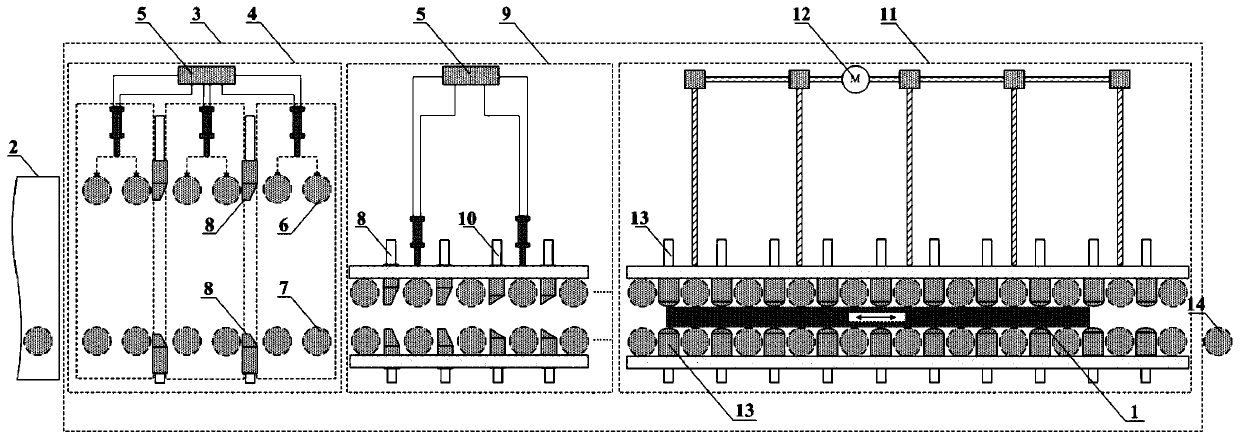

[0037] Such as figure 2 , 4 As shown, the metal plate strip 1 is heated to the process temperature in the roller hearth heat treatment furnace 2, and after reaching the holding time, it sends a request discharge signal to the segmental heat treatment device 3, and the segmental heat treatment device 3 receives the request for discharge After the signal, the hydraulic system of the high-pressure jet quenching device 9 adjusts the roll gap between the upper roller table 6 and the lower roller table 7 to 205-210 mm, and the high-pressure jet quenching device 9 has two sets of slit nozzles 8 and 6 groups of close-arranged round-hole jet nozzles Both the middle chamber 15 and the side chamber 16...

Embodiment 3

[0040] In this embodiment, taking the controlled cooling and heat treatment of metal plates and strips with a thickness of 50 mm and a width of 2500 mm as an example, the specific implementation plan of the segmental heat treatment device and process method for metal plates and strips is described:

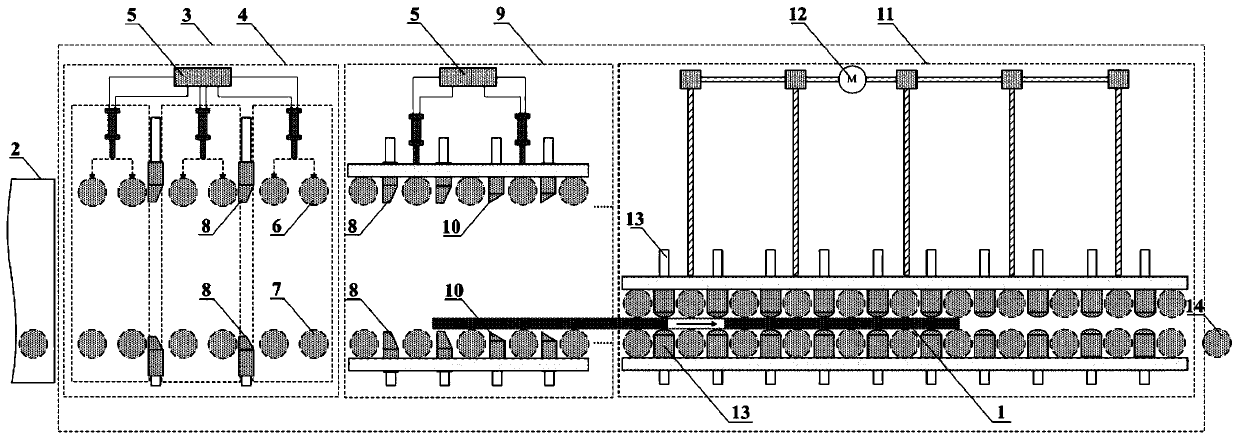

[0041] Such as image 3 , 4 As shown, the metal plate strip 1 is heated to the process temperature in the roller hearth heat treatment furnace 2, and after reaching the holding time, it sends a request discharge signal to the segmental heat treatment device 3, and the segmental heat treatment device 3 receives the request for discharge After the signal, the normal pressure continuous quenching device 11 electric lifting system 12 adjusts the roll gap between the upper roller table 6 and the lower roller table 7 to 51-55mm, and the front part of the normal pressure continuous quenching device 11 has 10-15 groups of round holes on the arc surface. The middle cavity 15 of the jet no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com