A scanning probe microscope tip coated with a wax layer and its preparation method and application

A scanning probe and microscope technology, used in scanning probe microscopy, scanning probe technology, instruments, etc., can solve the problems of difficult removal of large pollutants, easy damage to modified layers, and damage to the tip of the needle tip. The realization method is simple and easy to operate, the surface of the needle tip is clean, and the cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 High / Low Melting Point Wax Removal Comparative Experiment

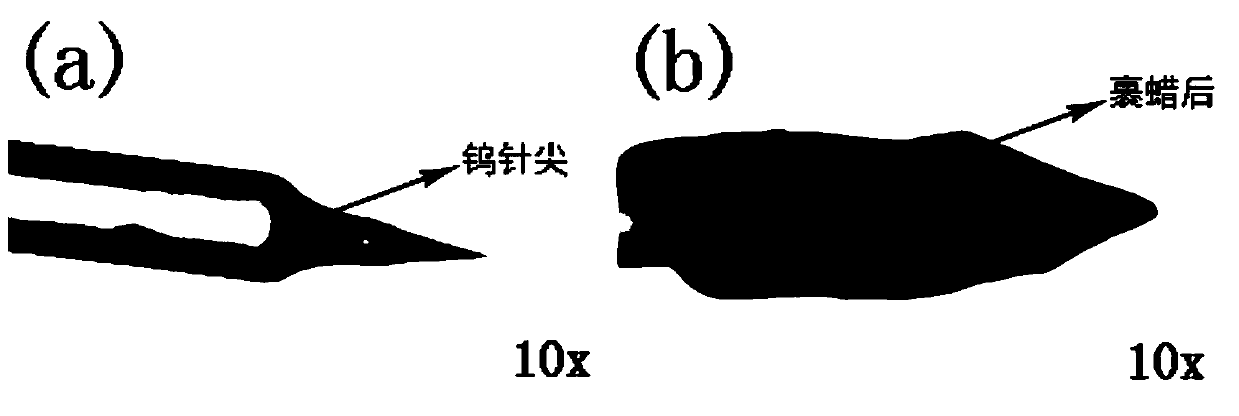

[0032] Put the low melting point paraffin into a clean container, heat the container until the solid paraffin is completely melted to the liquid paraffin, and the heating temperature is controlled near the melting point of the paraffin. The tungsten probe tip obtained by chemical etching ( figure 1 a) Submerge vertically below the liquid paraffin surface so that the needle tip is just submerged in the paraffin liquid surface. Immediately pull the tungsten probe out of the paraffin, and cool at room temperature to solidify the paraffin. The tungsten probe tip is pulled out from the liquid paraffin for a moment, and the liquid paraffin dipped on the surface of the tip solidifies immediately to form a solid wax protective layer on the surface of the tungsten tip (such as figure 1 shown in b).

