End induction heating device

An induction heating device and heating furnace technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of difficult control of heating time and heating degree, unsatisfactory heat treatment quality of workpieces, uneven heating of workpieces, etc. The effect of heat treatment quality, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

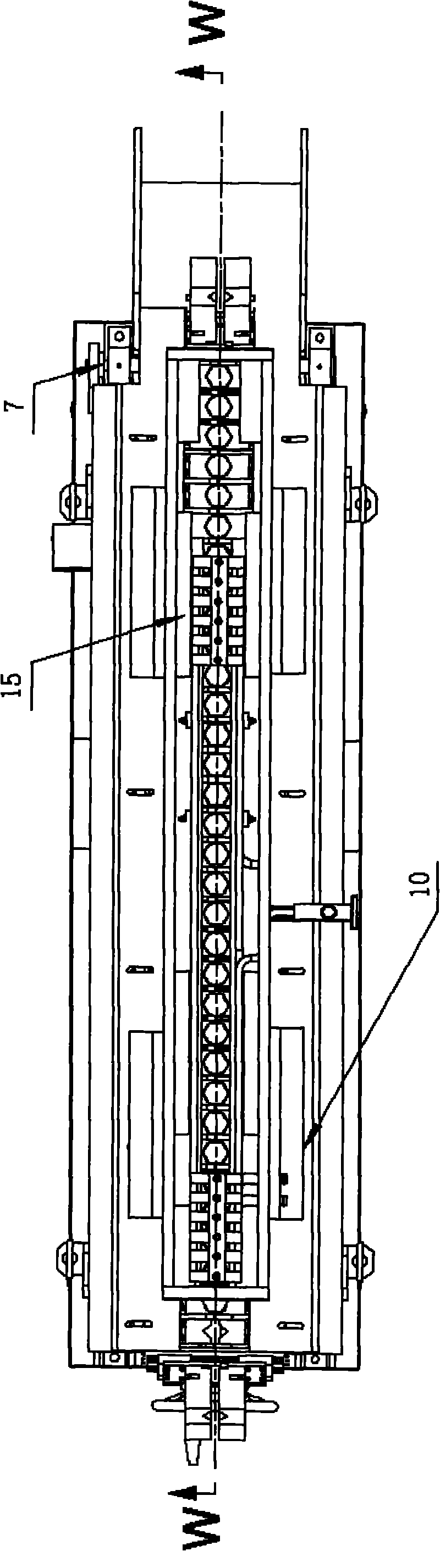

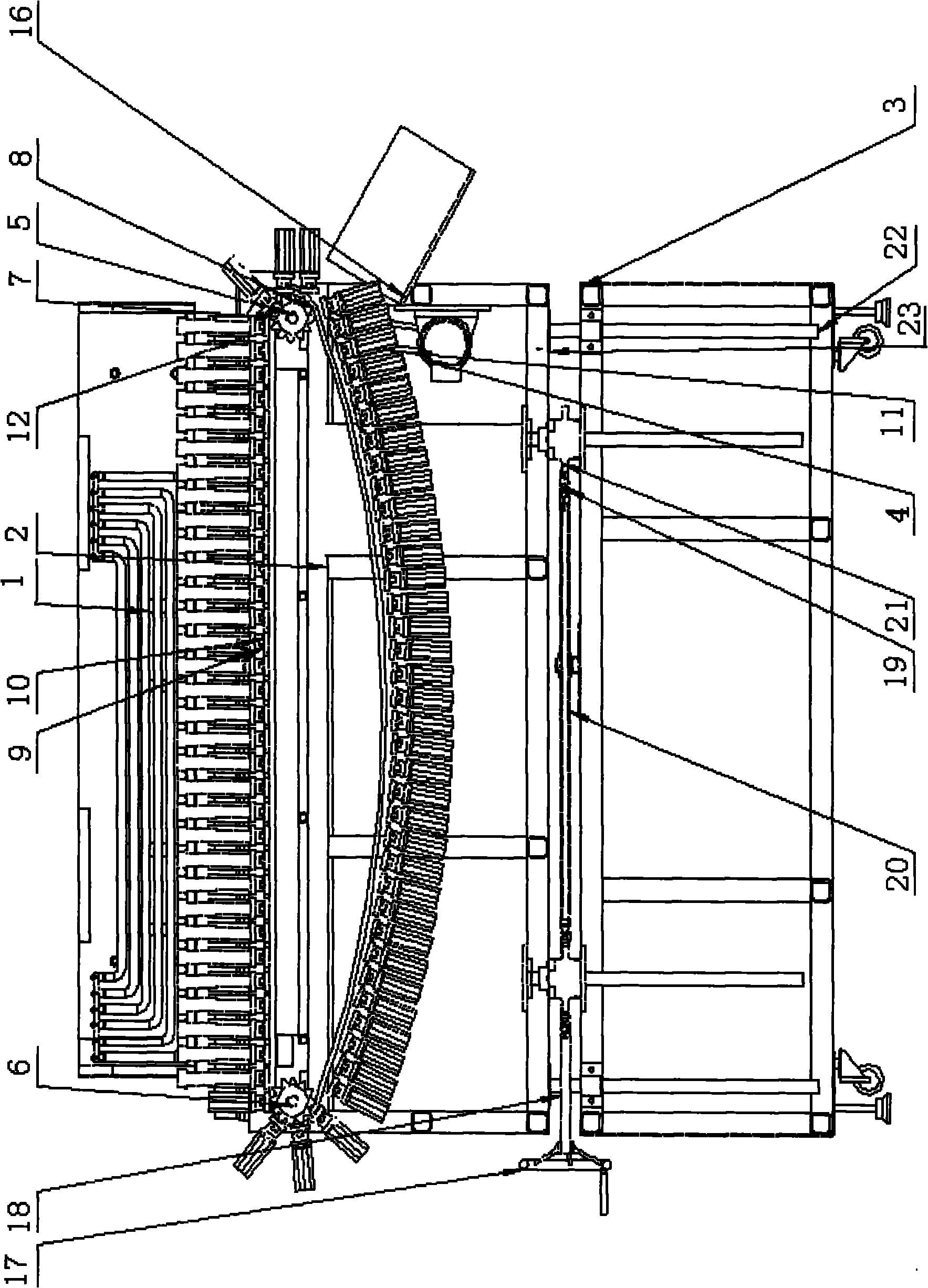

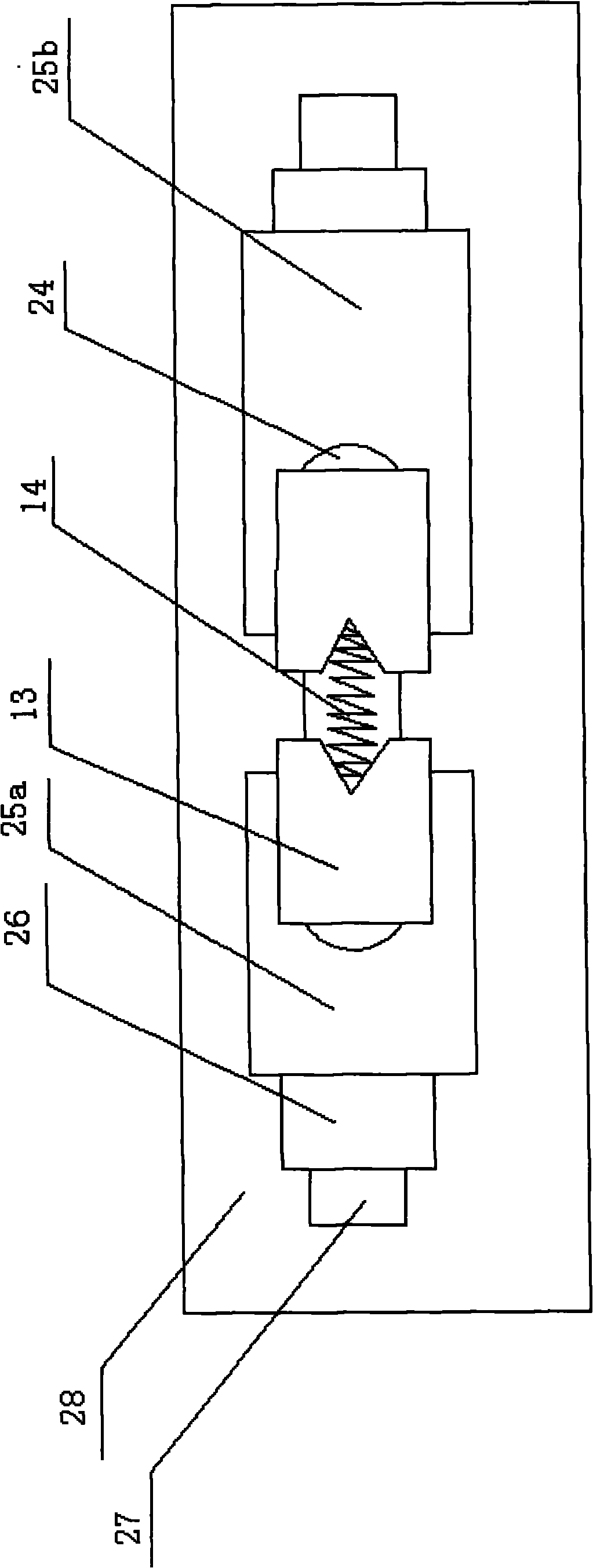

[0024] figure 1 It is a top view of the vertical feeder of the present invention; figure 2 for figure 1 W-direction view; image 3 It is a top view of the structure of the conveying device of the present invention.

[0025] Such as Figure 1 to Figure 3 Shown: the terminal induction heating device, including a U-shaped heating furnace 1 with an inverted cross section and a vertical conveyor, wherein the heating furnace 1 is located on the upper part of the vertical conveyor, and its U-shaped mouth is connected to the vertical conveyor The feeding ports of the machine correspond to each other. In addition, the vertical conveyor includes a transmission device, a feeding device, a lifting device, a positioning guide device, a frame 2 and a lifting platform 3, and the lifting device is arranged on the lifting platform 3. The transmission The device, the feeding device and the positioning and guiding device are arranged on the frame 2, and the frame 2 is located at the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com