Shaft oxidation annealing furnace

An annealing furnace and pit-type technology, applied in the field of pit-type oxidation annealing furnaces, can solve the problems of inability to ensure no oxidation of products, poor uniformity of furnace temperature, etc., and achieve the effect of ensuring heat treatment quality and reducing heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

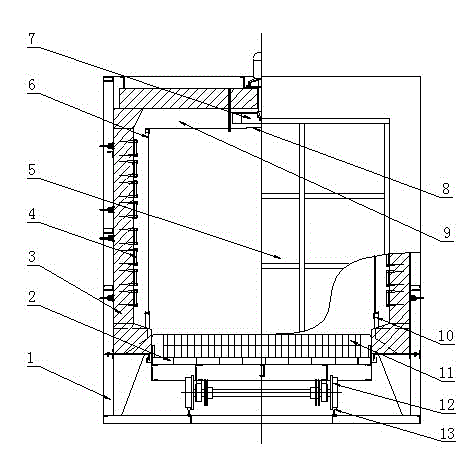

[0009] reference figure 1 As shown, a pit-type oxidation annealing furnace includes a furnace body 1. The furnace body 1 is composed of a baking zone 2 and a drying zone 3. The conveyor chain 4 passes through the furnace body 1 and enters the baking zone 2 and the drying zone. 3. Furnace entrance 5, heating wire 6, conveyor chain 4, sprocket 7 and drying oven connecting plate 8 constitute a drying zone; baking oven connecting plate 9, baking heating resistance rod 10, conveyor chain drive drum 11 and furnace body outlet The material opening 12 constitutes a baking zone; the baking zone 2 and the drying zone 3 are seamlessly connected through the baking oven connecting plate 9 and the drying oven connecting plate 8. The heating electric heating wire 6 and heating resistance rod 10 are both U-shaped design, the conveying chain 4 passes through the middle of the U, the heating electric heating wire 6 is close to the furnace wall in the drying zone 3, and the U-shaped upper and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com