Non-oxidation energy saving ageing furnace of nonferrous metal

A non-ferrous metal, non-oxidation technology, applied in furnaces, furnace types, heat treatment furnaces, etc., can solve the problems of non-ferrous metals without heat treatment advantages, poor furnace temperature uniformity, and low work efficiency, so as to ensure furnace temperature uniformity and heat treatment Quality, the effect of saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

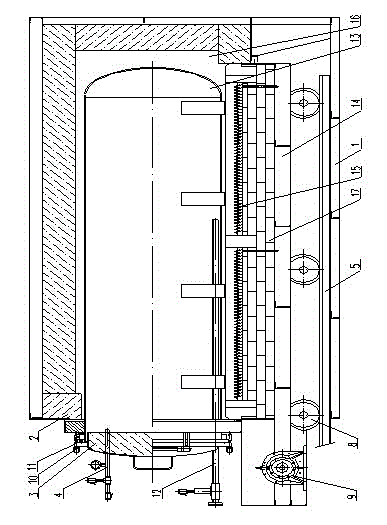

[0008] Depend on figure 1 As we know, the present invention includes a furnace frame 1, a furnace door 3, a furnace door lifting device 4, an inner idler roller 6, a sprocket transmission device 12, a feeding platform and a discharge trolley 8, and the furnace frame 1 is fixed with a standard ceramic fiber Blanket furnace lining 2, as the heat insulation material of the furnace 9, the thickness of the insulation layer is 200 mm, and its weight is only 1 / 20 of the refractory brick furnace body, and the insulation effect of the fiber furnace wall with a thickness of 200 mm is equivalent to that of a 464 thick brick furnace wall, but it can save energy by 25-30%, and the temperature rise of the outer wall of the furnace reaches the level of the standard medium and super furnace (ZBJ01004). The furnace door lifting device is composed of a motor, an electric hoist and a furnace door, and the motor and the electric hoist are connected with the furnace door.

[0009] During work, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com