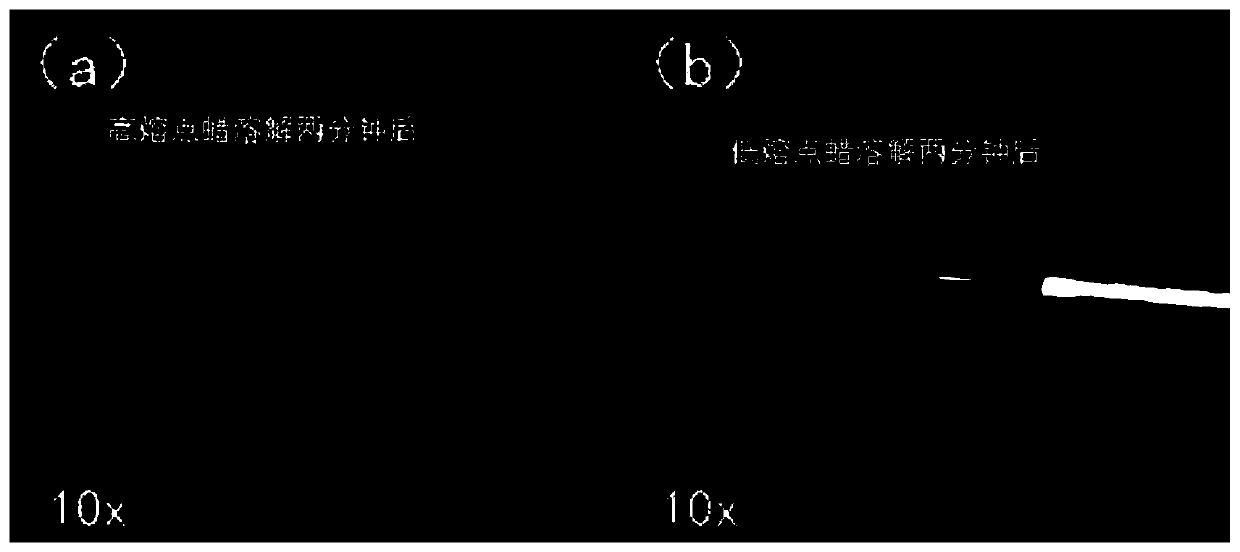

[0033] Fix the tip of the above-mentioned wax-coated tungsten needle so that the tip part is submerged in th...

Embodiment 2

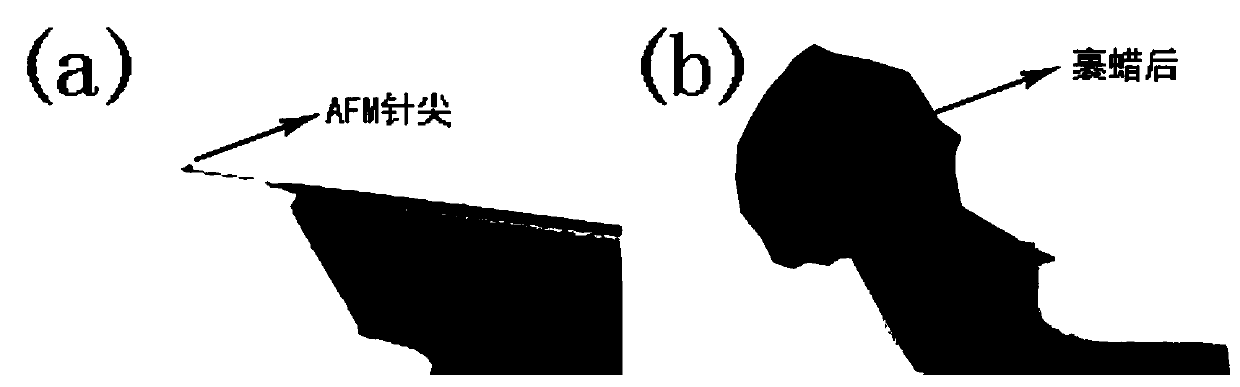

[0036] Put the low melting point paraffin into a clean container, heat the container until the solid paraffin is completely melted to the liquid paraffin, and the heating temperature is controlled near the melting point of the paraffin. The AFM probe ( figure 2a) The cantilever part is submerged vertically below the liquid paraffin surface, so that the needle tip is just submerged in the paraffin liquid surface. Immediately extract the AFM probe cantilever from the paraffin, and cool at room temperature until the paraffin solidifies. The AFM probe cantilever is pulled out of the liquid paraffin for a moment, and the liquid paraffin dipped on its surface solidifies immediately to form a solid wax protective layer on the surface of the cantilever ( figure 2 b).

[0037] The wax protective layer on the surface of the AFM probe cantilever covered with wax can be removed by infrared baking and melting to remove the wax: place the AFM probe covered with wax vertically on the bas...

Embodiment 3

[0039] Put the low melting point paraffin into a clean container, heat the container until the solid paraffin is completely melted to the liquid paraffin, and the heating temperature is controlled near the melting point of the paraffin. Submerge the cantilever part of the AFM probe vertically below the liquid paraffin surface, so that the needle tip is just submerged in the paraffin liquid surface. Immediately extract the AFM probe cantilever from the paraffin, and cool at room temperature until the paraffin solidifies. The AFM probe cantilever is pulled out from the liquid paraffin for a moment, and the liquid paraffin dipped on its surface solidifies immediately to form a solid wax protective layer on the surface of the cantilever (such as figure 2 shown in b).

[0040] The wax protective layer on the surface of the wax-coated AFM probe cantilever can be removed by dissolving the wax in an organic solvent: immerse the wax-coated AFM probe cantilever into the organic solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com